Choosing the right welding cable is crucial for ensuring safety, efficiency, and the overall success of your welding projects. According to the American Welding Society (AWS), the selection of appropriate welding materials, including cables, can significantly affect the quality of the weld produced. With the welding industry projected to reach a market value of over $27 billion by 2025, understanding the technical specifications and requirements of welding cables becomes essential for both seasoned professionals and DIY enthusiasts alike.

Welding cables carry electrical current to welding equipment, and their quality can impact not just the performance of the welding process, but also the safety of the workspace. Inadequate or incorrect cables can lead to equipment failure, increased heat generation, and potential hazards to the operator. Industry studies indicate that using high-quality welding cables can improve operational efficiency and reduce long-term maintenance costs, making it critical for users to understand how to select the best options for their specific needs and projects.

As the demand for diverse welding applications grows, so does the importance of choosing the right welding cable. From understanding the differences between copper and aluminum cables to recognizing the importance of ampacity and insulation types, making an informed decision on welding cables is essential in avoiding common pitfalls and enhancing the overall welding experience.

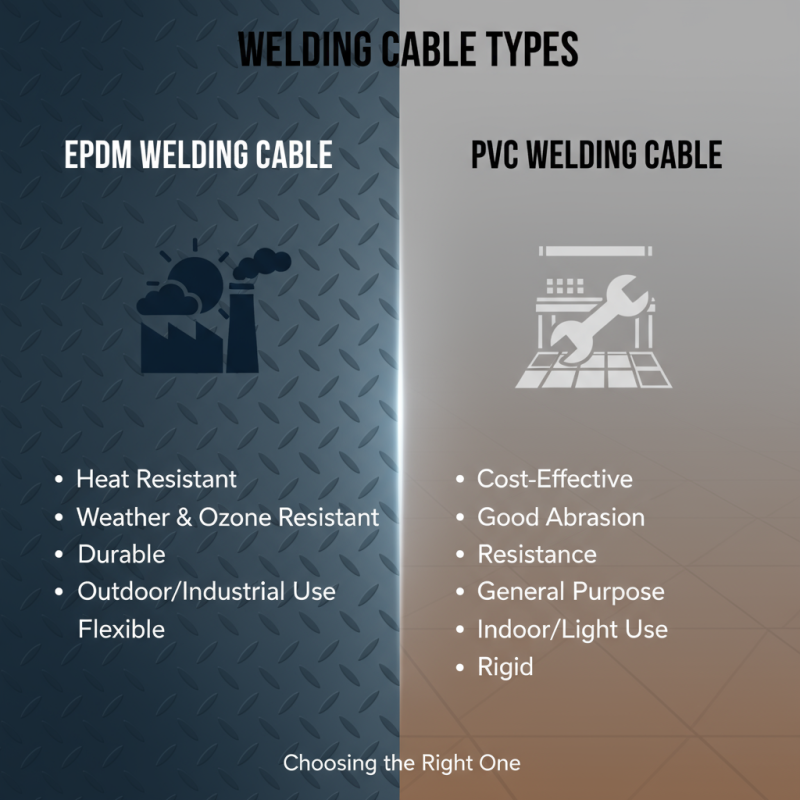

When selecting the right welding cable, it's essential to understand the different types available and their respective applications. Welding cables typically come in two standard types: EPDM (Ethylene Propylene Diene Monomer) and PVC (Polyvinyl Chloride). EPDM cables are highly resistant to heat, weather, and ozone, making them ideal for outdoor or industrial environments where durability is crucial. These cables are often flexible, allowing for ease of movement and handling during welding tasks.

On the other hand, PVC cables are more economical and are commonly used in lighter-duty applications. While they provide good electrical insulation, they may not withstand extreme temperatures or harsh environmental conditions as effectively as EPDM cables. Additionally, within these types, you may find variations in the gauge of wire, which affects the cable's current-carrying capacity. It's important to match the wire gauge to your welding machine's requirements to ensure optimal performance and safety during your projects. Understanding these distinctions will help you select the best welding cable tailored to your specific needs.

