In the quest for enhanced electrical efficiency and performance, the choice of wiring plays a critical role, particularly when considering Single Conductor Wire. With the global energy demand projected to rise by over 25% by 2030, as indicated by the International Energy Agency (IEA), the importance of optimizing electrical systems cannot be overstated. Single Conductor Wires, known for their simplicity and effectiveness, have emerged as a preferred solution in various applications ranging from residential to industrial settings.

Recent reports from the National Electrical Manufacturers Association (NEMA) highlight that the use of appropriate wiring significantly reduces energy losses, which can account for up to 30% of operational costs in electrical systems. Furthermore, advancements in wire materials and insulation technologies promise not only improved performance but also longevity and safety in electrical installations. As we delve into the top 10 Single Conductor Wire options for 2025, it is essential to consider the evolving landscape of the electrical industry and the implications that these selections bear on sustainable practices and cost efficiency.

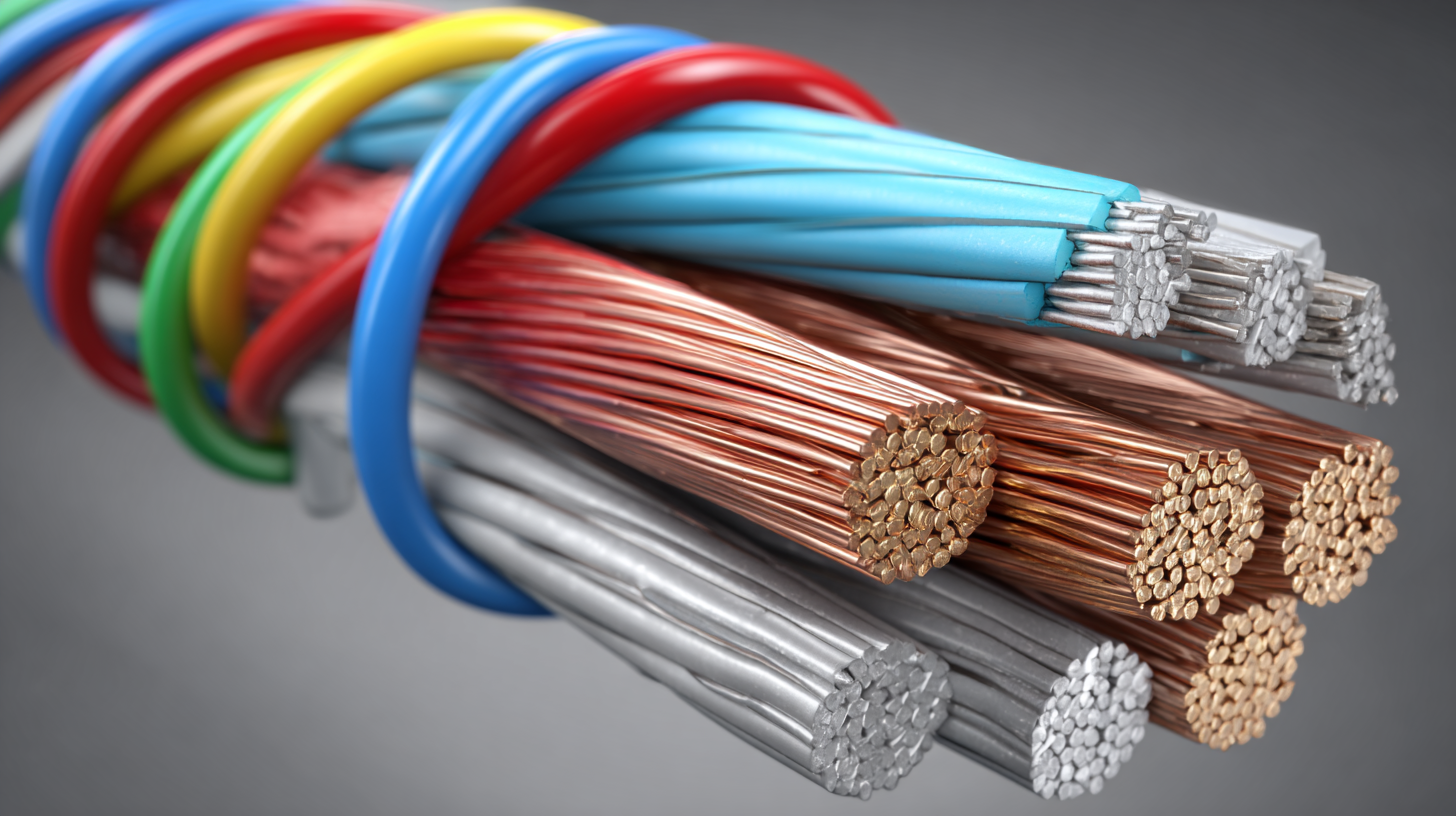

Single conductor wires are becoming increasingly popular in modern electrical systems due to their numerous benefits in efficiency and performance. One significant advantage is their ability to reduce energy loss. Unlike multi-stranded wires, single conductor wires offer a direct pathway for electrical flow, minimizing resistance and thus decreasing heat generation. This feature is particularly beneficial in applications requiring long-distance transmission, where energy efficiency becomes pivotal.

