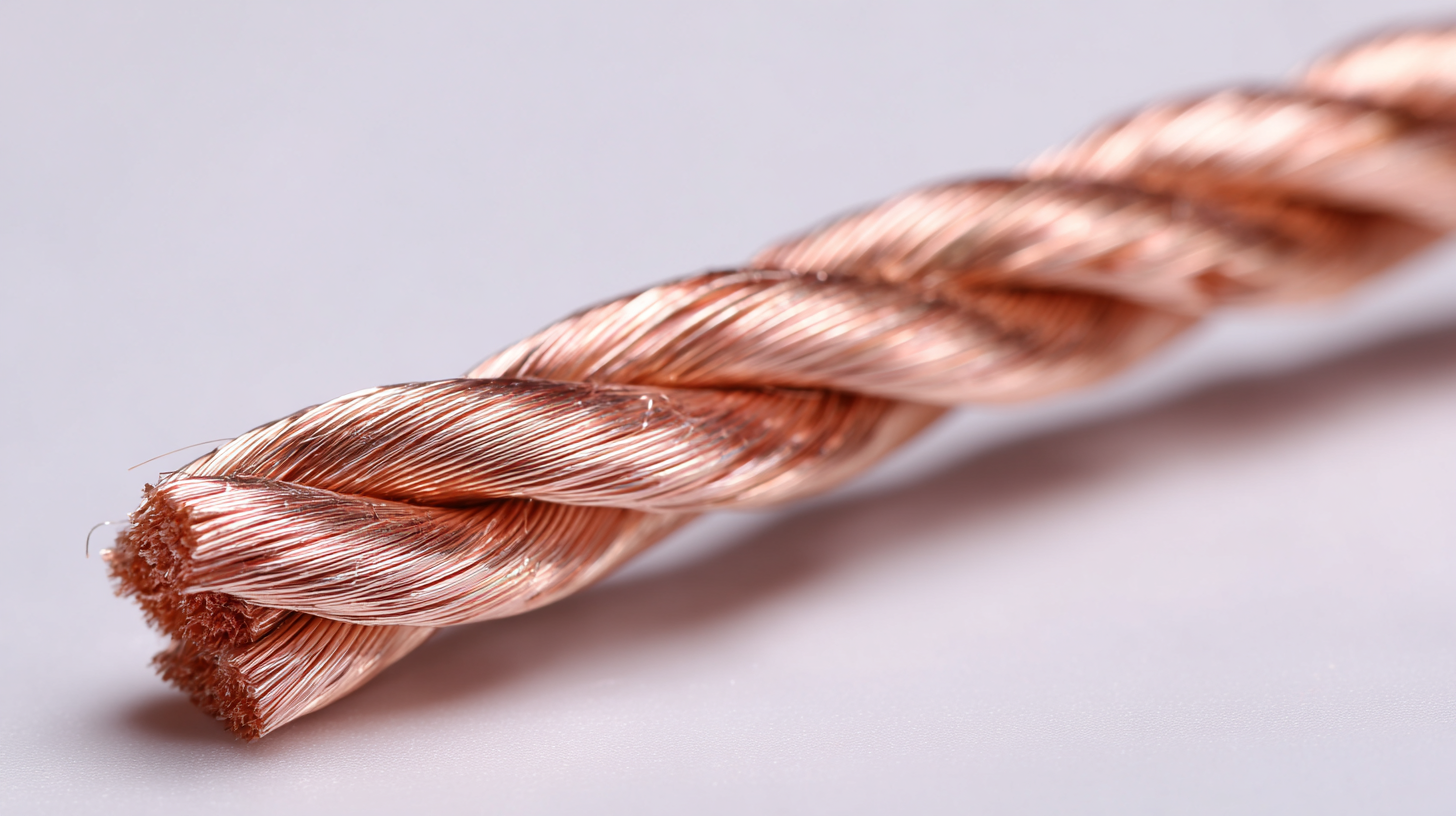

In today's fast-paced technological landscape, ensuring electrical safety and efficiency is paramount. One crucial component in achieving this goal is the use of Braided Copper Ground Wire. This innovative wiring solution is not only designed to improve the grounding of electrical systems but also to enhance the overall performance of electrical installations. By understanding the benefits associated with Braided Copper Ground Wire, homeowners, electricians, and engineers can make informed decisions that bolster safety measures and reduce the risk of electrical failures. Its unique structure allows for increased flexibility, superior conductivity, and resistance to corrosion, which collectively contribute to a more reliable and efficient grounding system. This guide will explore how you can harness the advantages of Braided Copper Ground Wire to optimize your electrical projects and enhance safety protocols, ensuring a secure and effective electrical environment.

Braided copper ground wire plays a crucial role in enhancing electrical safety standards, primarily due to its superior conductivity and resilience compared to traditional grounding methods. According to the Institute of Electrical and Electronics Engineers (IEEE), grounding systems using braided copper wire can reduce resistance levels by up to 60% compared to solid wire, significantly minimizing the risk of electrical faults. The increased surface area of the braided design allows for better heat dissipation, which is essential in preventing overheating and potential fire hazards. Furthermore, the flexibility of braided copper wire facilitates easy installation in various spaces, ensuring optimal grounding connections.

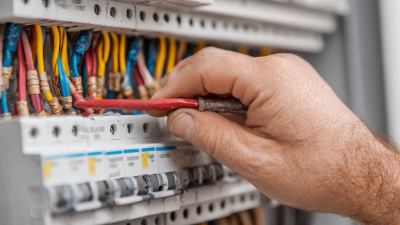

Tips: When selecting braided copper ground wire, ensure it meets the National Electrical Code (NEC) requirements for your specific application. This will not only enhance safety but also improve overall system efficiency. Regular inspections of grounding systems are also recommended, as studies show that up to 30% of electrical hazards can be traced back to improper grounding practices.

