Crane cables play a vital role in lifting heavy loads. These specialized cables are designed for cranes, ensuring both safety and efficiency. Understanding crane cables is essential for industries dependent on heavy machinery.

A crane cable consists of multiple strands of steel wire. This design allows for flexibility and strength. The cables are subjected to intense stress during operation. Regular inspections are necessary to avoid failures and potential accidents. Inadequate monitoring may lead to serious issues, which can be costly.

Crane cables also require proper maintenance. This involves checking for wear and tear regularly. Operators need to be aware of the cable's limit. Overloading can cause the cable to fray or snap. Proper training for operators is crucial to prevent mistakes and ensure safe operation.

Crane cable is an essential component in cranes, allowing them to lift heavy loads efficiently. Typically made from durable materials, it ensures strength and flexibility. Crane cables facilitate the lifting process by transmitting power from the crane’s motor to the load. When properly designed, they can withstand significant stress and tension.

Understanding crane cable is crucial for safety and performance. Various factors affect its reliability. For instance, the cable may wear over time or suffer from environmental damage. Regular inspections help detect these issues early. However, not everyone considers maintenance as a priority. This oversight can lead to dangerous situations on the job site.

Despite their importance, many overlook the significance of crane cables. Often, operators focus on the crane's overall functionality instead. Awareness of the specific needs and care of the cable can enhance safety. Moreover, keeping records of cable usage can prevent unforeseen failures. Adjustments in practices are necessary to prioritize safety and efficiency in crane operations.

Crane cables play a critical role in lifting operations. Their construction is essential for ensuring safety and functionality. Typically, crane cables are made from high-strength materials such as steel. The steel fibers are twisted together, creating a robust structure. This design allows the cables to endure heavy loads and resist wear.

In addition to steel, some cables contain synthetic fibers to improve flexibility. These fibers help reduce the overall weight of the cable while maintaining its strength. Wire ropes often have a core made from independent wires or fibers. This core provides extra support and enhances the cable’s overall durability. Interestingly, the diameter of the cables can vary, impacting their load-bearing capacity.

Regular maintenance is critical for crane cables. Fraying or damaged cables can lead to catastrophic results. Inspecting cables frequently is often overlooked but necessary. It’s not a glamorous task, yet it is vital. If a cable shows signs of wear, it should be replaced immediately. Ignoring these issues could result in accidents or equipment failures that are easily preventable.

Crane cables play a crucial role in the lifting and transporting of heavy loads. They function mechanically through a combination of tension and pulleys. The design and quality of a crane cable directly influence its performance. A well-crafted cable can support a weight of several tons without stretching or breaking.

In practice, crane cables operate by transmitting force through a series of sheaves and drums. Data suggests that a single heavy-duty cable can lift approximately 20% more than its standard rated load. This extra capacity allows for safety margins during operations. However, maintaining cables is vital. Wear and tear can decrease load capacity unexpectedly. Regular inspection is essential. Studies indicate that around 30% of crane accidents are linked to cable failure.

Mechanical systems must adapt to their environments. High temperatures or corrosion can weaken cables. This vulnerability is an area that needs serious attention in crane design. Engineers must consider these factors when designing lifting systems. The balance between cost and reliability remains a challenging aspect of crane cable production. Ensuring cables are both durable and cost-effective is an ongoing industry debate.

