In the realm of electrical projects, the choice of materials plays a critical role. Among these, Flexible Cable Wire stands out for its versatility and adaptability. According to a recent report by the Global Wire Industry Association, the demand for flexible cables is expected to grow by 7.5% annually over the next five years. This growth reflects the increasing reliance on flexible wiring in various applications, from residential wiring to automotive systems.

Expert John Smith, a leading figure in the flexible cable sector, emphasizes, "Flexible Cable Wire is crucial for modern electrical systems. It provides the adaptability needed for intricate installations." Yet, selecting the right type of flexible cable wire can be challenging. Many projects fail to account for specific requirements like temperature, flexibility, and current rating. Understanding these factors is key to avoiding potential pitfalls and ensuring project success.

As technology evolves, the landscape of electrical wiring continuously changes. What worked yesterday may not be suitable today. Therefore, it's essential to stay informed about the latest advancements in flexible cable wires. This awareness directly impacts project outcomes, highlighting the importance of knowledgeable selections in our ever-evolving industry.

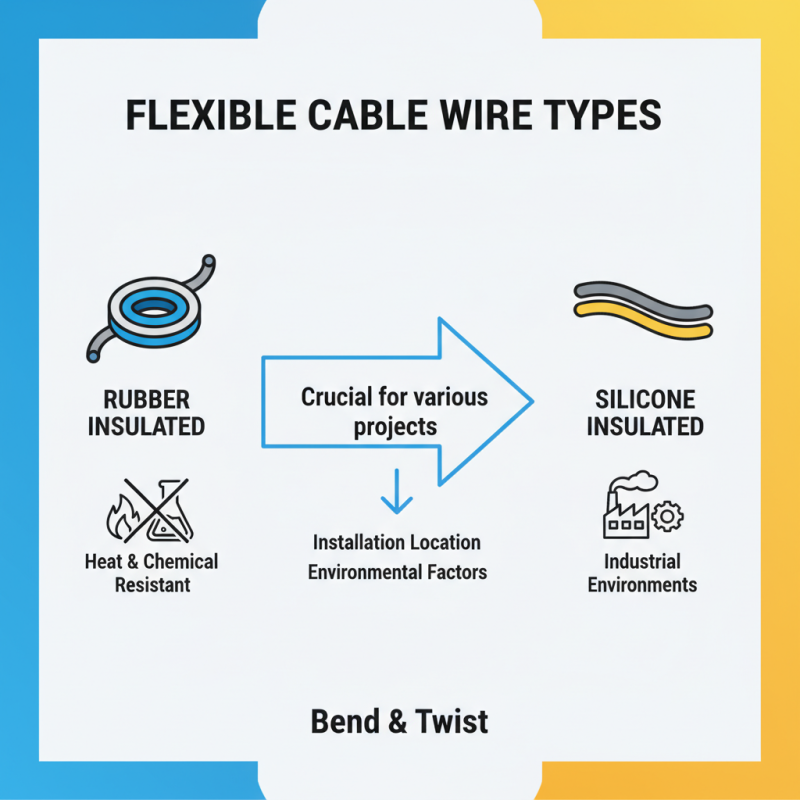

When it comes to electrical applications, understanding flexible cable wire types is crucial. These cables are designed to bend and twist, making them ideal for various projects. For instance, rubber or silicone-insulated wires offer excellent flexibility and durability. They stand up well against heat and chemicals, a significant plus for industrial environments. The choice often hinges on your specific needs, such as the installation location and environmental factors.

Another popular type is stranded wire. Unlike solid wire, stranded wire consists of multiple small strands, giving it superior flexibility. This feature allows for easy routing in tight spaces, making it suitable for complex installations. However, using stranded wire can pose challenges in connectors. Often, the strands may fray or break, leading to potential issues. It’s vital to handle these wires with care.

Ultimately, selecting the right flexible cable wire involves careful consideration. Observing how different types perform in various scenarios can be enlightening. While many assume one type fits all, the truth is far more complex. Each application requires specific attributes, reminding us that no single solution is perfect.

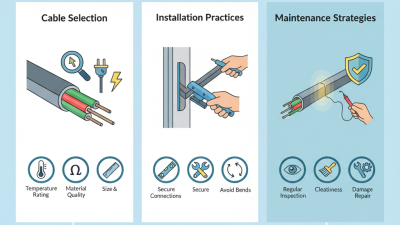

When selecting flexible cables for electrical projects, several factors come into play. Wire gauge is crucial. Thicker wires can carry more current but are less flexible. Consider the insulation material too. PVC offers durability while rubber provides extra flexibility.

Temperature ratings matter as well. Some cables work better in extreme heat or cold. Choosing the wrong one can lead to failures. Think about the cable's environment. Is it exposed to moisture? If so, moisture-resistant options are essential.

Also, remember to weigh cost versus quality. A cheaper cable might not last. Check the flexibility; not all cables bend easily. Reflect on your project’s specifications. Details like length and movement can affect your choice significantly. Don’t rush this decision; it can impact safety and performance.

This chart illustrates the flexibility ratings of various types of flexible cables used in electrical projects. Each cable type is rated on a scale from 1 to 10, indicating its flexibility, which is an essential factor to consider when selecting cables for specific applications.

When planning electrical projects, knowing the right flexible cable wire types can save time and money. Flexible cables are essential for various applications, from home wiring to industrial uses. According to the National Electrical Manufacturers Association (NEMA), demand for flexible wiring has surged by about 15% annually. This demand reflects growth in construction projects and a shift towards more complex electrical systems.

