In the ever-evolving world of electrical systems, optimizing performance is a priority for both professionals and enthusiasts alike. According to Dr. Emily Carter, a renowned expert in electrical engineering, "The integration of high-quality components like the Three Core Flat Cable can significantly enhance the reliability and efficiency of any electrical installation." Dr. Carter's research highlights the pivotal role that cabling plays in reducing energy losses and ensuring stable connections in complex systems.

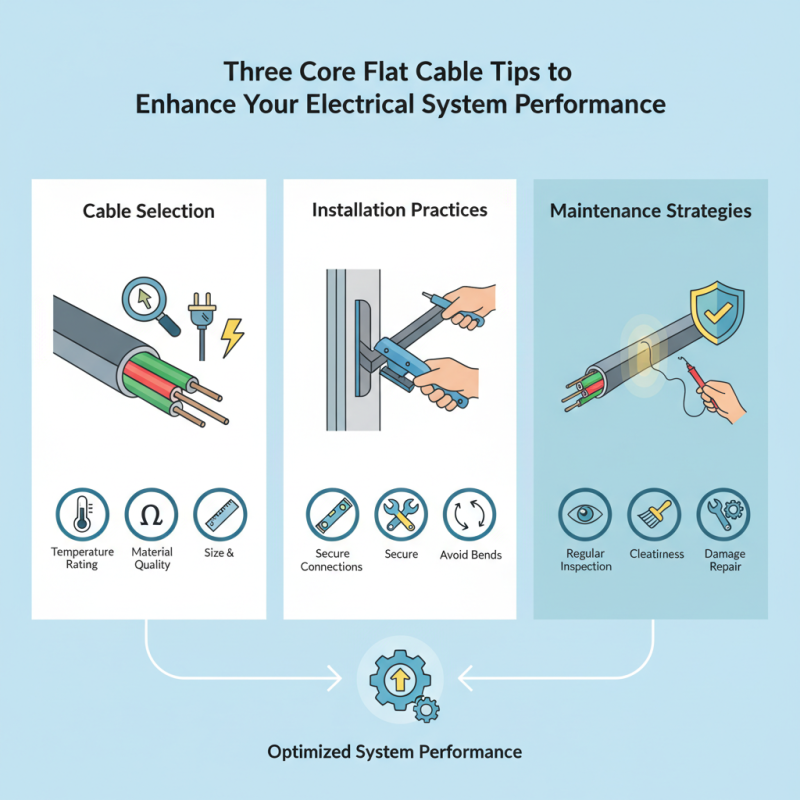

The Three Core Flat Cable, with its design engineered to accommodate various electrical demands, serves as a fundamental component in achieving optimal system performance. This article will delve into three key tips that can help maximize the effectiveness of Three Core Flat Cable installations. By understanding the nuances of cable selection, installation practices, and maintenance strategies, electrical professionals can ensure robust and efficient operations in their projects. As we explore these tips, we will uncover how the thoughtful application of Three Core Flat Cable technology can transform the functionality and longevity of electrical systems.

