In the realm of electrical engineering and infrastructure, ensuring reliable power distribution is paramount. As industries evolve and the demand for robust electrical solutions increases, the choice of cabling becomes a critical factor. According to a recent report by Grand View Research, the global armored cables market is projected to reach USD 15.9 billion by 2025, with a significant push driven by the rising demand for durable and safety-compliant electrical installations. Among various cable types, the Three Phase Armoured Cable stands out for its exceptional resilience and versatility in applications ranging from commercial buildings to industrial plants.

Three Phase Armoured Cables provide enhanced protection against mechanical damage and environmental factors, making them a preferred solution in scenarios where durability is paramount. Their design ensures not only safety but also efficiency in power distribution, which is crucial in maintaining operational continuity. Reports from Allied Market Research indicate that the use of armored cables is anticipated to grow rapidly, especially in sectors such as construction and manufacturing, where reliable electrical systems are vital. This growing trend underlines the importance of selecting the right type of Three Phase Armoured Cable to meet industry standards and performance expectations.

As we delve into the top options available for 2025, understanding these cables' benefits and applications will be essential for achieving optimal electrical solutions.

When it comes to industrial applications, selecting the right three-phase armoured cables is critical for ensuring durability and reliability in electrical systems. The market for these cables has grown substantially, driven by increased demand across various sectors, including manufacturing and construction. According to a recent report by MarketsandMarkets, the global armoured cable market is expected to reach USD 41.24 billion by 2025, with a significant portion attributed to the three-phase segment.

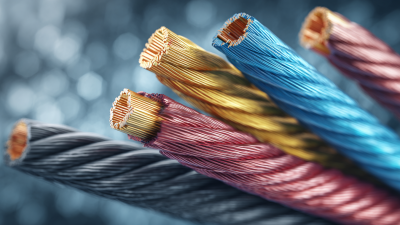

One of the top contenders in the three-phase armoured cable offerings is the Steel Wire Armoured (SWA) cable. Known for its robust construction, the SWA cable is designed to withstand harsh environmental conditions, making it an ideal choice for underground installations and areas with a high risk of mechanical impact. Additionally, the XLPE (Cross-Linked Polyethylene) insulated cables are gaining traction due to their excellent thermal and electrical properties, as evidenced by data from ResearchAndMarkets, which indicates an annual growth rate of 5.7% for XLPE cables in industrial usage.

Moreover, the increasing adoption of eco-friendly materials has led to the development of Low Smoke Zero Halogen (LSZH) armoured cables. These cables are particularly valuable in environments where fire safety is a major concern, as they minimize toxic smoke emissions during combustion. With the increasing regulatory pushes for sustainability, LSZH cables are expected to become a significant choice for industries aiming to comply with environmental standards while maintaining safety.

| Cable Type | Conductor Material | Voltage Rating (V) | Insulation Type | Typical Applications |

|---|---|---|---|---|

| Steel Wired Armoured (SWA) | Copper | 0-600 | XLPE | Underground Supply |

| Aluminium Armoured | Aluminium | 0-1000 | PVC | Industrial Equipment |

| Miner's Cable | Copper | 0-1000 | HFFR | Mining Operations |

| Armoured Flexible Cable | Copper | 0-600 | LSZH | Temporary Supply |

| PVC Armoured Cable | Aluminium/Copper | 0-1000 | PVC | Construction Sites |

When selecting three-phase armoured cables, several key features must be evaluated to ensure reliable electrical solutions. Firstly, the cable’s conductor material is essential; copper conductors, while costlier, are favored for their superior conductivity and durability compared to aluminum. According to a 2022 industry report by Research and Markets, the global market for copper wire and cables is projected to continue growing at a compound annual growth rate (CAGR) of 4.5%, underscoring the importance of high-quality materials in cable production.

Additionally, insulation and armoring are critical for protecting the cable from environmental factors and mechanical damage. Polyvinyl chloride (PVC) and cross-linked polyethylene (XLPE) are commonly used insulating materials due to their excellent dielectric properties and resistance to heat and chemicals. The same report highlights that cables with enhanced UV resistance and moisture-proof ratings are increasingly preferred in harsh industrial settings, contributing to their longevity and reliability. Furthermore, evaluating the voltage rating and the cable’s flexibility can help ensure that the chosen armoured cable meets specific operational requirements, ultimately leading to higher efficiency and safety in electrical installations.

The selection of the right three-phase armoured cable is crucial for ensuring reliable electrical solutions in various industrial applications. This comparative analysis highlights five of the top options available in 2025, taking into account key factors such as durability, flexibility, and resistance to environmental stressors.

Among the leading contenders, the XPLE-insulated cables stand out due to their excellent thermal characteristics, making them suitable for high-temperature applications without compromising safety.

Another strong candidate is the steel wire armoured (SWA) cable, known for its robust protection against mechanical damage. It is particularly favored in outdoor settings or areas prone to physical disturbances. Additionally, the LSF (Low Smoke and Fume) cables are gaining traction due to their safety features in the event of a fire, ensuring that smoke and toxic fumes are minimized.

A thorough evaluation of these options reveals that while each cable type has its distinct advantages, the choice ultimately hinges on specific project requirements, environmental conditions, and regulatory standards.

When considering electrical systems, the cost-effectiveness of three-phase armoured cables cannot be overstated. These cables not only provide superior durability and protection against environmental hazards but also offer long-term savings. Investing in three-phase armoured cables may result in lower maintenance costs and a reduced need for replacements, making them an economically sound choice for businesses and homeowners alike. Their robust construction ensures that they can withstand mechanical stresses, which is particularly beneficial for industrial applications.

Tips: When selecting three-phase armoured cables, consider the specific environmental conditions they will be exposed to, such as moisture and temperature extremes. Additionally, always evaluate the cable’s specifications against your system’s requirements to ensure optimal performance. Investing in higher-quality cables upfront can lead to significant savings over time due to reduced operational disruptions.

Moreover, the versatility of three-phase armoured cables allows them to be used across various applications, from commercial buildings to heavy industrial environments. This adaptability not only adds to their value but also means they can be part of a standardised approach in electrical installations, further enhancing cost efficiency.

When installing three phase armoured cables, ensuring proper technique is crucial for maximizing their performance and longevity. First, adequate planning is essential. Before installation, assess the site conditions, including environmental factors that could affect the cables, such as moisture or exposure to chemicals. Choosing a suitable route that minimizes bends and avoids obstacles will also prevent unnecessary stress on the cable, which could lead to damage over time.

Another key factor is the termination of the cables. Use high-quality connectors and ensure that all terminations are completed in a clean, dry environment to prevent corrosion and ensure a reliable connection. Furthermore, during installation, maintain the specified bend radius to avoid compromising the integrity of the cable's armouring. Regular testing after installation, such as insulation resistance tests, will help identify any issues and ensure that the cables are functioning at their best right from the start. By following these installation tips, you can enhance the reliability and efficiency of your electrical solutions with armoured cables.