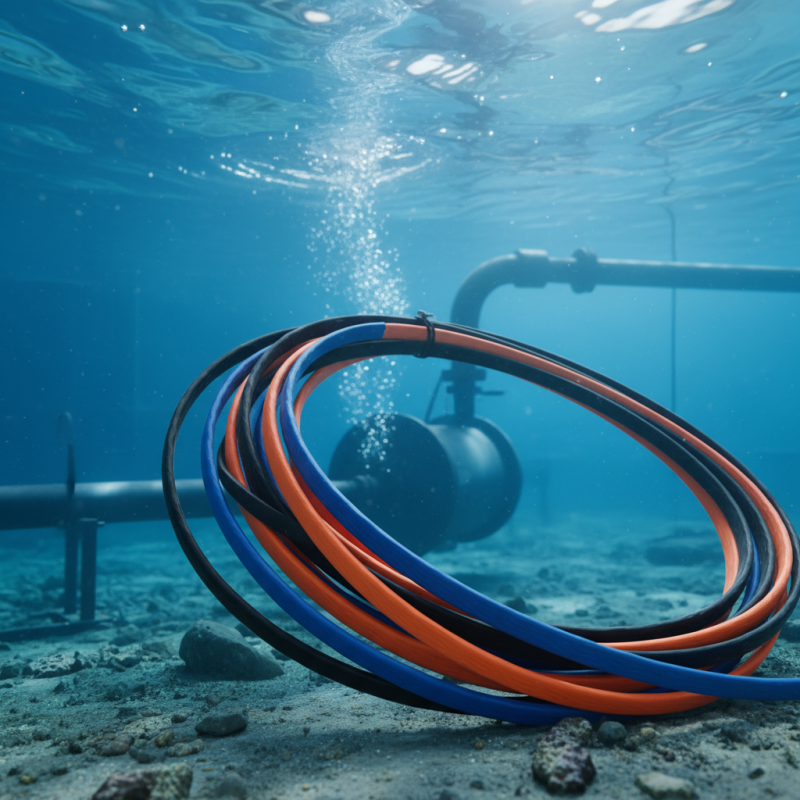

In today's industrial landscape, the demand for reliable electrical solutions is growing. Flat Submersible Cables are key components in various applications, from water treatment to agriculture. According to recent industry reports, the global market for submersible cables is projected to expand by 7% annually, highlighting their significance.

These cables must withstand harsh environments. They play vital roles in powering submersible pumps and underwater equipment. Trends indicate a preference for flat designs due to their flexibility and ease of installation. However, selecting the right flat submersible cable is not straightforward.

Quality often varies widely among manufacturers. Some may not meet the rigorous safety and performance standards required for submersible operations. Investing in high-quality cables can mitigate risks. Nonetheless, the importance of thorough research cannot be overstated. Users should weigh options carefully to avoid costly errors.

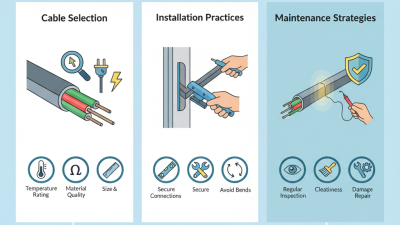

When choosing flat submersible cables, several key features stand out. First, flexibility is essential. These cables often need to navigate tight spaces. A more flexible cable will perform better in those conditions. Thickness matters too; a thinner cable may be easier to install but might sacrifice durability.

Another important aspect is the insulation material. High-quality insulation protects against water and chemicals. It also promotes longevity, especially in harsh environments. Consider the temperature range as well; cables must withstand extreme conditions.

Lastly, check the cable's voltage rating. Each application demands different voltage levels. A mismatch can lead to failures or accidents. While some cables might seem sufficient, their true capabilities might fall short. Evaluate them carefully against your specific needs. Remember, the right choice can make a significant difference in performance and safety.

This chart represents various criteria for evaluating the best flat submersible cables in 2026. Each criterion is rated from 1 to 10, highlighting key features of the cables such as material quality, water resistance, temperature range, flexibility, and cost efficiency.

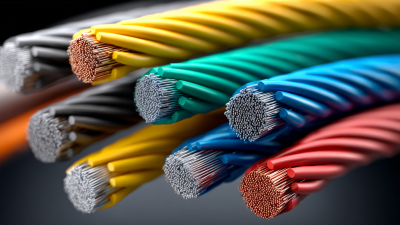

Flat submersible cables are essential in various applications, particularly in water pumping, irrigation, and dewatering processes. The construction of these cables primarily involves materials that ensure durability and resistance to harsh environmental conditions. Two common materials used are polyvinyl chloride (PVC) and thermoplastic elastomers (TPE). PVC provides excellent insulation and is often used for its cost-effectiveness. But, it may not withstand extreme temperatures as well as TPE.

Another vital component is the conductor material. Copper is the standard choice due to its excellent conductivity. However, aluminum is gaining traction because it is lighter and more affordable. In some applications, for reduced weight, a combination of materials is used. Surprisingly, engineers sometimes overlook the effect of moisture on cable performance. It’s crucial to consider water ingress protection for maximizing lifespan.

