In the ever-evolving world of electrical engineering, understanding the “Iec Cable Meaning” is paramount for both professionals and enthusiasts. According to a report by the International Electrotechnical Commission (IEC), the global market for IEC standard cables is projected to reach $35 billion by 2025, underscoring the importance of compliance and quality in electrical installations. Expert John Mitchell, a leading authority in cable technology, emphasizes that “knowledge of IEC cable standards is crucial for ensuring safety and reliability in electrical systems.”

The significance of IEC cables cannot be overstated; they play a vital role in various applications, from residential wiring to industrial power distribution. By adhering to IEC standards, engineers can mitigate risks associated with electrical failures, which can result in costly downtime and safety hazards. Learning about the meaning and specifications of IEC cables not only empowers professionals to make informed decisions but also enhances project efficiency and safety outcomes. As the industry continues to grow, understanding the “Iec Cable Meaning” will be essential for anyone looking to thrive in this high-stakes environment.

IEC cables, or International Electrotechnical Commission cables, play a pivotal role in various electrical applications. Understanding the basics of these cables is essential for professionals in the electrical engineering sector, as they ensure safety and efficiency in electrical installations. According to a market report by MarketsandMarkets, the global market for IEC cables is expected to reach $200 billion by 2025, reflecting a compound annual growth rate (CAGR) of approximately 5%. This growth underscores the increasing demand for reliable electrical components in both industrial and residential sectors.

When selecting IEC cables, it is crucial to understand their specifications, including voltage rating, conductor material, and insulation type. IEC 60228 outlines the classification of conductors used in cables, which is fundamental for compliance and safety. Furthermore, the IEC 60332 standard addresses flame propagation, emphasizing the importance of using cables that meet stringent safety guidelines. As regulations evolve, engineers must stay updated on standards to ensure their installations are compliant and safe, thereby minimizing the risk of electrical faults and enhancing overall system performance.

IEC cables, defined by the International Electrotechnical Commission, are critical components in electrical installations. Their design and construction are governed by specific standards that ensure safety, reliability, and performance. One key characteristic is their flexibility, allowing for easy routing in complex setups. Additionally, IEC cables are typically built with high-quality materials, enhancing durability and resistance to environmental factors.

