Water pump cables play a crucial role in ensuring the efficient operation of various water pumping systems, from agricultural irrigation to municipal water supply. According to a report by the National Electrical Manufacturers Association (NEMA), nearly 60% of water treatment facilities rely on reliable water pump cables to maintain uninterrupted service and prevent costly downtimes. These specialized cables are designed to withstand harsh environmental conditions, including extreme temperatures and exposure to water, making the selection of high-quality cables paramount for optimal performance. Poorly designed or unsuitable water pump cables can lead to significant energy losses, potentially increasing operational costs by up to 20%, as highlighted in a study by the American Society of Mechanical Engineers (ASME). Therefore, understanding the intricacies of water pump cables is essential for industry professionals looking to enhance the efficiency and longevity of their water pumping systems.

Water pump cables play a crucial role in ensuring the efficient operation of various water pumping systems, from agricultural irrigation to municipal water supply. According to a report by the National Electrical Manufacturers Association (NEMA), nearly 60% of water treatment facilities rely on reliable water pump cables to maintain uninterrupted service and prevent costly downtimes. These specialized cables are designed to withstand harsh environmental conditions, including extreme temperatures and exposure to water, making the selection of high-quality cables paramount for optimal performance. Poorly designed or unsuitable water pump cables can lead to significant energy losses, potentially increasing operational costs by up to 20%, as highlighted in a study by the American Society of Mechanical Engineers (ASME). Therefore, understanding the intricacies of water pump cables is essential for industry professionals looking to enhance the efficiency and longevity of their water pumping systems.

Water pump cables are essential components in ensuring the optimal performance of water pumping systems. Understanding the different types of water pump cables is crucial for selecting the right one for your specific needs. Typically, these cables fall into categories such as submersible pump cables, non-submersible pump cables, and flat or round cables, each designed to meet specific operational requirements.

Submersible pump cables, for instance, are designed to withstand the harsh conditions of underwater environments. According to a report by the National Electrical Manufacturers Association (NEMA), these cables are typically made with high-quality insulation materials that provide superior resistance to chemicals and abrasion, thereby extending their lifespan. Conversely, non-submersible cables are suited for above-ground installations and can often use simpler insulation because they are not exposed to water; however, they must still adhere to industry standards to withstand outdoor conditions. Furthermore, flat cables are often preferred for installation in confined spaces due to their flexibility, making them easier to handle and install.

Selecting the right type of water pump cable not only enhances performance but also minimizes downtime. A report by the International Electrotechnical Commission (IEC) indicates that proper cable choice can lead to a reduction in energy losses of up to 30%, which emphasizes the impact of quality cables on overall system efficiency. Therefore, understanding these cable types and their applications is vital for achieving optimal water pumping performance.