Tips: When selecting a cable, always check the insulation rating. It affects performance in wet conditions. Additionally, consider the cable's flexibility. A flexible cable is easier to install in tight spaces. As technology advances, it's observable that some new materials are being tested, such as bio-based polymers. However, their long-term efficiency and performance in submersible conditions are still subjects for further investigation.

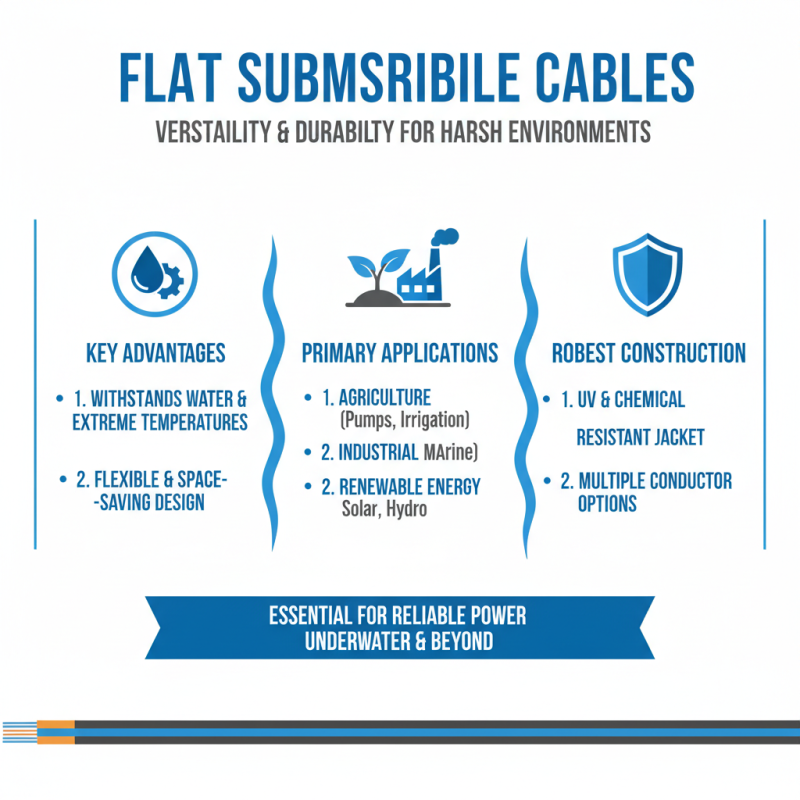

Flat submersible cables are essential in various industries. They offer versatility in applications ranging from agriculture to industrial settings. These cables are designed to withstand harsh conditions, including water exposure and extreme temperatures.

In agriculture, flat submersible cables power submersible pumps. These pumps are crucial for irrigation systems. They help transport water from deep wells to the surface, ensuring crops receive sufficient hydration. In industrial environments, these cables are used in wastewater management. They connect pumps and sensors, facilitating the control of water treatment processes.

However, it’s important to consider potential limitations. Installation might require additional care to avoid damage. Incorrect installation can lead to costly repairs. Also, the environment where these cables operate can affect their longevity. Choosing the right cable for the specific application is vital for optimal performance.

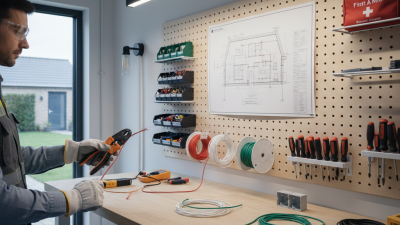

In 2026, flat submersible cables are gaining traction across various applications. The market has numerous options, each with distinct features. It’s essential to compare different brands to identify what suits your needs best. Look for cables that offer flexibility, durability, and resistance to harsh environments. These factors can significantly affect performance and longevity.

Brand A might excel in offering high waterproof ratings. Meanwhile, Brand B could provide superior flexibility for tight installation spaces. Brand C often focuses on environmentally friendly materials. However, some may struggle with consistency in production quality. Not every cable performs reliably, making extensive reviews essential for informed decisions.

When choosing a flat submersible cable, consider the specific application. What works for one scenario may not fit another. Research is crucial, but real-world feedback also helps. Each brand has strengths and weaknesses. Identifying these can save time and resources. There's a lot to evaluate, and the choice can sometimes feel overwhelming.

Flat submersible cables are essential for various applications, including pump systems and underwater projects. To ensure their longevity, proper maintenance is crucial. Regular inspections can identify wear and tear. Check for any cracks or fraying in the cables. Look for any signs of moisture intrusion, which can cause significant damage.

Cleaning is another important task. Use a damp cloth to wipe the cables and remove any debris. Accumulated dirt can lead to corrosion over time. Ensure the cable connections are secure. Loose connections can create hotspots and affect performance.

Proper storage also matters. Store cables in a cool, dry place when not in use. Avoid bending or twisting them excessively. Such actions can weaken the cable structure. Sometimes, we overlook small details, but they are critical for preventing larger issues. Regular maintenance efforts can save money and extend the life of your flat submersible cables.