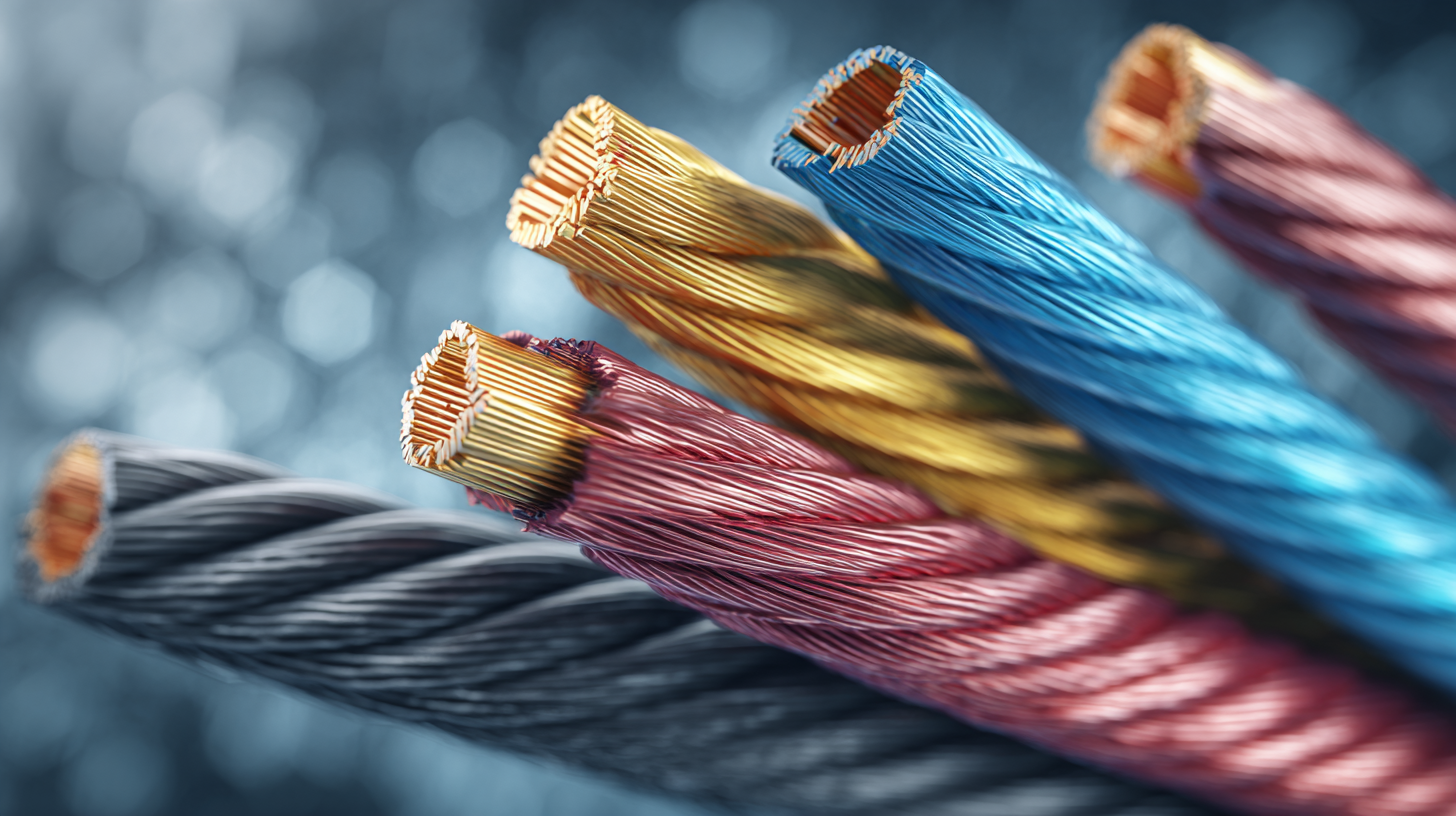

In the realm of modern electrical systems, the utilization of 3 Phase Armoured Cable has become increasingly essential, offering a robust solution for energy transmission in various applications. According to the latest industry reports, the global demand for armoured cables is projected to grow at a CAGR of 5.3% over the next five years, driven by the need for reliable and efficient power distribution infrastructures. The advantages of 3 Phase Armoured Cable, such as enhanced durability, resistance to environmental factors, and increased safety in hazardous locations, make it a preferred choice in sectors ranging from construction to renewable energy. This guide will delve into the myriad benefits and applications of 3 Phase Armoured Cable, providing insights into its critical role in advancing electrical systems amidst evolving technological demands.

3 Phase Armoured Cable plays a crucial role in modern industrial settings, offering a range of advantages that enhance safety and performance. One of the primary benefits is its robust construction, which provides excellent protection against mechanical damage, moisture, and other environmental factors. This durability ensures that the cable can withstand harsh conditions often found in factories and manufacturing environments, reducing the risk of outages and maintenance costs.

Additionally, 3 Phase Armoured Cable facilitates efficient power distribution by supporting higher electrical loads compared to single-phase systems. This capability is essential for industries that rely on heavy machinery and equipment, allowing for a more reliable and stable power supply. Moreover, the use of armoured cables minimizes electromagnetic interference, ensuring optimal performance of sensitive electronic equipment, which is critical for precision operations. As industries continue to evolve, the reliance on such advanced cabling solutions will only increase, making 3 Phase Armoured Cable an integral component in modern electrical systems.