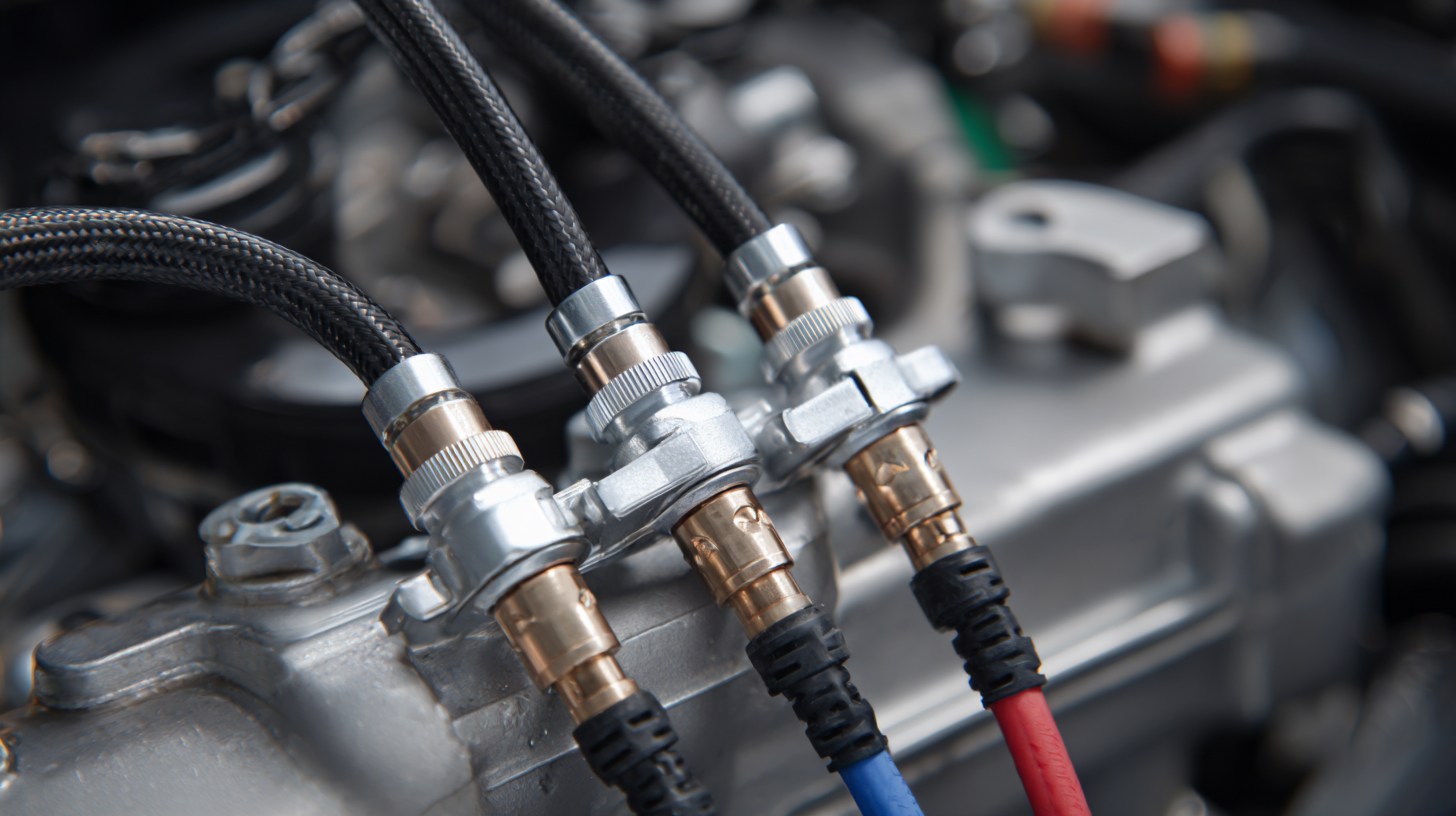

When selecting water pump cables, it's crucial to understand the key features that contribute to optimal performance. First, the cable's insulation material plays a significant role in its durability and resistance to moisture and chemicals. High-quality cables often utilize thermoplastic elastomers (TPE) or polyvinyl chloride (PVC), which offer superior flexibility and protection against environmental factors. Additionally, the cable's temperature rating ensures it can withstand the heat generated by the pump without degrading over time.

**Tip:** Always check the manufacturer's specifications for the insulation type and temperature rating before making a purchase.

Another vital feature is the cable's wire gauge. A thicker wire gauge (lower AWG number) can carry more current and reduce energy loss, making it ideal for high-capacity pumps. Furthermore, look for cables with robust connectors designed for underwater use, as these will prevent corrosion and ensure a reliable connection for years to come.

**Tip:** Opt for cables with an abrasion-resistant exterior to prolong their lifespan, especially in environments with potential wear and tear.

By being mindful of these features, you can ensure that your water pump operates efficiently and reliably, ultimately saving time and money on maintenance and replacements.

