Choosing the right material for your electrical projects is crucial. One of the key components you must consider is the "Direct Burial Wire." This type of wire is specially designed for underground installation. It can resist moisture, corrosion, and temperature changes effectively. Without adequate protection, wires can fail quickly when exposed.

When you're selecting Direct Burial Wire, think about your project's specific needs. Not all environments are the same. Factors like soil condition and moisture levels can greatly impact the wire's performance. Moreover, always double-check the wire's ratings. It should meet local codes to ensure safety and compliance.

Selecting Direct Burial Wire can seem straightforward, but it requires careful thought. Ignoring any detail can lead to regrets later on. Poor choice can result in damaged wires or even safety hazards. Pay attention to the nuances of each option you consider. A little extra time invested in the selection process will pay off in durability and safety.

When selecting direct burial wire for electrical projects, understanding its features and benefits is crucial. Direct burial wire is designed specifically for underground installation. It must withstand moisture, soil pressure, and corrosion. According to the National Electrical Manufacturers Association (NEMA), using the right wire can significantly reduce maintenance costs. The wire's insulation ensures it's safe against physical damage despite harsh environments.

Tips for choosing the right wire include checking the insulation material. THHN wire is a common choice because it resists moisture well. Another vital consideration is the wire gauge, which affects both current capacity and installation ease. For instance, thicker wires generally handle higher amperage but can be harder to work with. Remember, improper gauge selection can lead to overheating, which may cause system failure.

It’s also essential to consider your area's climate. Underground wires must handle specific temperature ranges. Installation practices can sometimes overlook local codes. This oversight can lead to future issues that are costly to rectify. Staying informed about the guidelines helps in making better choices. Each project may have unique requirements, making it imperative to double-check specifications before proceeding.

This chart illustrates the relative importance of various factors when choosing direct burial wire for your projects. Each factor is rated on a scale from 1 to 10, with higher values indicating greater importance.

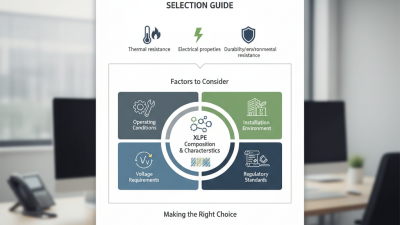

When selecting wire for burial applications, several key considerations come into play. Firstly, the

insulation material is crucial. For direct burial, choose

PVC or XLPE insulation.

These are designed to resist moisture and protect the wire from soil chemicals. Reports indicate that

failures often occur due to inadequate insulation. Over 40% of

issues stem from improper wire selection.

Conductor size is another important factor. Use larger conductors for longer distances. This reduces voltage drop, enhancing performance.

According to industry data, a voltage drop of 3% is acceptable for residential projects. However, exceeding this can lead to inefficiencies.

It is also vital to check local codes. They may dictate specific requirements for burial wire, impacting your project’s compliance.