Three-phase armoured cable is essential in modern infrastructure, offering enhanced durability and safety for electrical systems. Its robust construction, featuring an internal conductor insulated and encased in layers of protective materials, makes it ideal for diverse applications. According to a report by Research and Markets, the global market for industrial cables, including three-phase armoured cables, is expected to reach $32.9 billion by 2027, reflecting the increasing demand for robust electrical solutions in various sectors.

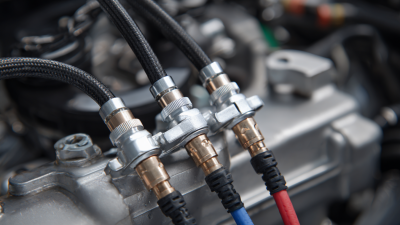

In industrial settings, three-phase armoured cables are commonly employed for power distribution and transmission in utilities, manufacturing, and construction. Their ability to handle high voltage and current loads makes them indispensable for operating heavy machinery, motors, and critical infrastructure. Additionally, these cables can be exposed to harsh environmental conditions, making them suitable for outdoor applications such as wind farms and solar power installations.

Tips: When selecting three-phase armoured cables, consider the specific environmental conditions they'll be exposed to, including temperature fluctuations and potential mechanical stress. Always ensure the chosen cable meets local standards and regulations to guarantee safety and compliance. Regularly inspecting the cables can also help in detecting wear and preventing potential failures.

The comparison of 3 phase armoured cable with traditional wiring solutions reveals significant advancements that enhance the efficiency and safety of electrical systems. Traditional wiring often lacks the robustness needed for demanding applications, making it susceptible to environmental factors and physical damage. In contrast, 3 phase armoured cable is designed with durable materials that provide increased protection and reliability. This makes it an ideal choice for industries where electrical integrity is paramount.

Recent innovations, such as the development of high-efficiency magnetic field energy harvesting from three-core cables, further demonstrate the potential benefits of modern wiring solutions. By optimizing the magnetic field characteristics of these cables, engineers can create systems that not only transmit power but also harness energy from their surroundings. This dual function not only enhances energy efficiency but also promotes sustainability in electrical systems. The integration of such technology marks a significant shift from traditional methods, showcasing the advantages of adopting 3 phase armoured cables in contemporary electrical infrastructure.

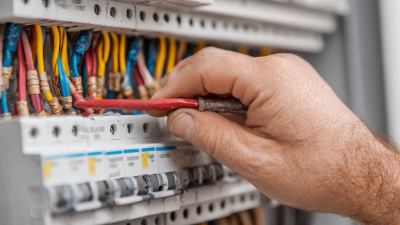

Installing 3 phase armoured cables presents several challenges that professionals must navigate to ensure reliable electrical systems. One primary challenge is the cable's weight and flexibility. These cables are heavier and less flexible than standard non-armoured types, making installation in tight spaces more difficult. Ensuring proper handling and installation techniques is crucial to prevent damage and maintain efficiency.

Another significant challenge is managing the environmental conditions where the cables will be installed. 3 phase armoured cables are often used in outdoor settings or harsh industrial environments, where exposure to moisture, chemicals, or extreme temperatures can occur. Proper selection of cable types with adequate insulation and waterproofing can mitigate these risks. Additionally, appropriate installation practices, such as securing cables with suitable clamps and supports, are essential to prevent stress or wear that could lead to failure over time. Addressing these challenges effectively allows for enhanced performance and longevity of the 3 phase armoured cables in modern electrical systems.

| Dimension | Description | Benefits | Challenges | Solutions |

|---|---|---|---|---|

| Material | Typically made with copper or aluminum conductors. | High conductivity and durability. | Risk of corrosion in harsh environments. | Use of anti-corrosion coatings. |

| Insulation | Layer of PVC or XLPE for electrical insulation. | Effective insulation and safety. | Extreme temperatures affecting insulation integrity. | Use cables rated for higher temperatures. |

| Mechanical Protection | Armoured with steel wire for physical protection. | Resistant to mechanical stress and damage. | Weight and rigidity can complicate installation. | Utilize lighter materials or modular designs. |

| Applications | Used in industrial, commercial, and residential setups. | Versatile use in various sectors. | Installation in confined spaces. | Plan installation routes ahead of time. |

| Compliance | Must meet IEC and BS standards. | Ensures safety and reliability. | Keeping up with changing regulations. | Regular training and updates for installers. |

The future of 3 phase armoured cable technology promises significant advancements driven by increasing demand for efficiency and safety in electrical systems. Innovations in materials are expected to enhance the durability and flexibility of these cables, allowing for better performance in harsh environmental conditions. With ongoing research into sustainable materials, the industry may witness a shift towards eco-friendly alternatives without compromising on the robustness that armoured cables offer.

Moreover, the integration of smart technology into electrical infrastructure will elevate the functionality of 3 phase armoured cables. Advanced monitoring systems could be embedded within the cables to track performance metrics and detect potential failures in real time. This capability will not only bolster reliability but also optimize maintenance schedules, significantly reducing downtime and operational costs. As industries look toward smarter, more resilient electrical solutions, the evolution of 3 phase armoured cable will play a crucial role in meeting these emerging challenges.