Additionally, single conductor wires provide improved reliability and durability. Their simple construction makes them less prone to mechanical stress and environmental damage, ensuring a longer lifespan and decreased maintenance requirements. This reliability is crucial in critical systems such as telecommunications and renewable energy, where uninterrupted power supply is essential. Overall, the adoption of single conductor wires not only enhances the operational efficiency of electrical systems but also aligns with the growing demand for sustainable and resilient infrastructure.

| Wire Type | Voltage Rating (V) | Current Capacity (A) | Resistance (Ohms/km) | Temperature Rating (°C) | Application |

|---|---|---|---|---|---|

| Copper | 600 | 20 | 17.2 | 90 | Residential Wiring |

| Aluminum | 600 | 15 | 28.2 | 75 | Power Distribution |

| Tinned Copper | 600 | 30 | 17.2 | 90 | Marine Applications |

| XLPE Insulated | 1,000 | 25 | 12.1 | 90 | Industrial Wiring |

| PVC Insulated | 600 | 20 | 18.6 | 75 | General Purpose |

| Silicone Insulated | 600 | 10 | 22.5 | 200 | High-Temperature Applications |

| Low Smoke Zero Halogen (LSZH) | 600 | 15 | 24.3 | 90 | Building Wiring |

| Flex (Stranded) | 600 | 25 | 19.8 | 75 | Mobile Equipment |

| Shielded Wire | 600 | 30 | 15.8 | 90 | Data Transmission |

| High Voltage Cable | 33,000 | 100 | 3.0 | 90 | Power Transmission |

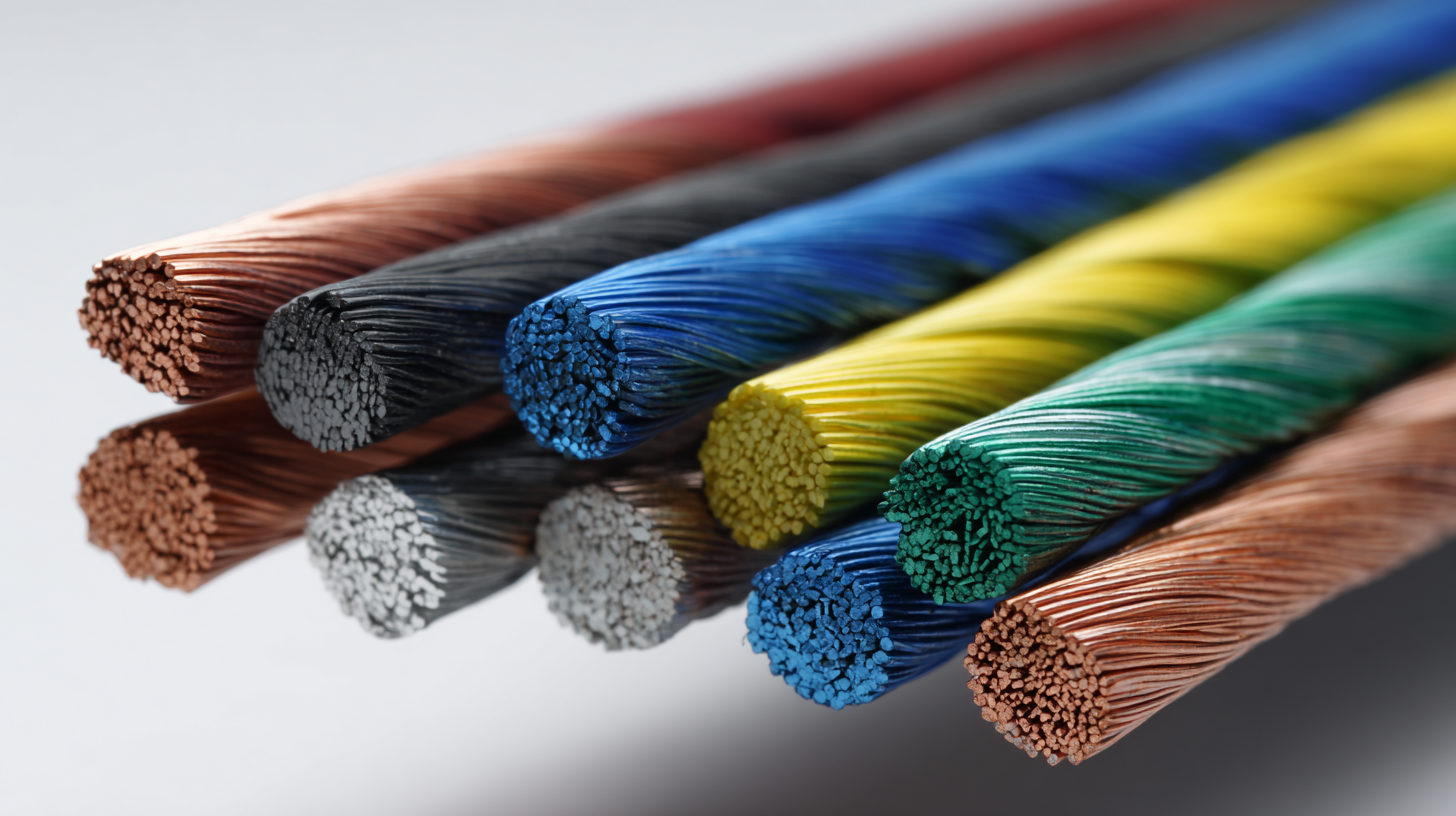

As the demand for electrical efficiency and performance in wire applications continues to rise, the comparison between copper and aluminum conductors has become increasingly significant. Copper's superior conductivity and durability make it a traditional choice for many electrical applications. However, aluminum's light weight and cost-effectiveness are driving its adoption in industries such as automotive and renewable energy, where sustainability is a growing focus.

Tips for those considering conductor materials include evaluating the specific requirements of your project, such as voltage, weight constraints, and environmental conditions. Aluminum may be ideal for low-voltage applications with rigorous weight restrictions, while copper might be more suitable for high-performance needs.

Furthermore, incorporating aluminum wiring harnesses in automobiles not only reduces weight but also contributes to improved fuel efficiency. As the industry shifts toward more sustainable practices, understanding the advantages and limitations of each material is essential for informed decision-making.

The choice of wire gauge is critical in optimizing electrical efficiency and performance, as it directly affects electrical resistance. According to industry studies, a lower gauge number indicates a thicker wire, leading to reduced resistance and increased current-carrying capacity. For instance, using a 12-gauge wire instead of a 14-gauge wire can improve efficiency by up to 20% in certain applications, minimizing energy losses associated with heat dissipation. This is particularly important in high-demand environments, where every percentage point of efficiency can translate into significant energy savings.

