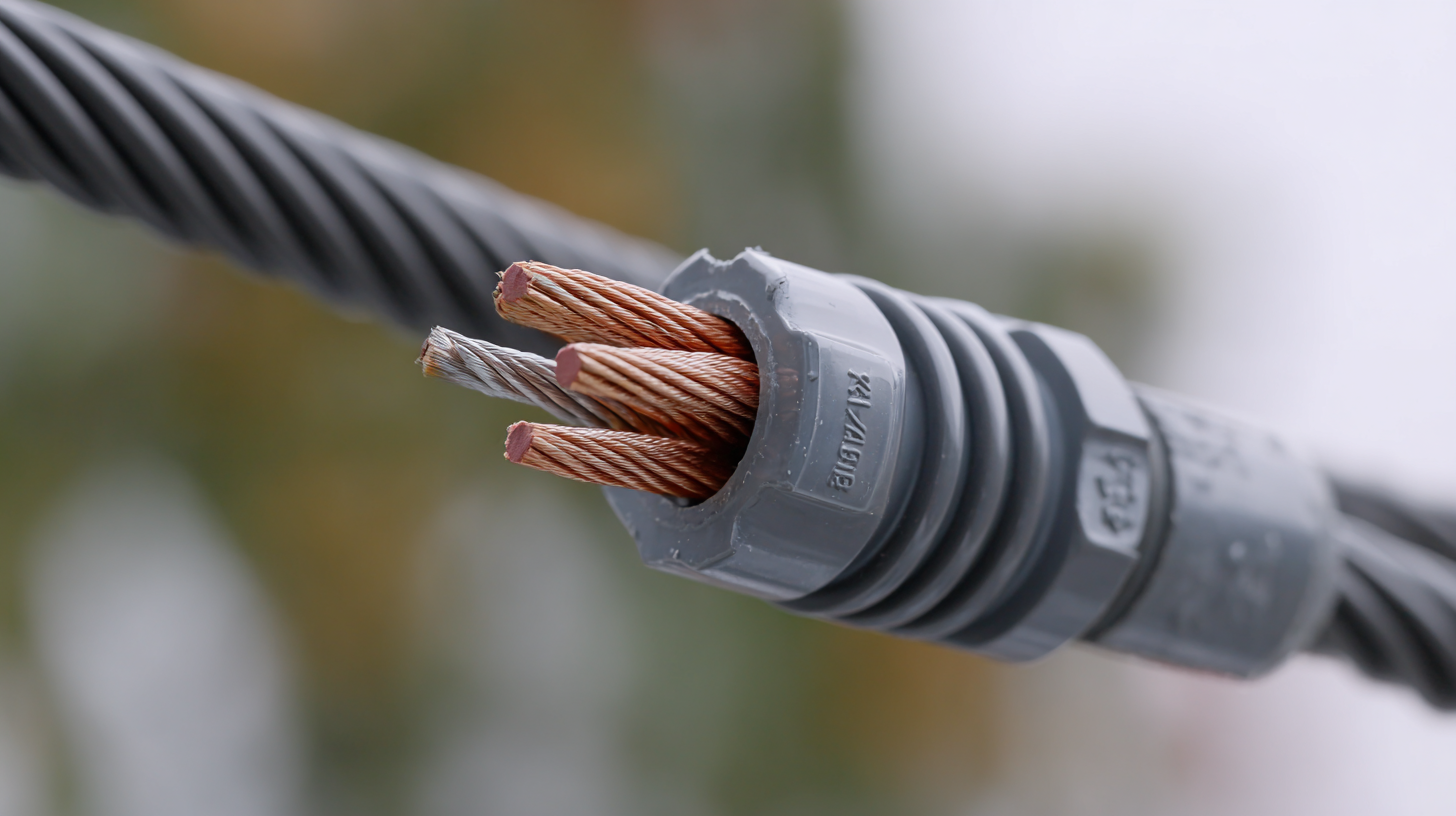

The utilization of Xlpe Insulated Power Cable in electrical projects has become increasingly important due to its unique advantages and superior performance characteristics. According to a recent report by the International Electrotechnical Commission (IEC), the demand for XLPE cables has surged by over 15% in the last five years, driven by their enhanced thermal resistance and superior insulating properties. As industries strive towards greater efficiency and sustainability, Xlpe Insulated Power Cables have emerged as a critical component in modern electrical infrastructure, making a significant contribution to reducing energy losses.

Dr. Emily Thompson, a leading expert in cable technology and a consultant for the Energy and Utilities sector, emphasizes the importance of choosing the right cable for electrical projects. She states, "The adaptability and durability of Xlpe Insulated Power Cable play a vital role in ensuring long-term reliability and safety in power distribution systems." This sentiment echoes a broader industry consensus, underscoring that Xlpe cables not only enhance operational efficiency but also comply with stringent environmental standards, making them the preferred choice for engineers and project managers alike. As we delve into the top benefits of Xlpe Insulated Power Cable, it becomes evident that its integration into electrical projects is not just beneficial; it is essential for meeting today’s energy demands.

In recent years, the emphasis on renewable energy and sustainable practices has significantly influenced the market for electrical projects, highlighting the advantages of XLPE insulated power cables in high-voltage applications.

