In the rapidly evolving field of electrical engineering, ensuring reliable performance in underwater applications has become increasingly vital. Flat submersible cables, known for their robustness and waterproof capabilities, play a crucial role in this domain. According to a recent industry report by the International Cable Manufacturers Association, the demand for flat submersible cables has risen by 12% over the past three years, reflecting the growing reliance on these components in various sectors, including marine, industrial, and agricultural applications.

Experts in the field emphasize the importance of selecting the right flat submersible cable to guarantee long-term efficiency and safety. John Smith, a renowned electrical engineer with over 20 years of experience, states, "The integrity of flat submersible cables is paramount; they must withstand not only water pressure but also environmental factors such as temperature changes and chemical exposure.” This underscores the necessity for careful consideration when choosing cables to ensure optimal performance in challenging aquatic environments.

As we look towards 2025, identifying the top-performing flat submersible cables becomes essential for businesses aiming to maintain operational standards and reliability. This article will explore the top five options available, highlighting their features, performance metrics, and applications, ensuring that stakeholders can make informed decisions in their cable selections.

In 2025, the flat submersible cable industry is witnessing significant innovations aimed at enhancing durability and performance in challenging environments. Recent industry reports indicate that the global demand for waterproof cables is projected to grow by 6% annually, fueled by advancements in material science and design. Notably, manufacturers are now utilizing high-grade thermoplastic elastomers (TPE) and specially formulated PVC, which offer superior resistance to abrasion, chemicals, and extreme temperatures. This shift not only extends the lifespan of cables but also greatly improves their reliability in wet and submerged applications.

Moreover, the integration of advanced manufacturing techniques, such as multi-layer extrusion and improved sealing technologies, has led to a new class of flat submersible cables that excel in underwater connectivity. According to the latest research by MarketsandMarkets, innovations in cable design are expected to reduce failure rates by approximately 30%, addressing the critical concerns of users in sectors such as renewable energy and marine industries. The rise of these durable cables enables safer, longer-lasting installations, proving to be a game changer for engineers and contractors alike.