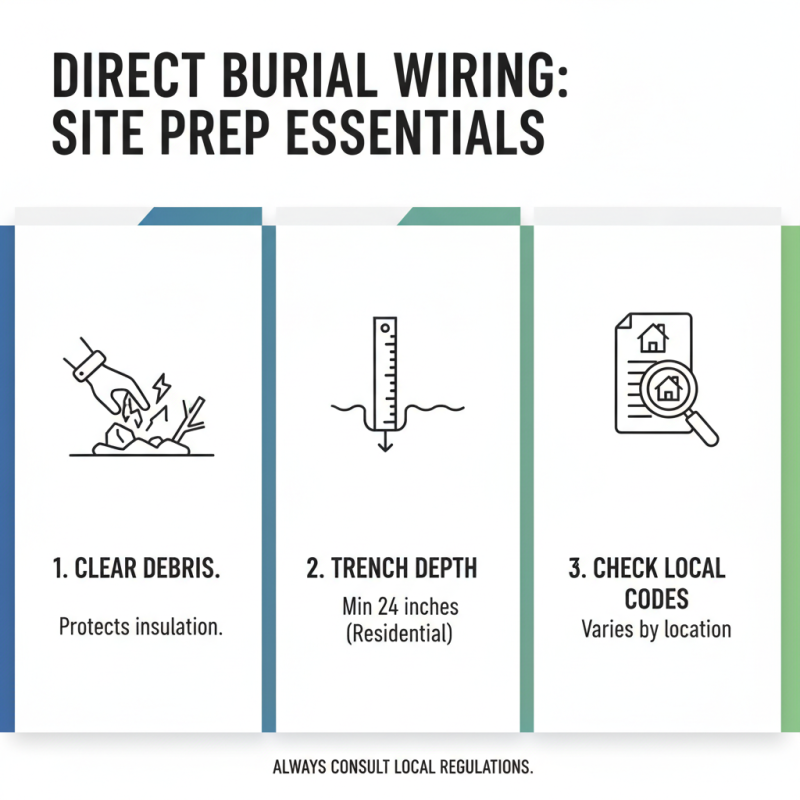

Additionally, consider the burial depth. Standard guidelines

recommend at least 24 inches for direct burial. However, this can

vary based on local regulations. Depth affects both safety and durability. Every project may present unique

challenges. Assessing soil conditions and potential hazards is essential. This thorough examination can

prevent unexpected issues down the road.

When selecting direct burial wires, understanding the different types is crucial. There are many options, each designed for specific applications. Some wires are insulated with durable materials, ensuring they resist moisture and chemical exposure. Others may lack this insulation, making them unsuitable for certain environments. The right choice can save you time and money.

Consider the wire gauge. Thicker wires can handle more voltage. They’re often necessary for long-distance projects. Thinner wires can be cheaper but may lead to issues down the road. This is an important detail that some overlook. Pay attention to local codes as well. They often dictate what types of wire can be used underground.

Another aspect to think about is installation conditions. Will there be a risk of rodent damage? Some wires come with added protection against such threats. However, they might be heavier and harder to work with. It’s essential to balance protection with ease of use. Rushing this choice could lead to future headaches.

When selecting direct burial wire, assessing environmental conditions is crucial. Soil moisture, temperature variations, and exposure to chemicals can significantly impact wire performance. According to the National Electrical Manufacturers Association (NEMA), corrosion-resistant materials are vital. They found that wires buried in damp soils deteriorate faster, reducing their lifespan.

Temperature fluctuations can also affect the wire. Research from the Institute of Electrical and Electronics Engineers (IEEE) indicates that extreme heat can lead to insulation breakdown. In contrast, cold temperatures can make the wire brittle. Consider local climate conditions before making a decision.

Soil type plays a significant role too. Sandy soils drain well but can expose wires to air. Conversely, clay soils retain moisture, creating a damp environment. Additionally, buried wires must withstand potential physical damage from landscaping or construction activities. This constant tension raises further concerns about wire integrity. Remember, each project has unique factors to evaluate. Missing these details could result in costly repairs.

| Tip Number | Environment | Temperature Range (°C) | Soil Type | Moisture Level | Wire Type Recommended |

|---|---|---|---|---|---|

| 1 | Cold Climate | -30 to 10 | Clay | Low | Thermoplastic |

| 2 | Temperate Zone | 0 to 35 | Sandy | Medium | Cross-linked Polyethylene |

| 3 | Hot and Humid | 20 to 50 | Loamy | High | PVC Insulated Wire |

| 4 | Desert | 10 to 40 | Rocky | Low | Weather-Resistant Insulation |

| 5 | Wetlands | 0 to 25 | Muddy | Very High | Submersible Cable |

| 6 | Urban | -10 to 35 | Concrete | Medium | Armored Cable |

| 7 | Forest Area | -10 to 30 | Loamy | Medium | Direct Burial Cable |

| 8 | Swamp Area | 0 to 25 | Silty | High | Waterproof Insulated Cable |

| 9 | Mountainous | -20 to 15 | Rocky | Low | Heavy Duty Cable |

| 10 | Coastal | 10 to 30 | Sandy | Medium | Corrosion-Resistant Wire |

When installing direct burial wiring, preparing the site is crucial. Clear the area of any debris or sharp objects. This helps prevent insulation damage. Choose the right depth for your trenches. At least 24 inches is often recommended for residential use. However, local codes can vary, so always check.

Using suitable materials is just as important. Opt for wire rated for underground use, which can resist moisture and corrosion. **Keep in mind** that not all wires are equal. Make sure the connectors you choose are also rated for underground environments. This helps ensure longevity and safety.

Testing the wire before burying it is wise. Conduct a continuity test to ensure there are no breaks. Mistakes here can lead to serious consequences. A well-planned project saves time and money later on. Regular inspections and maintenance are essential too. They can prevent potential issues from escalating. Always reflect on your install method and make improvements for future projects.