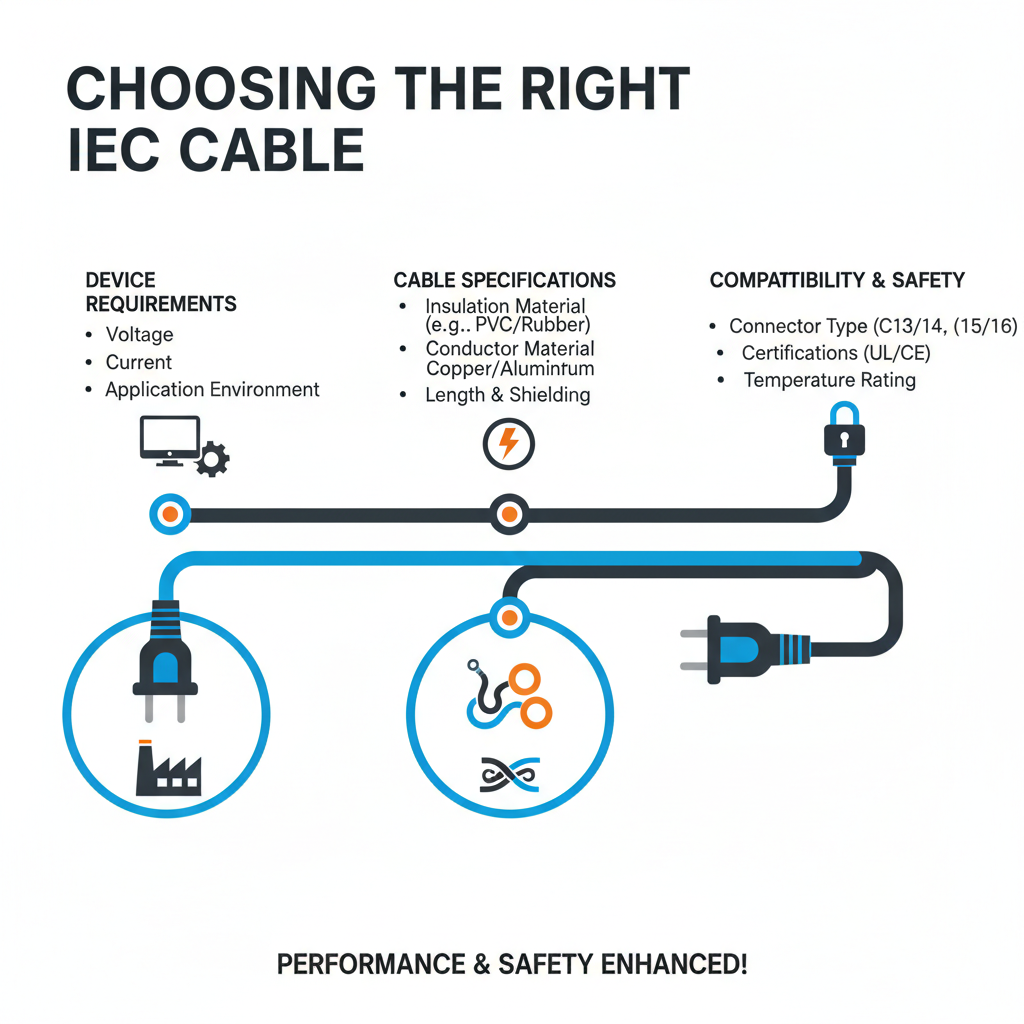

When selecting IEC cables, it’s essential to consider compatibility with your system’s voltage and current ratings. One tip is to always check the cable’s insulation type, as it significantly affects performance in various conditions. For outdoor applications, look for cables with UV-resistant sheathing to extend their lifespan. Furthermore, ensure proper labeling of cables, which helps in maintenance and troubleshooting.

Another important aspect of IEC cables is their compliance with international safety regulations. This provides peace of mind for users, knowing that their installations meet global standards. It’s advisable to purchase certified cables from reputable manufacturers to ensure quality and adherence to IEC specifications. Lastly, consider the cable’s temperature rating to guarantee optimal performance in different environments.

IEC cables play a crucial role in various industrial applications due to their reliability and adherence to international standards. Commonly utilized in sectors like renewable energy, telecommunications, and manufacturing, IEC cables ensure safe and efficient power distribution. For instance, in the renewable energy industry, IEC cables are integral for connecting solar panels and wind turbines to the grid. According to a report by Research and Markets, the global market for IEC-compliant cables is projected to grow by 5.2% annually, underscoring the rising demand in electricity-generating sectors.

When selecting IEC cables for industrial applications, keep these essential tips in mind: first, always consider the cable's insulation and temperature ratings to ensure it meets the operational environment's requirements. Additionally, ensure that the cables comply with relevant IEC standards to avoid potential regulatory issues. Lastly, evaluate the project’s specific needs, such as flexibility and durability, which can greatly impact installation and long-term performance.

In the telecommunications industry, IEC cables are indispensable for high-speed data transfer and connectivity. A survey conducted by the International Telecommunication Union found that the demand for high-quality cables is expected to double by 2025, driven by the growth of 5G networks and increased bandwidth requirements. Ensuring the right IEC cables are used can enhance network efficiency significantly, making them a vital component in modern communication infrastructure.

When dealing with IEC cables, understanding safety standards and regulations is paramount to ensuring both performance and safety in electrical installations. The International Electrotechnical Commission (IEC) has established a comprehensive framework for cables that includes guidelines on insulation, temperature ratings, and conductivity. These standards help in mitigating risks related to electrical shock, fire hazards, and equipment failure, which can occur due to faulty wiring or improper installations.

Moreover, compliance with IEC standards not only enhances safety but also ensures compatibility across various electrical systems globally. This is particularly critical in industrial applications where equipment is often subject to rigorous operational demands. Organizations must ensure that the IEC cables they use are certified and compliant with the relevant safety standards, such as IEC 60227 for PVC insulated cables or IEC 60502 for cables with extruded insulation. Regular inspections and adherence to these regulations are vital in maintaining operational safety and efficiency in any electrical system.

When it comes to choosing the right IEC cable for your needs, understanding the specific requirements of your devices is crucial. IEC cables come in various types and specifications, each suited for different applications. Whether you're connecting to industrial machinery, audio-visual equipment, or computing devices, it’s important to ensure compatibility in terms of voltage, current, and application environment. For instance, selecting a cable with the right insulation and conductor material can significantly enhance performance and safety.

Another key consideration is the cable's length and flexibility. Longer cables may introduce voltage drop, impacting performance, while highly flexible cables allow for easier installation in tight spaces. With the rise of various electronic devices and systems, it's essential to pick a cable that not only meets safety standards but also aligns with the operational requirements of your equipment. By staying informed and paying attention to these factors, you can make an informed decision that supports optimal functionality and safety in your electrical setups.