When it comes to electrical projects, selecting the appropriate materials can significantly impact performance and durability. Among these materials, XLPE cable insulation stands out as a favored choice for many engineers and contractors. Cross-linked polyethylene, or XLPE, offers a range of advantages, including excellent thermal and electrical properties, high resistance to environmental stress, and exceptional durability. These characteristics make XLPE cable insulation suitable for various applications, from residential wiring to industrial power distribution.

However, with numerous options available in the market, choosing the right XLPE cable insulation for your specific project can be challenging. Factors such as operating conditions, installation environment, voltage requirements, and regulatory standards must be carefully considered. Understanding the composition and characteristics of XLPE insulation will enable you to make an informed decision, ensuring optimal performance and longevity for your electrical systems. In this article, we will explore essential considerations for selecting XLPE cable insulation, equipping you with the knowledge necessary to navigate the complexities of this critical component in electrical engineering.

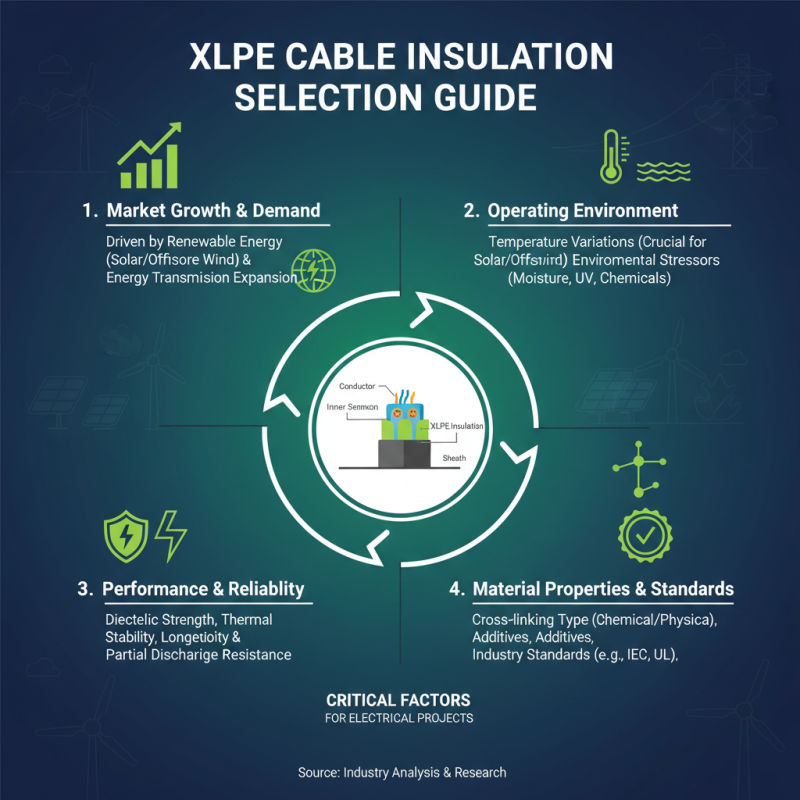

When selecting the right cross-linked polyethylene (XLPE) cable insulation for your electrical projects, there are several critical factors to consider. The projected growth of the XLPE cables market highlights the increasing demand for reliable and efficient insulation materials, driven by advancements in renewable energy initiatives and the escalating need for energy transmission systems. An integral consideration is the operating environment of the cables, which can significantly affect performance. Temperature variations, particularly in solar and offshore wind applications, play a crucial role in determining insulation effectiveness.

Tips for choosing XLPE cable insulation include assessing the cable's temperature rating, as ambient conditions can impact the maximum allowable load. Furthermore, the cable's application—whether for residential, commercial, or industrial use—will inform choices around durability and flexibility. It’s also essential to evaluate the insulation health index through innovative methods, such as machine learning models, which can provide insights into the longevity and reliability of your chosen cables.

The increasing focus on renewable energy is driving innovations in XLPE technology, ensuring not only compliance with industry standards but also contributing to sustainable practices. By carefully considering these factors, you can optimize your project's efficiency and ensure long-lasting performance from your electrical systems.

XLPE (cross-linked polyethylene) insulation has become increasingly popular in electrical projects due to its superior properties, making it a preferred choice among engineers and contractors. Notably, XLPE exhibits excellent thermal stability, allowing it to operate effectively at higher temperatures compared to traditional materials. This characteristic is crucial in minimizing energy losses and enhancing overall efficiency in electrical systems. Additionally, XLPE provides outstanding resistance to moisture and chemicals, ensuring long-term performance even in challenging environments.

