Choosing the right Flat Submersible Cable can significantly impact efficiency. Industry expert John Smith once stated, "The right cable makes all the difference in performance and safety." This emphasizes the importance of understanding your exact needs before making a choice.

Flat Submersible Cables come in various sizes and materials. Each type serves a unique purpose in different environments. This can create confusion for consumers. Many may overlook factors like insulation type or temperature ratings. Such details can lead to issues in the long term.

For instance, a cable that is not suited for high temperatures may fail, causing downtime. Cost should not be the only consideration. It is crucial to balance quality and price. Reflecting on priorities can help consumers avoid mistakes. Selecting the right Flat Submersible Cable is not just a task; it’s an investment in reliability.

Flat submersible cables are essential in various applications, especially in water management. These cables are designed to perform under water for submersible pumps and similar devices. Their flat design allows for easy installation in tight spaces. Moreover, they can adapt to challenging environments, making them suitable for wet and harsh conditions.

In residential settings, these cables are often used in wells to power pumps. They ensure a reliable power supply, vital for consistent water delivery. However, the choice of cable is crucial. Not all cables are suitable for every project. Factors like length, depth, and water type affect performance. It’s important to consider these elements carefully.

Some users may overlook the need for insulation ratings. Cables need to withstand not only water but also varying temperatures. A wrong choice can lead to failures and costly repairs. Sometimes, people choose cables based solely on price. This can result in shorts or damage over time. It’s crucial to assess both the functional and environmental needs before making a decision.

| Application | Cable Type | Conductor Material | Voltage Rating | Temperature Range |

|---|---|---|---|---|

| Residential Water Pumps | Flat Submersible | Copper | 600V | -20°C to 60°C |

| Agricultural Irrigation | Flat Submersible | Aluminum | 300V | -10°C to 50°C |

| Industrial Wastewater Management | Flat Submersible | Copper | 600V | -20°C to 70°C |

| Fountain and Pond Pumps | Flat Submersible | Copper | 600V | -20°C to 60°C |

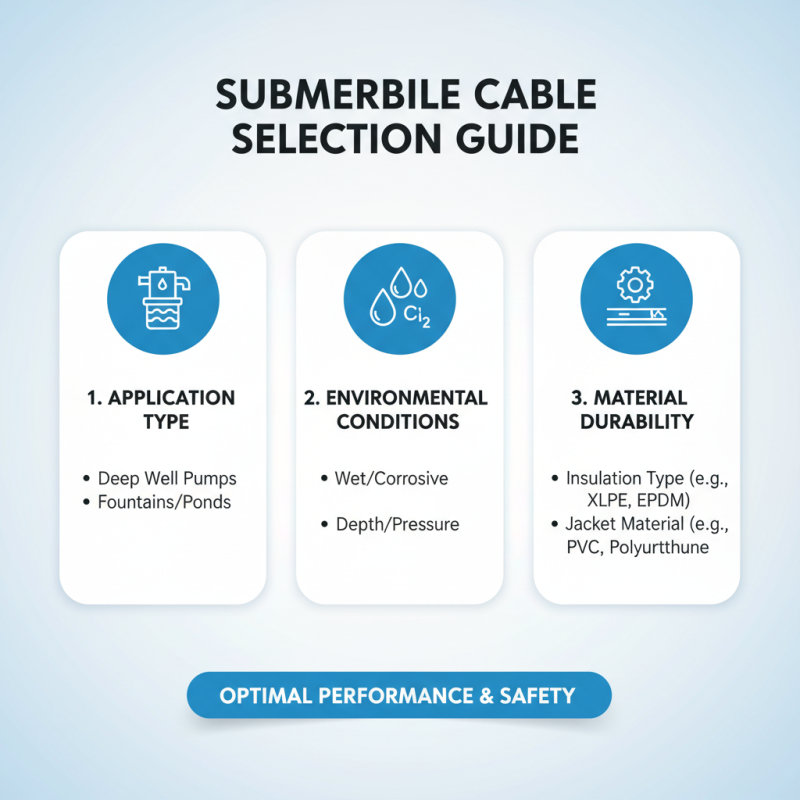

Choosing the right flat submersible cable can be tricky. Several key factors must be considered to ensure optimal performance and safety. The application type is vital. A cable designed for a deep well pump differs from one for a fountain. Understand the specific environment where the cable will be used. Wet and corrosive settings require more durable materials.

One must also pay attention to the cable's voltage rating. Different systems operate at varying voltages. Using the wrong voltage can lead to failure. Additionally, think about the cable's size. A thicker cable can handle more current, but it is heavier and harder to install. Balancing gauge and flexibility is essential.

Don’t forget about insulation. Proper insulation material affects durability and performance. PVC and rubber are common, but they have different resistance to water and heat. It's worth considering how long you expect the cable to last. Make sure to reflect on these details before making a decision. If unsure, consulting with an expert can provide additional insights.