When examining the impact of wire gauge on electrical systems, it is essential to consider not only resistance but also the wire's thermodynamic properties. Research shows that wires with a smaller gauge produce less heat due to lower resistance, and this can enhance the longevity and reliability of electrical connections. For example, the National Electrical Code suggests that utilizing a thicker wire can prevent overheating, which is a common failure point in electrical systems, especially in applications like renewable energy setups or high-performance industrial machinery. This balancing act between wire gauge, resistance, and performance is foundational for achieving optimal system efficiency.

In the quest for electrical efficiency and performance, the integration of innovative coatings and insulations is essential. As industries recognize the paramount importance of enhancing the durability and functionality of single conductor wires, several advancements are emerging. For instance, the global smart coatings market is anticipated to grow from $8.34 billion in 2025 to $26.15 billion by 2032, reflecting a compound annual growth rate (CAGR) of 17.7%. This boom is driven by the increasing demand for high-performance materials capable of withstanding extreme conditions while ensuring optimal electrical conductivity.

One of the notable trends includes the adoption of advanced thermal barrier coatings, projected to grow from USD 18.7 billion in 2025 to USD 29.0 billion by 2035. These coatings offer enhanced protection against thermal fluctuations, making them ideal for applications in environments subject to high stress. Additionally, the silicone recycling market is gaining traction, underscoring a growing emphasis on sustainability within the industry.

**Tips:**

- When selecting wire coatings, consider materials that offer both thermal protection and electrical insulation for enhanced performance.

- Keep an eye on emerging innovations in silicone surfactants, as these can provide significant advantages in wire applications, improving efficiency while contributing to sustainability efforts.

The trend towards energy optimization in single conductor wire technology is rapidly evolving, driven by advancements in materials and manufacturing processes. According to a 2023 market report from Technavio, the global single conductor wire market is projected to grow by over 6% CAGR by 2025, attributed to the increasing demand for energy-efficient electrical systems. This growth highlights the critical need for manufacturers to innovate their wire technologies to enhance conductivity while minimizing energy losses.

Recent developments in conductor materials, such as copper-clad aluminum and advanced composite wires, offer significant advantages in terms of weight and performance. A study by the International Energy Agency (IEA) noted that using these materials can reduce resistive losses in electrical systems by up to 30%, making them a compelling choice for future applications in renewable energy and electric vehicles. As we look towards 2025, it is clear that the integration of advanced technologies, such as nanotechnology in conductor coatings and the use of artificial intelligence in wire design, will further optimize energy efficiency, setting new industry standards for performance and sustainability.