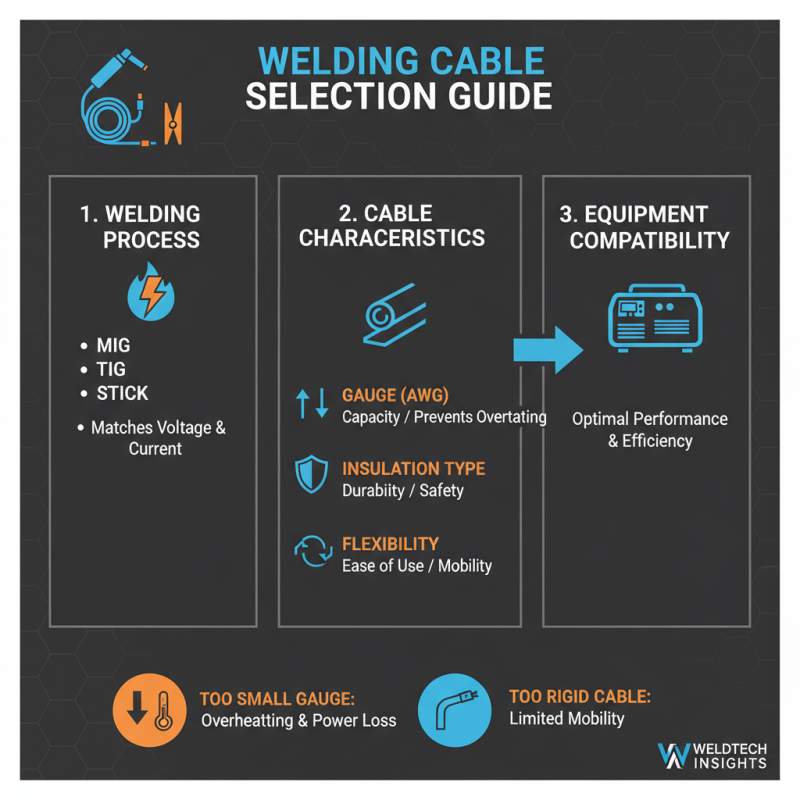

When selecting welding cables, several key factors should be taken into account to ensure that you choose the best option for your needs and projects. First, consider the cable’s size or gauge, which is determined by the amount of current it will carry. A thicker cable can handle higher amperages, while a thinner cable may be sufficient for lighter tasks. Always match the cable gauge with the requirements of your welding machine and the type of work you’re undertaking.

Tips: Always check the specifications of both your welder and the welding cables to find a compatible size. It’s also wise to stay a little above the minimum requirement to accommodate any fluctuations in power.

Another crucial factor is the insulation material of the welding cable. Look for cables with durable insulation that can withstand heat and abrasion, as welding processes can generate high temperatures. Rubber and PVC are common materials used for insulation, but rubber typically offers better flexibility and durability, making it suitable for heavy-duty applications.

Tips: If you frequently work in challenging environments, consider investing in cables with additional protective features. This will enhance longevity and ensure safe operation over time. Additionally, pay attention to the cable length; longer cables can lead to voltage drop, which affects performance.

When selecting welding cables, one of the most critical factors to consider is their electrical rating and capacity. The electrical rating of a welding cable, typically measured in amperes (A), determines how much current the cable can safely carry without overheating. Industry standards suggest using cables that can handle at least 25% more current than what the welding machine outputs to ensure reliability and avoid potential failures. For instance, a welding machine rated for 200A would benefit from a cable rated for 250A or higher. According to the American Welding Society (AWS), proper cable choice can significantly reduce energy loss and improve overall welding efficiency.

Tips for evaluating the appropriate cable for your projects include checking the insulation type, diameter, and flexibility. Cables with higher flexibility ratings are easier to maneuver in tight spaces, while those with robust insulation provide better protection against environmental factors. Additionally, pay attention to the cable length, as longer runs can result in voltage drop, negatively impacting the welding performance. According to the National Electrical Code (NEC), for optimum performance, a cable length of less than 100 feet is recommended for high amperage applications.

Another crucial aspect is the duty cycle of the welding process, defined as the percentage of time a welder can operate within a designated time frame. For instance, a welding machine with a duty cycle of 60% at 200A means you can use it for 6 minutes out of every 10 before it needs to cool down. Ensure that the cable you select can accommodate these operational demands without exceeding its rated capacity. By aligning the cable specifications with the welding machine's characteristics, you can enhance safety and deliver high-quality results on your welding projects.

When selecting welding cables for your projects, assessing the insulation and outer jacket materials is crucial for ensuring durability and safety. Different insulation materials provide various benefits, with thermoplastic and thermoset being the most common choices. Thermoplastic insulation is flexible and resistant to chemicals, making it suitable for environments where mobility is essential. On the other hand, thermoset insulation achieves greater heat resistance and can withstand harsh conditions, making it ideal for high-temperature applications. Evaluating the specific requirements of your welding project helps determine which type of insulation best fits your needs.

Additionally, the outer jacket of the welding cable plays a significant role in protecting the internal components from wear, tear, and environmental factors. Materials such as rubber and neoprene offer excellent resistance to abrasion, UV light, and moisture, thereby extending the life of the cable. For tasks taking place in outdoor settings or where cables may face exposure to various elements, it is imperative to choose jackets that can withstand these conditions. Thoroughly understanding the properties of insulation and outer jacket materials will help you make an informed choice, ensuring that your welding cables can perform effectively and safely throughout their intended use.

| Cable Type | Wire Gauge | Insulation Material | Outer Jacket Material | Temperature Rating (°C) | Durability Rating |

|---|---|---|---|---|---|

| Welding Cable | 2 AWG | EPDM | PVC | 90 | High |

| TIG Welding Cable | 4 AWG | Silicone | Rubber | 100 | Medium |

| MIG Welding Cable | 6 AWG | Neoprene | PVC | 80 | Low |

| Marine Welding Cable | 8 AWG | Hypalon | PVC | 85 | High |

When selecting a welding cable, it is crucial to consider its compatibility with your specific welding equipment. Different welding processes—such as MIG, TIG, and stick welding—require different voltages and current levels, which can significantly influence the type of cable you need. The cable's gauge, insulation type, and flexibility should match the operational demands of your welder to ensure optimal performance. For instance, using a cable that is too small in gauge can lead to overheating and energy loss, while one that is excessively rigid may limit mobility and hinder your workflow.

Moreover, the insulation material of the welding cable plays a vital role in its compatibility with your equipment. High-temperature resistance and abrasion protection are essential, particularly in environments where cables may come into contact with sparks or hot metal. Additionally, the length of the cable can affect the efficiency of your welding task; longer cables may cause voltage drop, leading to inconsistent performance. Ensuring that the cable you choose is not only appropriate in size but also compatible with the environmental conditions of your projects can greatly enhance your welding efficiency and safety.