In the realm of electrical safety, the choice of materials plays a crucial role in ensuring optimal performance and grounding reliability. One standout option is Braided Copper Ground Wire, which boasts unparalleled conductivity and flexibility compared to traditional grounding methods. According to a recent report by the International Association of Electrical Inspectors, using high-quality braided wires can reduce the risk of electrical faults by up to 40%. This emphasizes the importance of selecting the right grounding solutions for both commercial and residential applications.

Expert electrical engineer, Dr. William Hartman, underscores the significance of this topic by stating, "Utilizing Braided Copper Ground Wire not only enhances safety but also improves long-term performance by minimizing the risk of corrosion and wear." With a myriad of options available in the market, identifying the best Braided Copper Ground Wire can be daunting. However, understanding the various features and benefits can guide consumers to make informed decisions that enhance their electrical safety measures.

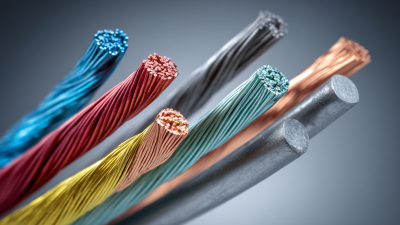

In this article, we will explore the ten best Braided Copper Ground Wire options, focusing on attributes such as durability, conductivity, and design, providing you with an essential guide for superior electrical safety.

When selecting braided copper ground wire for electrical safety, several key features are crucial to consider. The wire's gauge is essential, as it determines the wire's capacity to handle electrical loads. A lower gauge typically indicates a thicker wire, which can support higher currents. According to the National Electrical Code (NEC), grounding wires must meet specific ampacity ratings to ensure safety. For instance, a 6-gauge wire can handle up to 65 amps, making it suitable for various applications, from residential to industrial settings.

Another important aspect is the level of flexibility and durability of the braided copper wire. High-quality braided wires often incorporate a multi-stranded design, enhancing flexibility and resistance to fatigue when subjected to movement or vibration. Reports show that such designs can increase the lifespan of grounding systems by over 30%, providing added reliability in harsh environments. Additionally, ensures that the wire features superior corrosion resistance, as copper can oxidize over time, potentially reducing its conductivity. Selecting options with protective coatings or treated finishes can significantly improve performance and longevity, making them worthwhile investments for ensuring electrical safety.

| Option | Wire Gauge | Length | Strands | Rated Amperage | Resistance |

|---|---|---|---|---|---|

| Option 1 | 10 AWG | 25 ft | 7 | 30 A | 0.001 Ohm/ft |

| Option 2 | 8 AWG | 50 ft | 19 | 40 A | 0.00064 Ohm/ft |

| Option 3 | 6 AWG | 100 ft | 37 | 55 A | 0.0004 Ohm/ft |

| Option 4 | 4 AWG | 75 ft | 19 | 70 A | 0.00025 Ohm/ft |

| Option 5 | 2 AWG | 200 ft | 61 | 95 A | 0.0001 Ohm/ft |

| Option 6 | 3 AWG | 150 ft | 26 | 85 A | 0.00012 Ohm/ft |

| Option 7 | 1 AWG | 300 ft | 127 | 120 A | 0.00008 Ohm/ft |

| Option 8 | 6 AWG | 50 ft | 19 | 55 A | 0.0004 Ohm/ft |

| Option 9 | 8 AWG | 80 ft | 19 | 40 A | 0.00064 Ohm/ft |

| Option 10 | 10 AWG | 60 ft | 7 | 30 A | 0.001 Ohm/ft |

When it comes to ensuring superior electrical safety, choosing the right braided copper ground wire is essential. This comparison highlights some of the best options available on the market, focusing on their unique features and performance. High-quality braided copper wires are designed to provide excellent conductivity and flexibility, making them ideal for various electrical applications, including grounding systems and industrial equipment.

Among the top contenders are wires that boast a high strand count, which enhances flexibility while reducing resistance. Some products offer additional benefits like corrosion resistance and increased durability, ensuring long-lasting performance even in harsh environments. Additionally, the gauge of the wire plays a crucial role; lower gauge numbers indicate thicker wires that can handle higher current loads, making them safer for demanding electrical systems. By comparing these factors, users can make informed decisions that best suit their electrical safety needs.

When it comes to ensuring electrical safety, the installation of braided copper ground wire plays a crucial role. To maximize safety, it’s essential to follow proper installation techniques. One important tip is to ensure that the ground wire is securely connected to the grounding electrode system. This connection must be tight and free of corrosion, as a poor connection can lead to potential electrical hazards.

Another critical aspect is the routing of the ground wire. It should be installed in a manner that minimizes exposure to physical damage and environmental factors. Using conduit for outdoor installations can protect the wire from moisture and mechanical stress. Additionally, always check local codes and regulations to ensure compliance, as these guidelines are designed to enhance safety standards.

Regular inspections also contribute significantly to electrical safety. Periodically check the ground wire for any signs of wear or damage. Replace any compromised sections immediately to prevent potential failures. A well-maintained ground system not only protects equipment but also safeguards people from electrical shock hazards.

To ensure the longevity and reliability of copper ground wire, regular maintenance and best practices are essential. One critical measure is to inspect the connections periodically for signs of corrosion or wear. Corrosion can significantly reduce the effectiveness of grounding systems, so addressing any issues promptly helps maintain optimal electrical safety. Additionally, ensuring that the connections are tight and secure can prevent issues caused by electrical resistance, which may lead to overheating.

Another vital aspect of maintenance involves keeping the ground wire clean and free from debris. Dirt, moisture, and environmental contaminants can affect conductivity, so wiping down the wire and ensuring it remains free from obstructions can improve performance. Furthermore, environmental factors should be considered; using protective coatings or conduits can shield the wire from harsh weather and extend its lifespan. By following these best practices, the effectiveness and durability of braided copper ground wire can be enhanced, ensuring ongoing safety in electrical systems.

Braided copper ground wire is widely recognized for its exceptional conductivity and flexibility, making it an ideal choice for various electrical applications. One common application is in grounding systems, where it effectively connects electrical equipment to the earth to prevent electrical shock and equipment damage. The multiple strands of copper in braided wire enhance its surface area, allowing for improved current flow and minimized resistance. This results in a more efficient grounding system, which is crucial for safety in residential, commercial, and industrial setups.

Another significant benefit of braided copper ground wire is its durability and resistance to corrosion. This makes it suitable for outdoor installations and areas subjected to harsh environmental conditions. Additionally, the braid design allows for easy installation, as it can be bent and shaped to fit specific applications without compromising its integrity. This versatility is highly valued in electrical construction and maintenance, ensuring that the grounding connections maintain their effectiveness over time. Consequently, opting for braided copper ground wire not only enhances electrical safety but also prolongs the lifespan of electrical systems.