By investing in quality braided copper ground wire, businesses can achieve compliance with safety standards while safeguarding their electrical systems. Reports from the National Fire Protection Association (NFPA) indicate that proper grounding can significantly lower the incidence of electrical fires, underscoring the importance of this critical component in electrical installations.

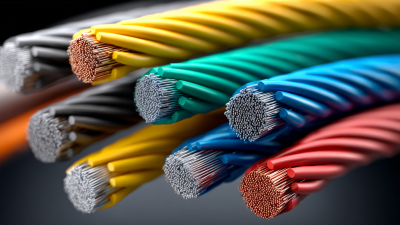

Braided copper ground wire is increasingly recognized for its superior performance in grounding systems. One of the key advantages of using this type of wire is its enhanced conductivity. The braided structure allows for multiple contact points, reducing resistance and improving the efficiency of electrical flow. This increased conductivity is crucial in grounding systems, as it helps ensure that excess electrical energy is safely channeled away, minimizing the risk of shock or fire hazards.

Another significant benefit of braided copper ground wire is its flexibility and durability. The braided design not only provides mechanical strength but also allows for easier installation, especially in tight or complex spaces. This flexibility makes it ideal for a variety of applications, ranging from industrial settings to residential systems. Moreover, copper's inherent resistance to corrosion ensures longevity, making it a reliable choice for maintaining electrical safety over time. In the face of environmental stresses, braided copper ground wire stands out as a resilient option that also supports efficient grounding operations.

When it comes to ensuring electrical safety, the installation of braided copper ground wire is a paramount consideration. According to the National Electrical Code (NEC), proper grounding is crucial for preventing electrical shocks and facilitating the safe operation of electrical systems. Braided copper wire offers superior conductivity compared to other materials, allowing for lower resistance and improved fault current handling. This quality not only enhances safety but also contributes to the overall efficiency of electrical installations.