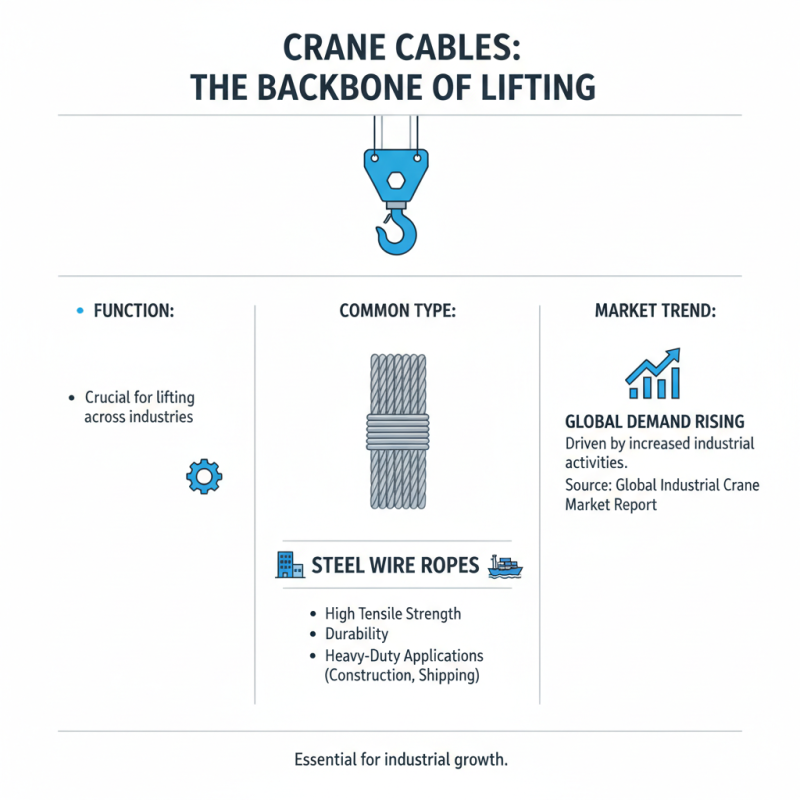

Crane cables play a crucial role in various lifting operations across industries. They come in several types, each designed for specific tasks. Steel wire ropes are the most common. They offer high tensile strength and durability, making them suitable for heavy-duty cranes used in construction and shipping. The Global Industrial Crane Market report states that the demand for steel wire ropes continues to rise, driven by increased industrial activities.

Synthetic cables are gaining attention due to their lightweight nature. They reduce fatigue on lifting equipment and offer corrosion resistance. This is essential in marine environments where saltwater can degrade materials quickly. Fiber rope is another option, valued for its flexibility and ease of handling. However, it may not withstand as much load as steel counterparts, requiring careful consideration.

**Tip 1:** Regularly inspect crane cables for wear and tear. Small frays can lead to larger problems, compromising safety.

**Tip 2:** Choose the right cable for the job. Underestimating weight and load can lead to dangerous situations.

Understanding the types of crane cables and their applications can enhance safety and efficiency in operations. This awareness can prevent costly mistakes and accidents in the workplace. Regular training and updates on cable technology can also foster better practices.

Crane cables are critical for safe and efficient lifting operations. Regular maintenance is essential to ensure their longevity and performance. A study from the International Association of Crane Safety reveals that 30% of crane incidents are linked to cable failures. Regular inspections can prevent such incidents. Operators should examine cables for signs of wear, fraying, or corrosion. Neglecting these checks can lead to accidents.

Safety considerations are paramount. Operators must adhere to guidelines set by industry standards. Proper training on handling and inspecting crane cables is vital. A report shows that inadequate training contributes to 25% of crane-related accidents. Operators should be educated on the correct techniques for rigging and maintenance. They must understand the load limits of the cables they use.

Environmental factors can impact cable integrity. Exposure to moisture and extreme temperatures can lead to deterioration. A survey indicates that environments with fluctuating temperatures increase the risk of cable failure by 40%. Regular monitoring and adapting maintenance practices to environmental conditions are necessary. Operators should remain vigilant to these risks.

| Dimension | Specification | Maintenance Frequency | Safety Considerations |

|---|---|---|---|

| Cable Diameter | 6-16 mm | Monthly | Inspect for wear and tear |

| Core Material | Steel Wire | Quarterly | Check lubrication levels |

| Operating Temperature | -20°C to 60°C | Biannual | Assess environmental factors |

| Load Capacity | Up to 10 tons | Weekly | Ensure load limits are not exceeded |