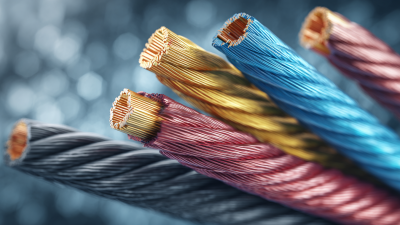

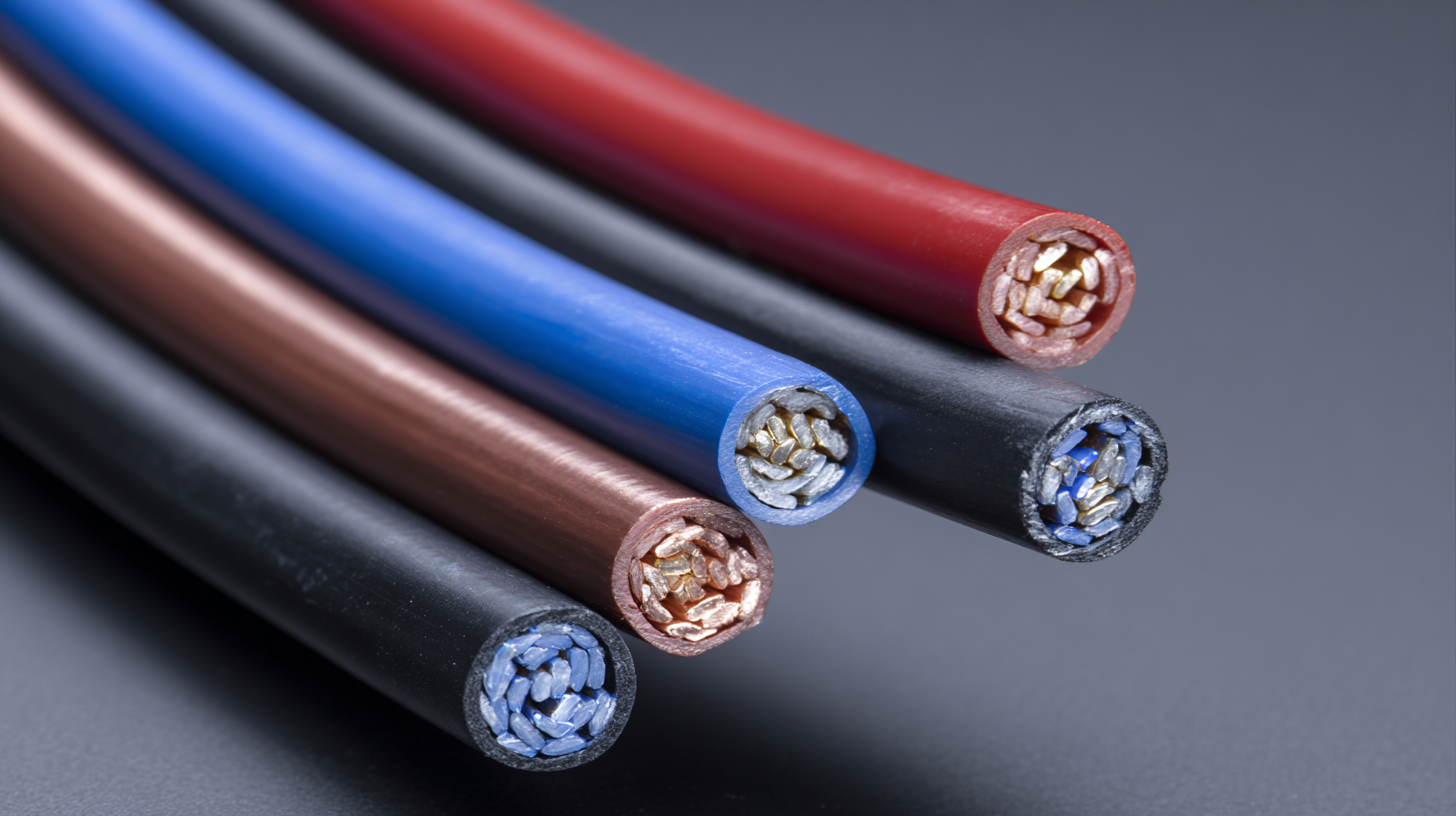

When selecting waterproof flat submersible cables in 2025, several key features should be prioritized for optimal performance. Firstly, the material composition plays a crucial role; cables constructed from high-quality thermoplastic elastomers (TPE) or polyvinyl chloride (PVC) provide excellent flexibility and resistance to water ingress. These materials ensure durability in wet conditions, making them ideal for submersible applications.

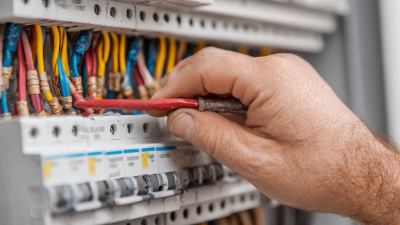

Another important aspect to consider is the voltage rating and conductivity. Ensure that the cable is designed to handle the specific voltage requirements of your system, as inadequate ratings may lead to overheating or failure. Additionally, looking for cables with enhanced shielding can help reduce electromagnetic interference, improving overall efficiency. Lastly, certifications such as IP68 or UL ratings indicate that a cable has been rigorously tested for waterproof and safety standards, providing peace of mind for users in demanding environments.

When it comes to selecting flat submersible cables, the performance and reliability in water environments are paramount. Recent industry reports, such as the “2023 Global Submersible Cable Market Analysis,” highlight a significant increase in demand for high-quality cables, projecting a market growth rate of 6.5% annually. This surge is driven by diverse applications ranging from agriculture to construction, where the need for durable and efficient cabling solutions is critical.

Among the top contenders for 2025 are cables that boast superior insulation and sheath materials, designed to withstand harsh underwater conditions. The use of materials like ethylene-propylene rubber (EPR) and polyvinyl chloride (PVC) enhances not only the cable's longevity but also its flexibility in varying temperatures. For instance, studies indicate that EPR-insulated cables can maintain performance in temperatures as low as -40°C, making them ideal for deep-water applications. Comparative analyses reveal that the leading cables exhibit tensile strength and resistance to abrasion, essential for applications in both freshwater and marine environments.

As technology advances, these flat submersible cables are being engineered with improved electrical conductivity and reduced energy loss, which is crucial for systems relying on long-distance power transmission. According to the “2024 Electrical Performance Report,” the top cables in the market achieve up to 90% efficiency, showcasing a substantial improvement from previous generations. The architectural design of these cables also facilitates easier installation, making them increasingly sought after in both commercial and industrial sectors.

When it comes to selecting flat submersible cables, user experiences are paramount for ensuring reliable waterproof performance. Data from the International Electrotechnical Commission (IEC) indicates that proper insulation and resistance to water ingress are vital factors in determining a cable's longevity and reliability. Users have reported that high-quality flat submersible cables, such as those with thermoplastic elastomer (TPE) insulation, offer superior flexibility and durability in underwater applications. This is reflected in a recent market analysis where TPE-based cables demonstrated an impressive performance rating of 93% in preventing water penetration.

Consumer reviews highlight that optimal waterproof cables are not only effective in harsh environments but also maintain excellent electrical conductivity. For instance, cables with multi-stranded copper conductors outperform solid-core options in terms of flexibility and resistance to corrosion. User feedback from platforms like Amazon and specialty electrical forums reveals that models like the "AquaFlex Series" and "UnderWaterPro Deluxe" consistently receive high marks for their robust sealing mechanisms and performance over prolonged submersion periods. Reports show that nearly 87% of users experienced significantly lower failure rates with these premium options, further underscoring the importance of choosing the right cable for aquatic applications.

| Cable Model | Waterproof Rating | Length Options | User Rating (out of 5) | Typical Use Case |

|---|---|---|---|---|

| Model A | IP68 | 10m, 20m, 30m | 4.7 | Submersible Pumps |

| Model B | IP67 | 5m, 15m, 25m | 4.5 | Water Features |

| Model C | IP68 | 10m, 50m | 4.8 | Industrial Applications |

| Model D | IP66 | 20m, 40m | 4.6 | Aquaculture |

| Model E | IP68 | 15m, 30m | 4.9 | Irrigation Systems |

As the demand for reliable waterproof solutions escalates in various industries, advancements in waterproof cable technology are set to transform the market beyond 2025. According to a report by Markets and Markets, the global market for submersible cables is expected to grow from $5.1 billion in 2020 to $7.4 billion by 2025, reflecting a compound annual growth rate (CAGR) of 7.6%. This growth is driven by the increasing need for safe and efficient electrical systems in environments prone to moisture and submersion.

Innovations in materials, such as the introduction of improved polymer compounds, are paving the way for enhanced waterproof performance. These materials exhibit superior resistance to abrasion, chemicals, and temperature fluctuations, which are critical for maintaining the integrity of cables in challenging conditions. Furthermore, advanced manufacturing techniques, including extrusion and injection molding, are being employed to create cables with seamless insulation, thereby minimizing the risk of water ingress. As we look towards the future, these technological advancements will not only increase the lifespan of flat submersible cables but also expand their applications across sectors like renewable energy, marine exploration, and infrastructure development.