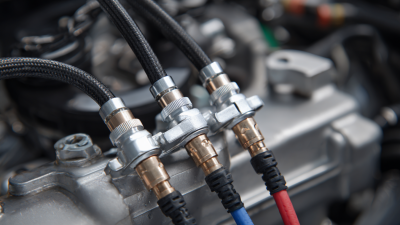

When installing braided copper ground wire, it’s essential to adhere to specific guidelines to maximize performance and safety. First, the wire should be securely connected to ground rods or grounding systems per NEC specifications, which typically recommend a minimum resistance of 25 ohms for grounding electrodes. Second, installers should ensure that the wire is free from corrosion and adequately insulated to prevent any physical damage. As per a report by the International Electrotechnical Commission (IEC), the effective grounding of electrical systems can reduce the likelihood of equipment failure and increase lifespan by up to 30%. Following these installation practices will significantly enhance both the safety and efficiency of electrical projects.

| Feature | Description | Benefits | Installation Guidelines |

|---|---|---|---|

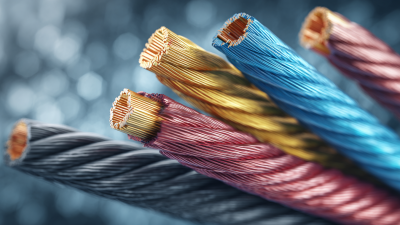

| Material | Made from multiple strands of copper for enhanced flexibility. | Improves conductivity and reduces chances of wire breakage. | Ensure that the strands are tightly twisted together before installation. |

| Corrosion Resistance | Braided for better resistance against environmental factors. | Increases lifespan and reliability in outdoor applications. | Use protective coatings if necessary to extend usability. |

| Grounding Efficiency | Provides a low-resistance path for fault currents. | Enhances electrical safety by reducing shock hazard. | Connect securely to ground rods and connectors to ensure effectiveness. |

| Flexibility | Easily bendable for use in tight spaces. | Facilitates installation in various configurations and settings. | Plan the layout before installation to minimize bends and turns. |

| Standards Compliance | Meets or exceeds electrical code requirements. | Provides peace of mind regarding safety and legal compliance. | Always verify compliance with local electrical codes before installation. |

To ensure the optimal performance of braided copper ground wire, regular maintenance is essential. First, it is important to inspect the grounding connections and hardware periodically for any signs of corrosion or wear. Corroded connections can significantly reduce the efficiency of electrical grounding, leading to potential safety hazards. Applying a suitable anti-corrosive compound to exposed metal surfaces can help prevent degradation and ensure long-term reliability.

Additionally, checking the installation integrity of the ground wire itself is crucial. This involves assessing the wire's condition for any physical damage, such as fraying or breaks, which may compromise its effectiveness. Regularly testing the ground resistance can also provide valuable insights into the performance of the grounding system. If any abnormalities are detected, timely repairs or replacements should be executed to maintain electrical safety standards. Keeping these maintenance practices in mind ensures that braided copper ground wire continues to function efficiently, safeguarding both equipment and personnel from electrical risks.

When evaluating grounding materials,  braided copper wire stands out for its superior electrical conductivity and flexibility compared to other options like solid copper and aluminum. The intricate weave of braided copper allows for a larger surface area, which enhances conductivity and provides effective grounding. This characteristic is particularly critical in environments where electrical efficiency is paramount, as reduced resistance leads to more reliable performance.

braided copper wire stands out for its superior electrical conductivity and flexibility compared to other options like solid copper and aluminum. The intricate weave of braided copper allows for a larger surface area, which enhances conductivity and provides effective grounding. This characteristic is particularly critical in environments where electrical efficiency is paramount, as reduced resistance leads to more reliable performance.

Tips for selecting the right grounding material include considering the installation environment—braided copper is ideal for tight spaces and applications requiring flexibility. Additionally, it's important to assess the current load demands; braided copper can handle higher loads more efficiently than traditional grounding materials. Always ensure that the connections made with braided copper wire are secure to prevent any potential grounding failures.

Furthermore, while aluminum may be lighter and less expensive, its susceptibility to corrosion can lead to long-term inefficiencies and safety hazards. In contrast, the durability of braided copper wire ensures longevity and consistent performance over time. When making your choice, prioritize materials that not only meet safety standards but also enhance the overall efficiency of your electrical systems.