Three Phase Armoured Cable plays a pivotal role in modern electrical distribution systems, providing a robust and reliable means of power transmission. As the demand for efficient energy solutions continues to rise—projected to increase by over 3% annually through 2026, according to the International Energy Agency—understanding the applications, benefits, and installation tips for this type of cable is more important than ever. The three-phase system, renowned for its efficiency in transmitting large amounts of power, is widely adopted in industrial and commercial settings, where uninterrupted power supply is crucial.

The use of armoured cables not only ensures greater resistance against mechanical damage but also enhances safety, making them suitable for harsh environments. Reports from the Global Cable Market indicate that the demand for armoured cables, particularly in the power sector, is expected to grow significantly, highlighting a shift towards more durable infrastructure. Thus, exploring the intricacies of Three Phase Armoured Cable not only aids engineers and technicians in selecting the appropriate cabling solutions but also underscores the importance of adhering to best practices during installation to maximize performance and longevity. In this article, we delve into the various applications, inherent benefits, and essential installation tips that will contribute to the effective utilization of Three Phase Armoured Cable in existing and future energy projects.

Three-phase armoured cable is designed to provide a robust solution for electrical power distribution in various industrial and commercial settings.

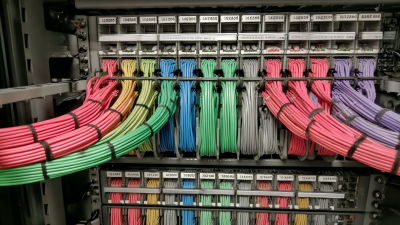

The structure of this cable typically includes three insulated conductors for the three phases of electrical supply, which are encased in a protective layer of armor.

This armor, usually made from steel or aluminum materials, adds significant durability to the cable, allowing it to withstand harsh environmental conditions, mechanical impacts, and potential rodent damage.

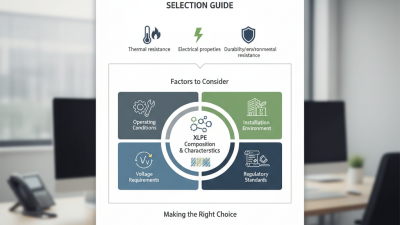

The insulation materials used in three-phase armoured cables are critical for their performance.

They are designed to handle higher voltage levels and to resist moisture and chemical exposure, ensuring longevity and reliability in electrical installations.

Additionally, the overall construction often includes an outer sheath that further protects the inner components from external factors.

This combination of features makes three-phase armoured cables suitable for a wide range of applications, including underground installations and outdoor use, where resilience and safety are paramount.

Understanding the structural elements of these cables is essential for selecting the appropriate product for specific electrical requirements.

Three-phase armoured cables are essential in various industrial applications due to their robust design and reliable performance. These cables are engineered to transmit three-phase electrical power, making them ideal for heavy machinery and large-scale operations. One common application is in manufacturing plants, where powering motors, conveyors, and various automated systems is crucial for maintaining production efficiency. The resistance to environmental and mechanical stress allows these cables to function effectively in demanding conditions, such as in factories, where exposure to chemicals and physical impacts is common.

Another significant application is in construction sites, where three-phase armoured cables provide the necessary power for tools and equipment. Their durability ensures safe operation in rugged environments, mitigating the risk of damage from external influences. Furthermore, these cables are extensively used in commercial buildings to support HVAC systems, elevators, and lighting systems, highlighting their versatility. The choice of armoured cables in these settings ensures a continuous and stable power supply, which is critical for operational reliability and safety in both industrial and commercial applications.

Three phase armoured cables are essential components in modern electrical systems, offering numerous benefits for both commercial and industrial applications. According to industry reports, the demand for reliable and durable wiring solutions has surged, with a growth rate projected to reach 7% annually over the next five years. These cables are designed to withstand harsh environmental conditions, making them ideal for outdoor installations and high-risk areas. With their enhanced durability, the risk of damage from mechanical impacts or environmental factors is significantly reduced, leading to increased safety and longevity of electrical systems.

One of the key benefits of three phase armoured cables is their ability to handle high power loads efficiently. These cables can manage large currents and maintain a stable power supply, which is particularly crucial in industries such as manufacturing and construction. Research indicates that using three phase systems can lead to a reduction in energy losses by up to 30% compared to single-phase systems. Furthermore, their armoured construction provides added protection against electromagnetic interference, ensuring that the integrity of the electrical signals remains intact.

When installing three phase armoured cables, consider the following tips for optimal performance:

When installing three phase armoured cables, adherence to best practices is crucial for ensuring safety and efficiency. Before beginning the installation, it is essential to plan the route meticulously. This includes avoiding areas with potential physical damage, assessing environmental conditions, and ensuring compliance with local electrical codes. Accurate measurements should be taken to determine the appropriate length of the cable, allowing for any potential bends or turns in the installation area, thus minimizing stress on the cable.

Safety precautions should also be a top priority during installation. This begins with verifying that the power supply is turned off before any work commences. Using appropriate personal protective equipment (PPE) such as gloves, goggles, and helmets can help protect against potential hazards. Additionally, it is advisable to use quality connectors and junction boxes designed for armoured cables to maintain the integrity of the connections. Lastly, ensuring adequate grounding throughout the installation helps prevent electrical faults, enhancing the overall safety of the system. By following these tips, installers can maximize the performance and lifespan of three phase armoured cables while safeguarding both the installation team and the surrounding environment.

Regular maintenance and troubleshooting of three-phase armoured cables are essential for ensuring their optimal performance and longevity. According to the International Electrotechnical Commission (IEC), approximately 30% of electrical failures can be attributed to inadequate cable maintenance. This statistic underscores the importance of routine inspections, which should focus on mechanical integrity, insulation condition, and any signs of physical damage. For instance, cable sheath integrity is critical, as any breaches could expose the inner conductors to environmental stressors, leading to short circuits or failures. Regular visual inspections along with advanced diagnostic techniques such as thermal imaging and capacitance testing can aid in identifying potential issues before they culminate in costly outages.

In terms of troubleshooting, it is crucial to adopt a systematic approach. An estimated 40% of issues arise from improper installation practices, such as inadequate bending radii or excessive tension during laying. Therefore, keeping clear documentation of installation parameters can facilitate quicker diagnostics if performance issues arise. Additionally, employing fault location techniques like time-domain reflectometry (TDR) can significantly enhance the efficiency of troubleshooting efforts. By identifying the exact location of a fault within the cable, maintenance teams can reduce downtime and minimize disruptions to the electrical supply. Utilizing these maintenance and troubleshooting strategies not only preserves the integrity of three-phase armoured cables but also ensures compliance with safety standards set forth by organizations such as the Institute of Electrical and Electronics Engineers (IEEE), which advocate for rigorous performance monitoring for improved reliability.