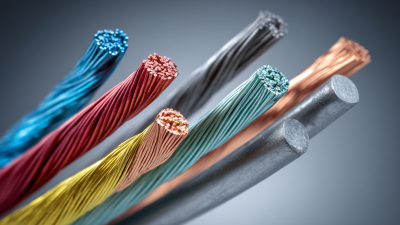

XLPE, or cross-linked polyethylene, provides superior thermal, electrical, and mechanical properties, making it an ideal choice for medium and high-voltage systems. As the demand for renewable energy sources like solar, wind, and hydro grows, the use of XLPE cables ensures efficient energy transmission, crucial for minimizing losses and enhancing overall system reliability.

XLPE, or cross-linked polyethylene, provides superior thermal, electrical, and mechanical properties, making it an ideal choice for medium and high-voltage systems. As the demand for renewable energy sources like solar, wind, and hydro grows, the use of XLPE cables ensures efficient energy transmission, crucial for minimizing losses and enhancing overall system reliability.

Moreover, as innovative solutions emerge in the field of electrical infrastructure, the adaptability of XLPE insulation becomes increasingly pertinent. New advancements, including innovative high-voltage cables developed for electric vehicle architectures and the rise of medium voltage direct current (MVDC) systems, leverage the inherent advantages of XLPE. These advancements support sustainable practices by facilitating more efficient transmission of decarbonized energy, underscoring XLPE's role as a vital component in the transition towards greener energy infrastructures.

Cross-linked polyethylene (XLPE) insulated power cables have increasingly become the preferred choice for electrical projects due to their significant impact on energy efficiency and power loss reduction. According to a report by the International Energy Agency (IEA), improving energy efficiency in electrical systems can lead to reductions in global electricity demand by up to 30% by 2030. XLPE insulation has a lower dielectric loss compared to traditional PVC insulation, which means that less energy is wasted as heat during electrical transmission. This enhanced performance is essential as we transition to more sustainable energy systems, reducing both operational costs and environmental impact.

Tips for contractors: When selecting power cables, consider the long-term benefits of XLPE insulation. Although the initial cost may be higher, the reduction in power losses can lead to significant savings in energy bills. Furthermore, XLPE cables offer better resistance to chemicals and moisture, leading to lower maintenance costs over time.

Another advantage of XLPE insulated cables is their capacity for higher operating temperatures, which enhances energy efficiency. A report by the Electrical Power Research Institute (EPRI) indicates that higher temperature ratings contribute to better load management and fewer failures attributed to overheating. For project managers, this means increased reliability and longer-lasting installations, ultimately boosting overall project efficiency.

XLPE (cross-linked polyethylene) insulated power cables are increasingly popular in electrical projects due to their superior durability and longevity, particularly in harsh conditions. According to the International Copper Association, XLPE cables can withstand higher temperatures and offer better resistance to thermal aging compared to traditional PVC cables. This is largely due to the XLPE insulation's molecular structure, which provides enhanced mechanical and electrical properties, allowing these cables to operate efficiently in environments ranging from extreme heat to sub-zero temperatures.

A study by the Institute of Electrical and Electronics Engineers (IEEE) highlights that XLPE cables can maintain performance under conditions that would typically diminish the lifespan of standard insulated cables. For instance, XLPE cables exhibit outstanding resistance to moisture, chemicals, and UV radiation, making them ideal for outdoor installations or areas exposed to harsh environmental factors. Furthermore, the operational lifespan of these cables can exceed 30 years, significantly reducing the need for replacements and maintenance, thereby delivering substantial cost savings over time. This exceptional durability ensures reliability in electrical projects, contributing to safer and more efficient power distribution systems.

When considering the insulation materials for electrical projects, XLPE (Cross-Linked Polyethylene) insulated power cables stand out against traditional materials like PVC (Polyvinyl Chloride) and PE (Polyethylene) in terms of cost-effectiveness and performance. According to a report by the International Power Cable Association, XLPE cables offer a significant reduction in material costs by approximately 15-20% due to their enhanced thermal resistance and durability, which minimizes the need for replacements and maintenance. This longevity translates to lower lifecycle costs, making XLPE an attractive choice for project managers focused on budget efficiency.

Moreover, a study from the Electrical Insulation Materials Conference indicated that XLPE insulation can withstand higher temperatures—up to 90°C continuously and 250°C during emergencies—compared to conventional options that typically cap at about 70°C. This higher thermal tolerance not only improves safety but also enhances the overall efficiency of power distribution systems. The shift to XLPE can lead to operational savings of around 10-15% in energy costs over time, as the reduction in energy losses contributes directly to a project’s bottom line. As industry standards evolve, embracing XLPE cables may well become the norm, particularly for projects aiming for sustainability and cost management.

The environmental benefits of using XLPE insulated cables are increasingly recognized in the context of sustainable electrical projects. These cables are not only designed to provide exceptional durability and performance but also contribute to the reduction of greenhouse gas emissions. By utilizing advanced cross-linked polyethylene insulation, XLPE cables enable more efficient energy transmission, which is crucial for renewable energy sources like solar, wind, and hydropower. Their superior insulating properties decrease energy losses, ultimately leading to lower carbon footprints for electrical systems.

As the demand for high-performance cables rises, particularly with the growth of the renewable energy sector, the market for cable materials is set to expand significantly. This trend reflects a broader societal shift towards more sustainable practices in energy production and consumption. Technological advancements in the manufacturing of medium voltage cables further enhance their efficiency and longevity, solidifying their role in supporting a more sustainable energy future. With projections suggesting that the wire and cable materials market will see substantial growth by 2035, the emphasis on environmentally friendly solutions will continue to drive innovation and market investments in the coming years.