| Feature | Description | Importance |

|---|---|---|

| Conductor Material | Typically made from copper or aluminum to ensure efficient current flow. | Copper offers superior conductivity, enhancing pump performance. |

| Insulation Type | Insulation materials like PVC or rubber protect against moisture and abrasion. | Quality insulation prevents electrical shorts and enhances safety. |

| Voltage Rating | Indicates the maximum voltage the cable can safely handle. | Using the correct voltage rating ensures optimal pump operation and longevity. |

| Temperature Rating | Cables are rated for different temperature ranges based on application needs. | High-temperature ratings prevent insulation breakdown in harsh environments. |

| Flexibility | Cables designed to bend and flex without damage facilitate installation. | Improved flexibility allows for easier maneuvering in tight spaces. |

| Length Options | Available in various lengths to suit different installation requirements. | Correct length minimizes connections and prevents voltage loss. |

| Certification | Look for cables with certifications like UL or CSA. | Certifications ensure compliance with safety and performance standards. |

When selecting water pump cables, understanding voltage ratings is crucial for ensuring optimal performance and longevity. Voltage ratings indicate the maximum voltage a cable can handle safely without the risk of electrical breakdown. According to the National Electrical Manufacturers Association (NEMA), cables that exceed their voltage ratings can lead to insulation breakdown, increasing the risk of electrical failures and posing safety hazards. It is essential to match the voltage rating of the cable with the pump's operational voltage to avoid overheating and premature cable deterioration.

When selecting water pump cables, understanding voltage ratings is crucial for ensuring optimal performance and longevity. Voltage ratings indicate the maximum voltage a cable can handle safely without the risk of electrical breakdown. According to the National Electrical Manufacturers Association (NEMA), cables that exceed their voltage ratings can lead to insulation breakdown, increasing the risk of electrical failures and posing safety hazards. It is essential to match the voltage rating of the cable with the pump's operational voltage to avoid overheating and premature cable deterioration.

Tip: Always check the pump manufacturer’s specifications for recommended cable types and voltage ratings to avoid costly mistakes.

Additionally, different environments can affect cable performance. For instance, cables in harsh outdoor environments may need higher voltage ratings and robust insulation to withstand moisture and UV exposure. The Institute of Electrical and Electronics Engineers (IEEE) suggests using cables with a safety margin of at least 10% above the system's maximum operational voltage. This margin not only accommodates voltage spikes but also extends the cable’s lifespan.

Tip: Regularly inspect cables for signs of wear and degradation, especially in outdoor settings, and replace them at first signs of damage to maintain operational efficiency.

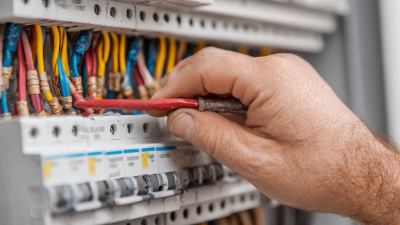

When it comes to ensuring the longevity and optimal performance of water pump cables, installation best practices play a pivotal role. Properly selecting the right type of cable designed for water pump applications is the first step. It's crucial to choose cables that are resistant to moisture and environmental factors to prevent degradation over time. Additionally, employing the appropriate gauge for your specific pump capacity will help manage the electrical load effectively.

In terms of installation, securing cables away from potential hazards, such as sharp edges or excessive heat sources, can significantly reduce wear and tear. Utilizing protective conduits and ensuring sufficient slack in the cable during installation will also minimize stress, allowing for natural movement without compromising electrical integrity.

Regular maintenance checks can help identify any signs of wear early on, which is vital for maintaining the operational efficiency of water pumps and preventing unplanned downtimes or failures.

Key Takeaway: Proper installation and regular maintenance are essential for ensuring the efficiency and durability of water pump cables.

