In recent years, the electrical industry has increasingly recognized the critical role of XLPE cable insulation in enhancing the performance and reliability of modern electrical applications. According to a report by ResearchAndMarkets, the global XLPE cable market is projected to reach USD 48.5 billion by 2026, underscoring its growing importance in power distribution systems. XLPE, or cross-linked polyethylene, offers superior thermal, electrical, and mechanical properties compared to traditional insulation materials, enabling it to withstand higher temperatures and voltage levels. This insulation type is particularly vital in high-voltage applications, where the demand for safety, longevity, and efficiency is paramount. As utilities and industries shift toward greener energy solutions, the adoption of XLPE cable insulation is set to play a vital role in supporting the infrastructure needed for renewable energy integration. Understanding the benefits of XLPE cable insulation is essential for stakeholders aiming to optimize electrical systems for future demands.

The global market for Cross-Linked Polyethylene (XLPE) cables is on a promising trajectory, projected to grow from $35.84 billion in 2024 to $58.66 billion by 2032, boasting a robust CAGR of 6.35%. This steady growth reflects the increasing demand for efficient and reliable electrical systems, driven by advancements in technology and a strong emphasis on sustainability. XLPE insulation is particularly favored in modern electrical applications due to its excellent thermal and electrical properties, allowing for safer and more durable cable systems.

XLPE cables offer significant advantages for today's electrical systems, especially in the context of high-voltage direct current (HVDC) power transmission. The ability of XLPE to withstand higher temperatures and pressures without breaking down makes it ideal for critical applications, including underwater cabling and long-distance power transfer. Recent studies highlight the importance of investigating factors such as partial discharge and the impact of surface defects on electric field strength, ensuring that engineers can maximize the lifespan and efficiency of XLPE-insulated cables.

Tip: When selecting cables for modern applications, consider the specific environmental conditions and electrical demands. Enhanced properties like the DC breakdown strength of XLPE can have a significant impact on the safety and longevity of power systems. Implementing advanced materials, such as adaptive charge capture technology, can further optimize performance and reliability.