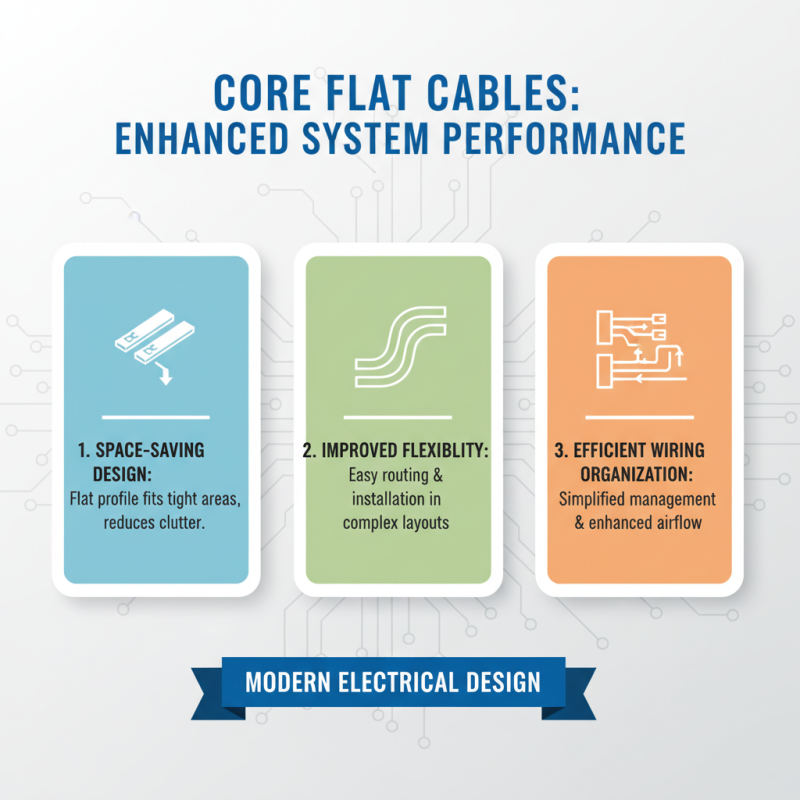

Flat cables are a crucial component in many electrical systems, offering several advantages over traditional round cables. Their design allows for a more compact installation, making them ideal for applications with space constraints. The flat configuration aids in reducing the overall thickness of the wiring harness, which can be particularly beneficial in devices where form factor is vital. Moreover, flat cables can be easier to route in tight spaces, allowing for greater flexibility in design and layout.

Understanding the core basics of flat cables is essential to maximizing their performance in your electrical system. These cables are typically composed of multiple conductors laid flat and typically encapsulated in a flexible insulation layer. This flexibility is not just about ease of installation; it also contributes to enhanced durability against bending and movement, which is crucial in dynamic environments. Furthermore, flat cables can support twisted pair configurations that reduce electromagnetic interference, improving signal integrity and overall system reliability. Knowledge of the varying insulation materials and conductor gauges used in flat cables can empower users to select the most suitable options for their specific applications, ultimately enhancing the performance of their electrical systems.

Core flat cables have rapidly gained popularity in modern electrical design due to their numerous advantages in enhancing system performance. These cables, characterized by their flat profile, provide significant benefits such as space-saving capabilities and improved flexibility. Their design enables efficient organization of wiring, reducing clutter and making installation much simpler. When space is at a premium, core flat cables can fit into tighter spaces than traditional round cables, making them ideal for a variety of applications.

When integrating core flat cables into your electrical system, consider a few essential tips to maximize their performance. First, ensure proper shielding to reduce electromagnetic interference, which can adversely affect signal quality. This is particularly important in environments with many electronic devices. Additionally, pay attention to the cable's current capacity and ensure it is suitable for your specific application to prevent overheating or failure. Lastly, secure cables properly during installation to avoid damage and maintain their integrity over time, which extends their lifespan and ensures consistent performance.

In summary, the advantages of core flat cables in electrical design are clear: they optimize space, enhance flexibility, and can lead to a more organized system. By following these tips, you can harness their full potential, leading to improved efficiency and reliability in your electrical projects.

When selecting the right flat cable for your electrical system, it’s crucial to consider a few key factors that can significantly impact performance. First, assess the current and voltage requirements of your application. Make sure to choose a flat cable that can handle the necessary load without overheating or causing disruptions. Understanding the specifications of your system will guide you in selecting a cable with the appropriate gauge and insulation type.

Another important tip is to evaluate the environment in which the flat cable will be installed. Cables can be affected by factors such as temperature, humidity, and exposure to chemicals. Select flat cables that are designed for specific environmental conditions to ensure longevity and reliability. For instance, if the cable will be used outdoors, opt for materials that offer enhanced protection against UV rays and moisture.

Lastly, don’t underestimate the importance of flexibility and ease of installation. Flat cables are often preferred for tight spaces and intricate designs, but ensure that the chosen cable maintains sufficient flexibility for your application. Consider the mechanical properties as well as the ease with which the cable can be routed through your system, as this will save time and effort during installation.

| Tip | Description | Flat Cable Type | Applications |

|---|---|---|---|

| Choose the Right Material | Select the material based on conductivity and flexibility, considering copper for high performance. | Copper Flat Cable | Industrial machines, power distribution systems |

| Insulation Type Matters | Use insulation materials that are rated for the maximum temperature and environmental conditions of your application. | PVC Insulated Flat Cable | Residential wiring, appliance connections |

| Cable Width and Thickness | Consider cable width and thickness to ensure minimal resistance and max voltage rating is adhered. | Heavy Duty Flat Cable | Construction sites, high load applications |

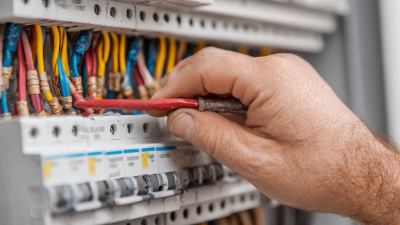

When it comes to enhancing your electrical system performance, the installation of core flat cables is a critical factor that warrants attention. Effective installation practices can drastically reduce noise interference and ensure optimal power delivery. According to a report by the International Electrotechnical Commission, improper installations can lead to a 30% drop in efficiency, underscoring the importance of following best practices.