Commonly used types include PVC insulated wires and rubber insulated cables. PVC insulated wires are often preferred for indoor wiring. They are both lightweight and resistant to moisture. On the other hand, rubber insulated cables excel in outdoor conditions. They can withstand harsh environments and resist abrasions. Industry reports suggest that rubber insulated wires have a longer lifespan, which can reduce replacement frequency.

However, choosing the right type isn't always straightforward. Users may struggle with compatibility issues between different wire types and connectors. This is particularly concerning in complex setups. Moreover, not all installers are aware of the specific requirements for flexible wiring. Understanding the differences is crucial for safety and performance. Without proper knowledge, projects can face significant risks, leading to increased costs down the line.

Flexible cables are essential for various electrical projects. They are widely used in residential, commercial, and industrial applications. Each type of flexible cable has unique benefits that can enhance your project. For instance, silicone rubber cables are heat resistant and ideal for high-temperature environments. Their flexibility also allows for easy installation in tight spaces.

Another popular type is PVC insulated cables. They are highly durable and resistant to moisture and chemicals. This makes them perfect for outdoor use or in harsh conditions. On the other hand, polyurethane cables offer exceptional abrasion resistance. They are often used in robotics and industrial machinery.

The choice of cable can significantly affect the performance of your project. Some may find it challenging to determine the best option. It's crucial to assess your specific needs before making a selection. The right flexible cable can improve safety and efficiency. However, skimping on quality can lead to serious issues later. A reflective approach on the cable type is important.

| Wire Type | Applications | Benefits | Conductor Material |

|---|---|---|---|

| PVC Flexible Cable | General purpose wiring, indoor use | Good flexibility, resistance to moisture | Copper |

| Silicon Rubber Cable | High-temperature applications, ovens | High heat resistance, flexible in low temperatures | Copper |

| Rubber Flexible Cable | Heavy machinery, outdoor use | Durable, weather-resistant, good flexibility | Copper |

| Foil Shielded Cable | High-frequency applications, data transmission | Reduces electromagnetic interference | Copper |

| Braided Wire | Electronics, robotics | Excellent flexibility and strength | Aluminum or Copper |

| Tinsel Wire | Audio cables, headsets | Very flexible, low dielectric loss | Copper |

| Flat Ribbon Cable | Data connections, computer hardware | Space-saving design, easy to route | Copper |

| Auto Wire Cable | Automotive applications | Resistant to oil and heat, good flexibility | Copper |

| High-Flex Cable | Robotic applications, conveyors | Designed for continuous bending, very durable | Copper |

| Instrumentation Cable | Control systems, monitoring | Stable signal transmission, versatile | Copper |

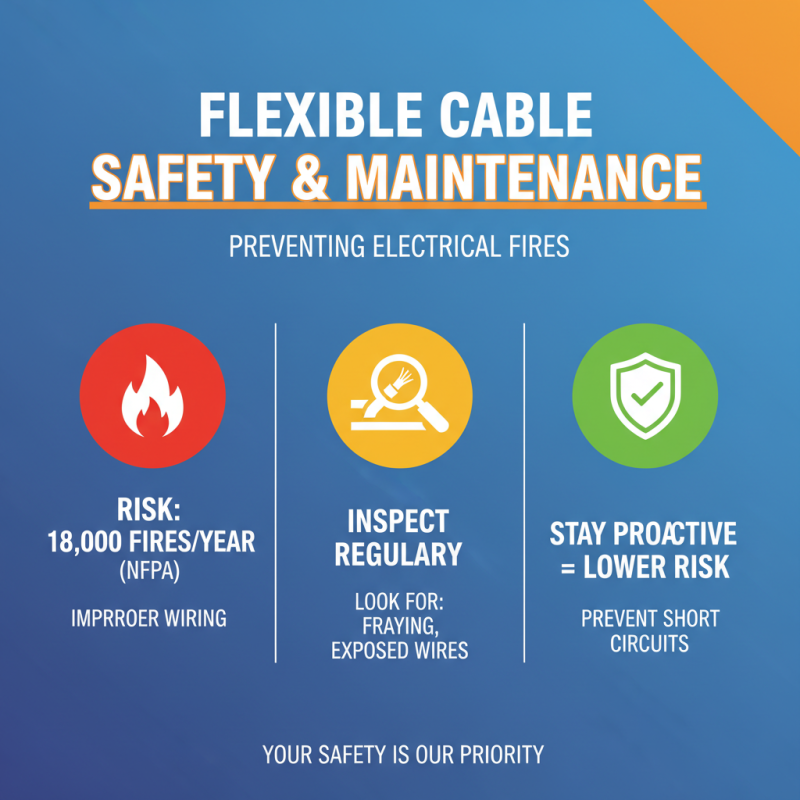

When using flexible electrical cables, safety and maintenance are crucial. According to the National Fire Protection Association (NFPA), improper wiring causes about 18,000 structure fires annually. To prevent these disasters, inspect cables regularly. Look for signs of wear, such as fraying or exposed wires. Damaged cables can lead to short circuits. Staying proactive lowers risks.

Proper storage is also vital. Avoid bending or twisting cables excessively. This can damage the internal structure, leading to failure. Keep cables dry and store them in a cool place. Humidity can compromise insulation materials, making them less effective over time. The Electrical Safety Foundation International (ESFI) reports that damaged insulation is a common cause of electrical accidents.

Using the right connectors is equally important. Mismatched connectors can cause overheating. Ensure compatibility to maintain safety. Remember, maintenance goes beyond just physical checks. Regularly assess your installation environment. Dust and moisture collection can affect performance. Taking these steps helps enhance longevity while ensuring safety.