In the realm of lifting operations, the significance of choosing the right crane cable cannot be overstated. Crane cables are critical components that ensure safety and efficiency during material handling tasks. With various types available on the market, understanding the unique features and applications of each type can greatly enhance the durability and reliability of lifting systems. This article explores the top ten crane cable types, shedding light on their strengths, weaknesses, and ideal use cases.

As industries continue to evolve, the demands placed on lifting equipment have increased, necessitating a deeper focus on both safety and performance. Crane cables are not only subjected to heavy loads but also adverse environmental conditions that can impact their longevity. Therefore, selecting a cable that offers enhanced durability is essential for preventing failures that could lead to accidents. By examining the diverse array of crane cable types, this article aims to equip operators, engineers, and safety professionals with the knowledge needed to make informed decisions that contribute to safer lifting operations.

The selection of crane cables is a critical factor in ensuring safety during lifting operations. Crane cables are subjected to rigorous conditions, including heavy loads, dynamic movements, and environmental factors. It is essential to understand that the right cable type can significantly influence the overall safety and efficiency of the lifting process. Using cables designated for specific jobs not only enhances performance but also reduces the risk of accidents due to cable failure.

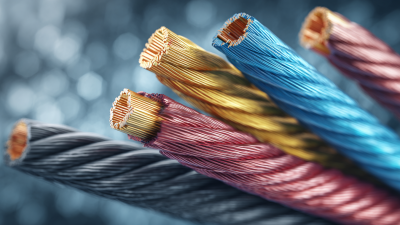

Moreover, a thorough understanding of the material properties, construction methods, and load capacities of different crane cables is vital. High-quality cables, such as those made from steel or synthetic fibers, offer improved durability and resistance to wear and fatigue. Operators must consider factors like environmental exposure, abrasion resistance, and tensile strength when selecting a crane cable. By prioritizing the correct cable type, companies can minimize operational risks, enhance safety protocols, and ultimately protect their workforce and equipment during lifting operations.

Crane cables play a crucial role in ensuring durability and safety during lifting operations. The selection of the right cable type can significantly enhance performance, preventing potential accidents and equipment failures. Key features that contribute to the durability of crane cables include the material composition—steel wire ropes are projected to dominate the steel wire rope market, which is estimated to reach USD 13.88 billion by 2030. These ropes offer superior tensile strength and resistance to wear and fatigue, making them ideal for heavy-duty applications.

Moreover, synthetic ropes are gaining traction, expected to grow from USD 1.77 billion in 2025 to USD 3.04 billion by 2033, reflecting a 7.04% CAGR. These ropes are lightweight and resistant to environmental factors such as moisture and UV rays, which enhances their lifespan in diverse operating conditions. Incorporating advanced technologies in the design and manufacturing of these cables, such as improved coatings and innovative construction techniques, further enhances their durability and safety. This transformation in cable technology is vital for powering landmark infrastructure projects, ensuring reliable performance in various lifting operations.

When it comes to crane operations, the choice of cable type can significantly affect both the durability of the equipment and the safety of lifting operations. In a comparative analysis of various crane cable types, it's essential to evaluate their mechanical response characteristics and overall performance under different conditions. Recent experimental assessments highlight the importance of energy consumption modes in knuckle boom cranes, indicating that the efficiency of the chosen cable can impact operational costs. This is vital as the market for industrial reels continues to grow, driven by necessary innovations in cable and hose management.

**Tips:** When selecting a crane cable, consider the material's tensile strength and resistance to wear and tear. It's crucial to match the cable type with the specific requirements of your lifting operation to enhance safety and reduce failures. Moreover, keep an eye on the evolving market trends, as new technologies may offer solutions that improve energy efficiency in your crane operations.

For operators, understanding the differences in cable types—such as wire rope versus synthetic cables—can lead to better decision-making. Wire ropes may provide superior load capabilities, while synthetic options may offer lighter weight and greater flexibility, enhancing overall lifting performance. Always prioritize safety ratings and manufacturer guidelines when making a choice to ensure reliability in demanding environments.

| Cable Type | Material | Breaking Strength (kN) | Weight (kg/m) | Durability Rating (Years) | Common Applications |

|---|---|---|---|---|---|

| Steel Wire Rope | Steel | 100 | 0.25 | 10 | Construction, Mining |

| Synthetic Fiber Rope | Polyester | 70 | 0.1 | 8 | Maritime, Rescue Operations |

| Chain Sling | Alloy Steel | 80 | 0.5 | 12 | Heavy Lifting, Construction |

| Wire Rope Sling | Steel | 90 | 0.3 | 9 | General Lifting, Heavy Industries |

| Braided Rope | Nylon | 60 | 0.15 | 6 | Light Duty, Recovery |

| Multi-strand Rope | Polypropylene | 75 | 0.2 | 7 | Agricultural, Domestics |

| Flat Web Sling | Polyester | 50 | 0.08 | 5 | Lifting Machinery, Furniture |

| Endless Rope | Polyester | 55 | 0.09 | 6 | Logistics, Warehousing |

| Round Sling | Nylon | 85 | 0.12 | 7 | Mechanical Assembly, Heavy Equipment |

| Specialty Cables | Various | Varies | Varies | Varies | Specialized Industrial Use |

The longevity of crane cables in lifting operations is influenced by several critical factors that operators must consider to ensure safety and efficiency. First and foremost, the material composition of the cables plays a significant role in their durability. Stainless steel cables, for example, offer excellent resistance to corrosion and are suited for harsh environments, while synthetic cables, such as those made from high-tensile polyethylene, provide lightweight options with exceptional shock absorption properties. The choice of material directly impacts both the operational life of the cable and its performance under stress.

Another key factor affecting the lifespan of crane cables is their maintenance routine. Regular inspections for signs of wear, kinks, or fraying are essential to prevent catastrophic failures during lifting operations. Proper lubrication can also reduce friction, thereby minimizing wear and tear. Furthermore, the conditions under which cables are used, including exposure to extreme temperatures and environmental challenges, should be assessed to determine appropriate usage and storage practices. By addressing these factors, operators can significantly enhance the durability and safety of crane cables, leading to more reliable lifting operations.

Maintaining crane cables is crucial for ensuring safety and performance during lifting operations. Regular inspections should be conducted to identify any signs of wear, fraying, or corrosion that can compromise cable integrity. Operators must understand the specific danger zones associated with crane usage, such as avoiding areas where loads are suspended. A culture of safety can significantly reduce the risk of accidents, including those caused by electrical exposure, as evidenced by recent statistics showing a decrease in fatal work injuries.

**Tips for Cable Maintenance:**

1. Perform regular visual inspections of crane cables to catch potential issues early.

2. Implement a cleaning routine to remove dirt, debris, and corrosive substances that can lead to cable deterioration.

3. Train operators to stay clear of the area beneath suspended loads and use IoT technology for remote operation when possible, minimizing risks associated with proximity to the crane.

Using IoT-connected cranes enables operators to monitor and control the equipment from a safe distance, further enhancing safety measures. Ensuring that cables are kept in optimal condition not only prolongs their lifespan but also secures the safety of personnel involved in lifting operations.