When selecting flat submersible cables, it's crucial to understand their types and specifications. There are generally two categories: PVC insulated cables and rubber insulated cables. PVC cables offer good resistance to moisture and are often cheaper. However, they may struggle in extreme temperatures. On the other hand, rubber insulated cables provide enhanced flexibility and durability. They work well in harsh environments but can be costlier.

Specifications also matter significantly. Voltage rating is one key aspect. Most flat submersible cables have ratings between 300V to 1,000V. Choosing the right voltage is essential to avoid overheating or insulation failure. Additionally, current carrying capacity varies based on the cross-sectional area. For example, a cable with a cross-section of 1.5 mm² can typically handle about 10A. These data points are vital for ensuring efficient operation.

Remember that while selecting cables, the installation environment is crucial. Cables need to be resistant to various factors, like chemical exposure and UV radiation. Not all cables are designed for every condition. Be mindful of these requirements. It's easy to overlook, but this may lead to failures. Engineers often report that miscalculating cable specifications results in system inefficiencies. Always double-check your choices.

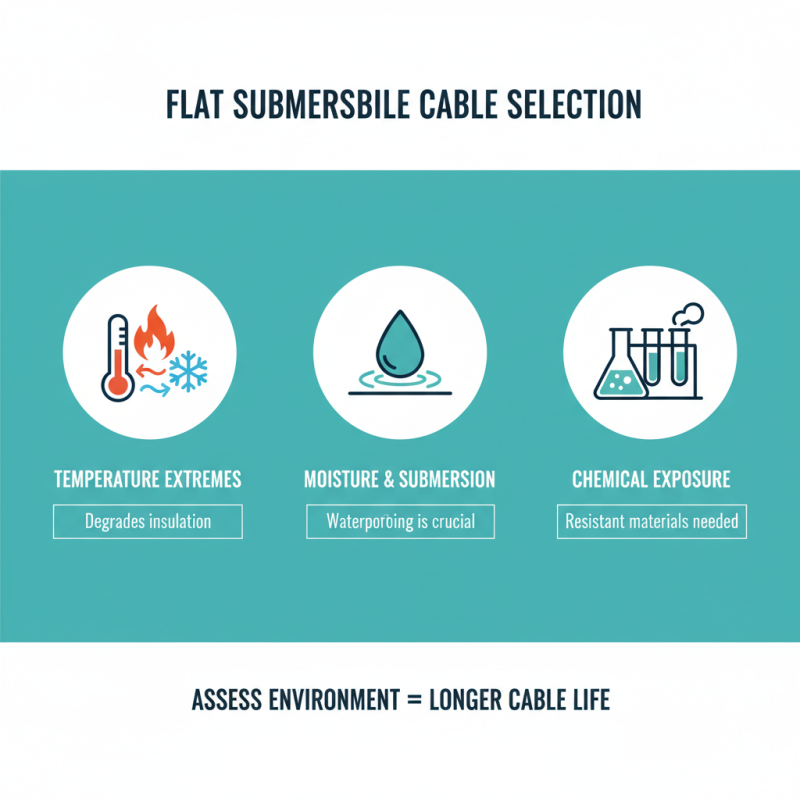

When selecting a flat submersible cable, it's essential to assess the environmental conditions. Understanding these factors can significantly impact performance and longevity. Factors like temperature, moisture, and chemical exposure play a big role in cable selection. For example, extreme temperatures can degrade insulation quickly.

Moisture is another critical condition to consider. Submersible environments can lead to water ingress. This can cause shorts and failures. It's crucial to ensure the cable has adequate sealing and is rated for submersion. Moreover, think about the surrounding chemicals in the environment. Corrosive substances can damage the cable over time.

Even with careful selection, there are always uncertainties. Different conditions may arise unexpectedly. It’s wise to have a backup plan if the initial choice proves inadequate. Regular inspections can help in identifying potential issues early. Aim for a balance between your needs and the environmental challenges. This way, you can enhance reliability and reduce the risk of failures.

When installing flat submersible cables, precision matters. First, ensure the area is dry and free from contaminants. Industry reports indicate that improper handling can reduce cable life by up to 25%. Each cable should have adequate protection against physical damage and electrical exposure. Use cable trays or conduits designed to support the weight and maintain proper alignment.

Regular maintenance is crucial. Inspect cables for signs of wear or corrosion monthly. Inadequate maintenance can lead to unexpected failures. It’s essential to check strain relief connections as they can weaken over time. A study found that about 30% of cable failures result from poor installation practices. Avoid over-tightening connections, which can stress the cable.

Be aware of the environment where cables operate. Submersible cables in harsh conditions may require additional protection. Extreme temperatures can impact performance. Over time, even slight shifts in temperature can affect cable insulation, leading to potential hazards. A detailed log of inspections and repairs can help identify patterns and prevent future issues. Learn from past experiences to improve setup and ensure longevity.