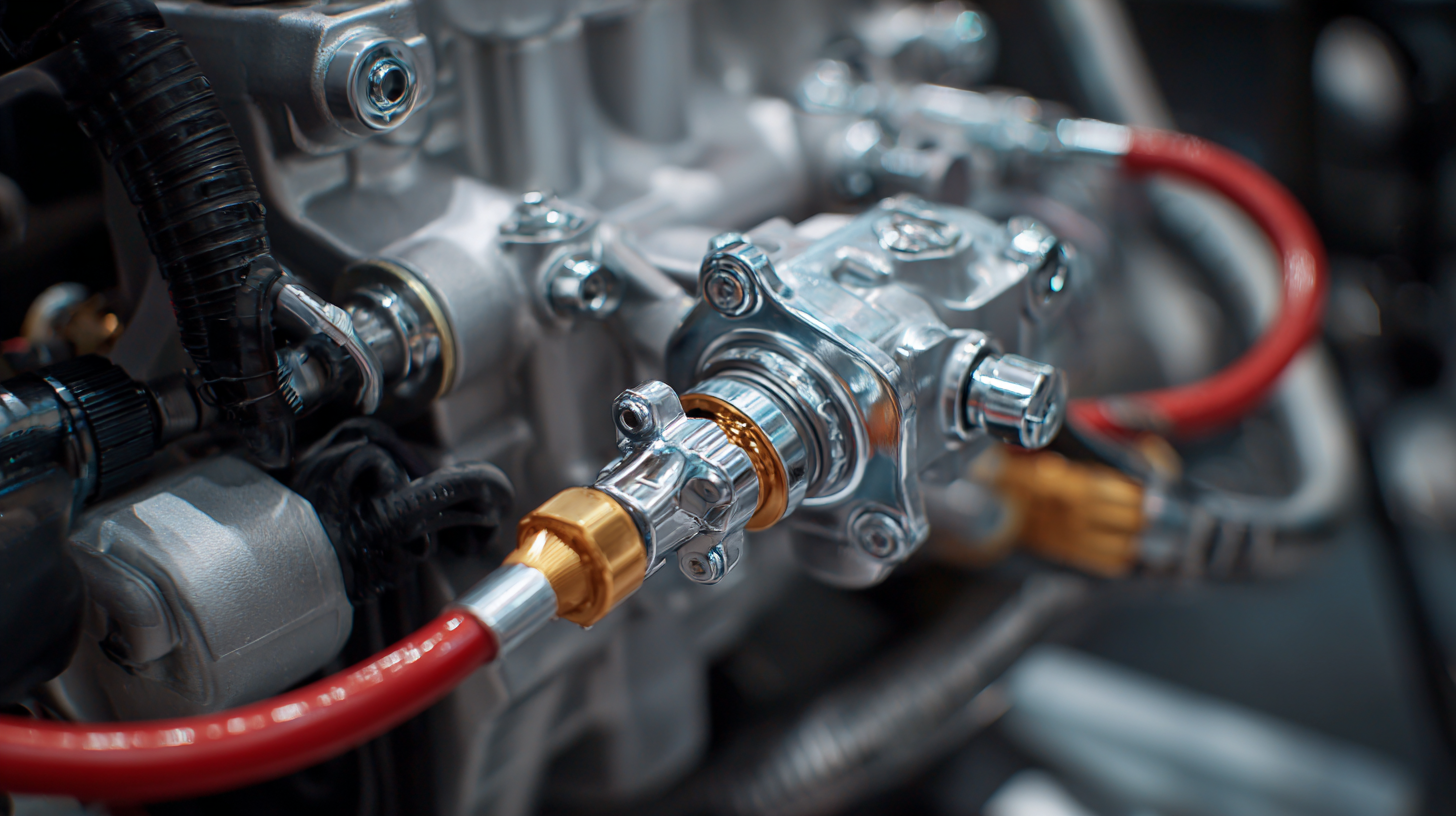

Maintaining water pump cables is crucial for ensuring optimal performance and longevity. One of the common challenges faced by operators is cable insulation breakdown, which can occur due to factors such as moisture ingress, UV exposure, and mechanical stress. According to a report by the International Water Association, approximately 30% of water infrastructure failures are attributed to inadequate cable maintenance. To mitigate these issues, regular inspections and using high-quality, environmentally resistant materials can significantly extend the lifespan of water pump cables.

Another significant challenge is cable overheating, which can lead to reduced efficiency and potential pump failure. A study by the Electric Power Research Institute indicates that around 25% of pump inefficiencies can be traced back to poor cable connections and improper sizing. Proper installation practices, including ensuring appropriate cable gauge and secure terminations, are essential for preventing overheating. Implementing routine thermal imaging assessments can help operators identify hot spots in their systems, allowing them to take corrective actions before costly failures occur. By addressing these challenges head-on, operators can enhance the reliability of their water pumping systems and reduce operational costs.