One key tip for installing core flat cables is to maintain proper spacing between cables during installation. This minimizes the potential for electromagnetic interference (EMI), which can disrupt performance. The National Electrical Manufacturers Association recommends keeping a minimum separation of 12 inches between power and data cables to ensure signal integrity. Additionally, using high-quality connectors and ensuring all connections are secure can prevent voltage drops and enhance overall system reliability.

Another important consideration is the environment where the cables will be installed. According to a study by the Institute of Electrical and Electronics Engineers, temperature and humidity can significantly affect cable performance. It's essential to monitor these factors to prevent degradation. For instance, installing cables in areas with consistent temperature control can maintain their efficiency and prolong their lifespan. Adequate cable management practices, such as avoiding sharp bends and using protective conduits, further contribute to the longevity and effectiveness of core flat cables in any electrical system.

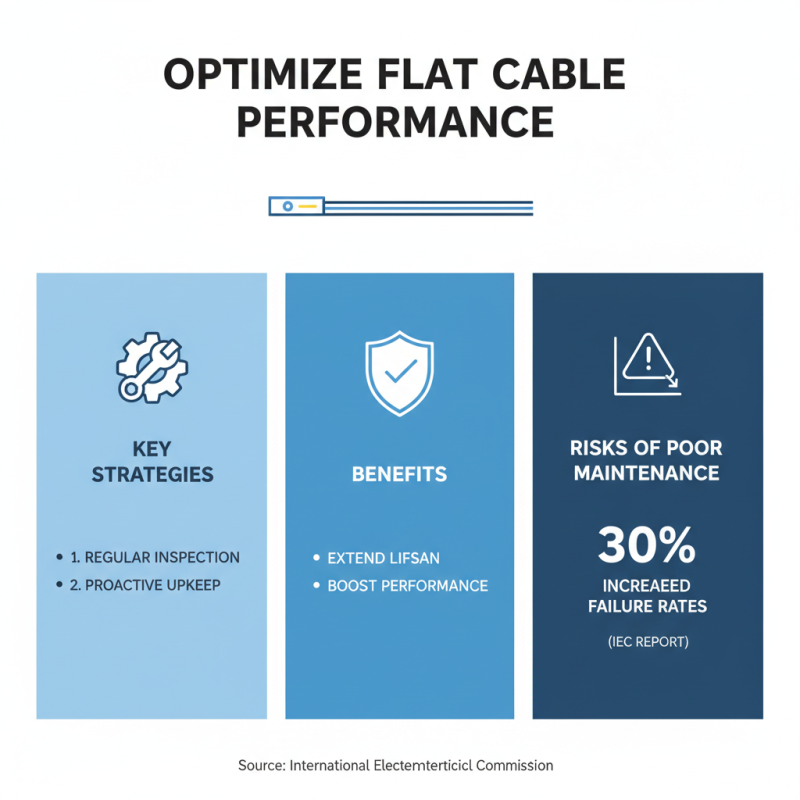

In maintaining the efficiency of your electrical system, adopting effective strategies for flat cable performance is essential. Regular inspection and proactive upkeep can significantly extend the lifespan and performance of flat cables. According to a report by the International Electrotechnical Commission, improper maintenance can lead to a 30% increase in failure rates, emphasizing the importance of systematic maintenance efforts.

One effective tip to optimize flat cable performance is to routinely check for physical damage. Inspecting for wear, corrosion, or any signs of insulation breakdown can prevent issues from escalating. Additionally, it's wise to use appropriate cable management systems to avoid mechanical stress that may arise from improper cable placement. Keeping cables organized and secured minimizes the risk of damage, contributing to better reliability.

Another key strategy is to maintain optimal operating conditions. Monitoring temperature and humidity levels is crucial, as excessive heat can lead to insulation failure and reduce electrical performance. Ensuring that the flat cables are installed in environments with stable conditions can help maintain their integrity. Regularly updating electrical system components alongside flat cables is also beneficial, as it ensures compatibility and optimal performance across the entire system.