As the global demand for XLPE cables rises, the market is projected to grow substantially. From an estimated market size of $35.84 billion in 2024, it is expected to reach $58.66 billion by 2032, with a compound annual growth rate (CAGR) of 6.35%. This growth can be attributed to the increasing adoption of renewable energy sources and smart grid technologies, which require reliable and efficient cable insulation. As such, understanding the properties and benefits of XLPE insulation materials is essential for making informed decisions in electrical project planning and execution.

| Property | Description | Advantages | Applications |

|---|---|---|---|

| Thermal Stability | XLPE can withstand higher temperatures without degradation. | Longevity and reduced risk of failure. | Industrial electrical applications, utility cables. |

| Electrical Insulation | Excellent dielectric properties, reduces current leakage. | Enhanced safety in high voltage environments. | Power distribution systems, communication cables. |

| Chemical Resistance | Resistant to oils, solvents, and various chemicals. | Increased durability in harsh environments. | Agricultural and industrial settings. |

| Moisture Resistance | Low water absorption to prevent insulation breakdown. | Reliability in wet conditions. | Outdoor and underground installations. |

| Flexibility | Good flexibility for ease of installation. | Simplifies complex routing. | Electrical wiring in buildings. |

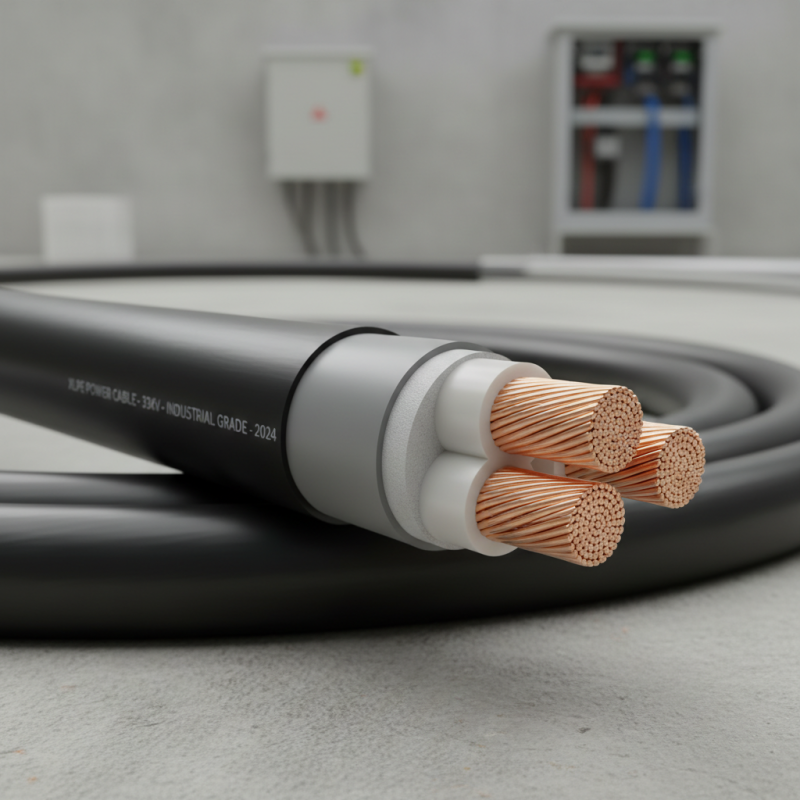

Cross-linked polyethylene (XLPE) cables are increasingly becoming a preferred choice for various electrical projects due to their excellent thermal, electrical, and mechanical properties. The applications of XLPE cables span across several sectors including power distribution, industrial automation, and renewable energy systems. Their resilience against high temperatures and resistance to moisture make them suitable for both underground and overhead installations, significantly enhancing their usability in diverse environments.

The global market for XLPE cables is projected to experience substantial growth, increasing from approximately $35.84 billion in 2024 to an estimated $58.66 billion by 2032. This growth reflects a compound annual growth rate (CAGR) of 6.35%. Such figures demonstrate the rising demand for efficient and reliable insulation materials as industries increasingly focus on modernizing infrastructure and adhering to stringent safety standards. As the market expands, understanding the specific applications and benefits of XLPE cables becomes essential for professionals in the electrical field seeking to make informed decisions for their projects.

When selecting insulation for electrical projects, XLPE (cross-linked polyethylene) stands out for its superior performance compared to other insulating materials. According to a report by Grand View Research, the global XLPE cable market is expected to reach $21.66 billion by 2025, underscoring its growing acceptance in the industry. One of the key advantages of XLPE insulation is its excellent thermal stability, capable of operating at temperatures up to 90°C continuously, and even 130°C intermittently. This makes it a favorable choice for high-voltage applications where reliability is paramount.

In contrast to PVC (polyvinyl chloride) insulation, which is limited to a lower temperature rating of around 70°C, XLPE offers enhanced electrical properties and resistance to moisture and chemicals. A study published by the International Journal of Electrical Power & Energy Systems noted that XLPE cables tend to exhibit lower dielectric losses, leading to improved energy efficiency. Additionally, while rubber insulation provides flexibility, it doesn’t match XLPE's lifespan, particularly in harsh environments. With a lifespan exceeding 40 years, where traditional rubber insulations may only last about 20-30 years, XLPE emerges as a smart, long-term investment for electrical infrastructure projects.

When working with Cross-Linked Polyethylene (XLPE) cables, proper installation and maintenance practices are crucial for ensuring optimal performance and longevity. First, it's essential to verify that the cables are sufficiently rated for the voltage and environmental conditions they will encounter.

During installation, avoid bending the cables beyond their minimum bend radius and ensure that they are correctly anchored to prevent strain at connection points. Using appropriate connectors and terminals can also help maintain the integrity of the cable over time.

Regular maintenance checks are vital for detecting early signs of wear or damage. Inspections should involve looking for abrasions or exposure to excessive moisture and ensuring that cable routing does not put undue stress on the insulation. Also, keeping the cable pathways free of debris and securing the cables away from potential heat sources will enhance their durability. By adhering to these installation and maintenance tips, users can maximize the efficiency and lifespan of XLPE cables in various electrical projects.