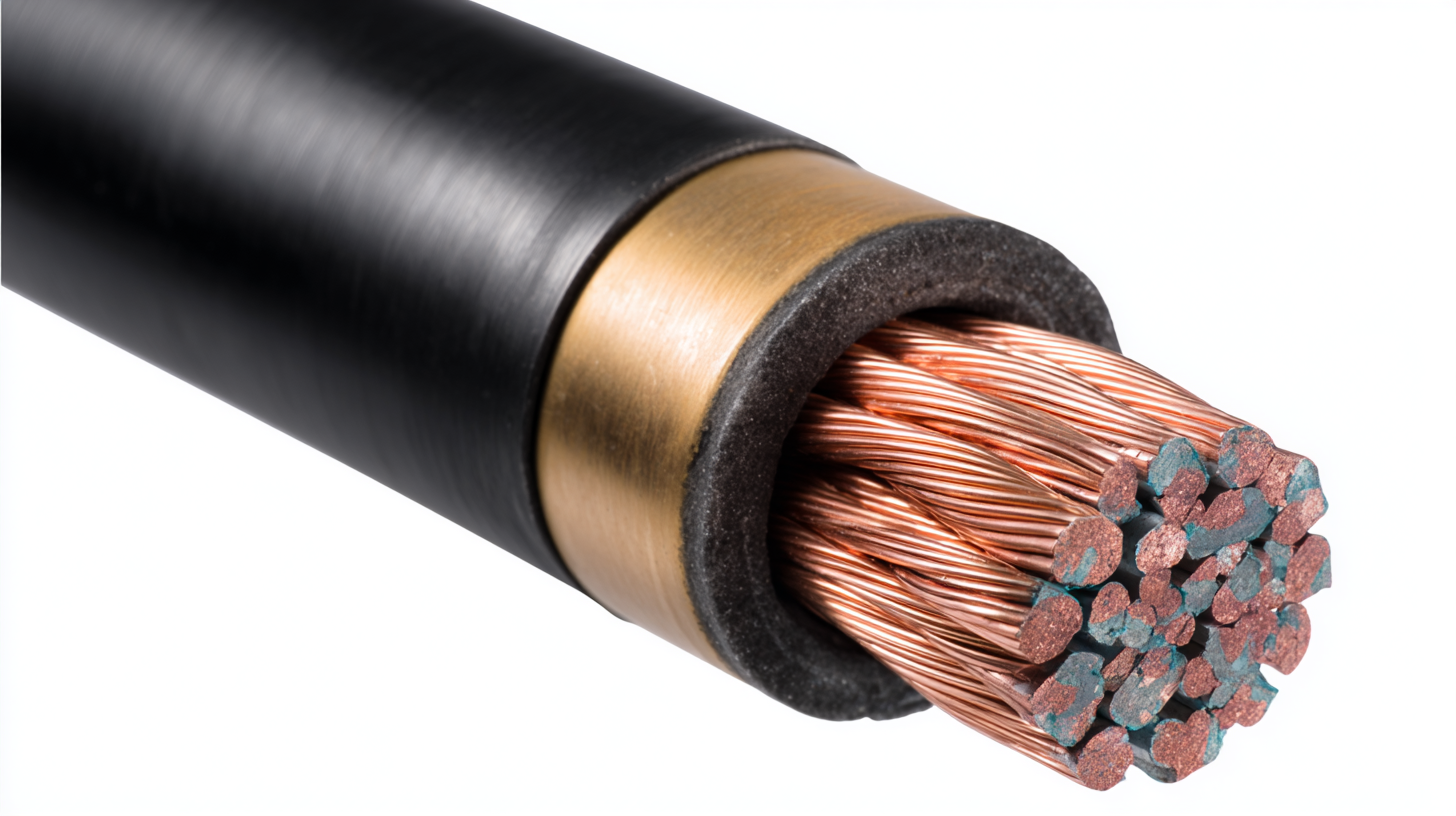

XLPE (cross-linked polyethylene) cable insulation has become a vital component in modern electrical applications due to its distinct advantages over traditional materials. One of its key properties is the excellent thermal stability it offers, which is essential for maintaining performance under high-voltage conditions. According to a report from the International Electrotechnical Commission (IEC), XLPE cables can withstand temperatures up to 90°C, with short circuit conditions extending to 250°C, providing a significant safety margin during peak operational stresses. This makes XLPE an optimal choice for power transmission in urban areas where heat management is crucial.

Moreover, XLPE insulation exhibits remarkable resistance to both moisture and chemical deterioration, enhancing its longevity and reliability. A study published in the Journal of Electrical Engineering highlighted that XLPE cables have a lower water absorption rate compared to EPR (ethylene propylene rubber) cables, which leads to reduced risk of insulation failure. Additionally, its low dielectric loss contributes to improved energy efficiency, achieving operational performance that meets the latest industry standards. Investing in XLPE insulation thus not only ensures enhanced electrical performance but also aligns with sustainability goals by reducing energy losses for utilities.

This chart illustrates the key properties of XLPE materials used in modern electrical applications, highlighting the advantages of XLPE cable insulation over traditional materials.

Cross-linked polyethylene (XLPE) insulation has become the preferred choice for modern electrical applications, primarily due to its superior properties compared to traditional cable insulations like PVC and rubber. According to the International Electrotechnical Commission, XLPE cables can operate at higher temperatures, often up to 90°C, with short-term overload capabilities reaching 130°C, while traditional insulations typically manage only 70°C. This enhanced thermal resistance allows for increased efficiency and improved load management in power systems, which is essential in today’s high-demand environments.

Furthermore, XLPE has significantly better electrical characteristics, including lower dielectric losses and enhanced insulation resistance. Data from the Electric Power Research Institute indicates that XLPE cables exhibit a dielectric strength of around 20-30 kV/mm, compared to 15-20 kV/mm for PVC. This translates to increased safety and reliability in electrical systems, reducing the risk of failures and outages. Additionally, XLPE is more resistant to moisture and chemicals, providing a longer lifespan, which can reduce replacement and maintenance costs significantly, supporting sustainable practices in electrical infrastructure development.

XLPE (cross-linked polyethylene) cables have become increasingly popular across various industry sectors due to their excellent thermal properties, chemical resistance, and mechanical strength. As industries continue to modernize and focus on energy efficiency, XLPE cables are well-suited for applications in power generation, distribution, and renewable energy systems. The global market for XLPE cables is projected to grow significantly, increasing from $35.84 billion in 2024 to $58.66 billion by 2032, with a compound annual growth rate (CAGR) of 6.35%. This growth highlights the expanding demand for advanced insulation solutions in electrical applications.

In the construction and infrastructure sectors, XLPE cables are widely used because of their ability to withstand high temperatures and environmental stressors. This makes them ideal for both underground and overhead installations. Furthermore, in the renewable energy market, especially in solar and wind energy projects, the reliability and performance of XLPE insulation help optimize the efficiency of power transmission. With the anticipated growth across various sectors, XLPE cables will play a crucial role in ensuring the sustainability and reliability of future electrical systems.

XLPE (cross-linked polyethylene) insulation has emerged as a game-changer in the field of electrical applications, particularly regarding the maintenance and longevity of cables in harsh environments. The superior thermal and chemical resistance of XLPE makes it an ideal choice for medium voltage applications where cables are exposed to extreme temperatures and aggressive substances. Recent advancements in cable manufacturing, highlighted in the market analysis, show that these insulation materials significantly enhance both performance and lifespan. It is projected that the wire and cable insulation and jacketing market will see growth from USD 45.67 billion in 2024 to USD 78.90 billion by 2033, driven partly by the increasing demand for high-quality insulation solutions.

Furthermore, the durability of XLPE insulated cables is vital for industries operating in challenging conditions. The robust characteristics of XLPE help protect cables from environmental stressors such as moisture, UV exposure, and mechanical wear, thus reducing the frequency and cost of maintenance. The growing emphasis on sustainability and efficiency, as reflected in recent market forecasts, underscores the urgency for companies to adopt advanced cable technologies that contribute to both operational longevity and cost-effectiveness in the long run. As industries continue to evolve, the reliance on XLPE cables is expected to rise, reaffirming their critical role in ensuring electrical safety and reliability.