Three Phase Armoured Cable plays a crucial role in modern electrical systems. It provides durability and safety in power distribution, making it essential for various industries. According to industry expert Mark Thompson, "Three Phase Armoured Cable ensures reliable performance and resistance against harsh environments." This underscores its importance in several applications.

In today’s world, the demand for efficient electrical solutions continues to grow. Three Phase Armoured Cable offers advantages that cannot be overlooked. Its robust design not only protects against mechanical damage but also withstands moisture and chemical exposure. These features contribute to a longer lifespan for electrical installations, reducing maintenance costs over time.

However, it's important to acknowledge that not all installations are perfect. Some users may overlook proper installation techniques, which can lead to suboptimal performance. Reflecting on this, one must consider both the benefits and potential mishaps in the wiring process. Despite these challenges, the overall advantages of Three Phase Armoured Cable vastly outweigh its drawbacks.

Three-phase armoured cable is essential in industrial and commercial settings. It provides robust power distribution and communication. This cable type is highly durable, designed for harsh environments. It can withstand mechanical stresses and weather impacts. A report by the International Electrotechnical Commission notes that the global demand for three-phase power systems is growing at around 7% annually.

These cables consist of three insulated conductors and a protective metallic sheath. This design ensures enhanced safety and lower electrical losses. Armoured cables are crucial for minimizing downtime in production areas. They are less prone to damage from rodents and environmental factors. A survey of installation sectors highlights that using armoured cables can reduce maintenance costs by 30%.

**Tip:** Always inspect armoured cables for signs of wear or damage. Regular checks can prevent serious electrical failures and accidents.

Three-phase armoured cables also allow for higher efficiency. They facilitate balanced load distribution, leading to better energy management. However, they can be more challenging to install. The weight and rigidity require skilled technicians for proper handling. Additionally, incorrect installation could undermine the benefits they provide.

**Tip:** Ensure that your installation team is well-trained. This can avoid costly mistakes and ensure safety.

| Advantage | Description |

|---|---|

| Increased Efficiency | Three phase systems provide a more stable and efficient power supply compared to single phase systems. |

| Higher Power Capacity | Allows for the transmission of more power without requiring larger conductors. |

| Reduced Voltage Drop | Less voltage drop over extended distances compared to single phase cable. |

| Improved Load Distribution | Distributes electric loads evenly across three phases, balancing the system. |

| Durable Construction | Armoured cables offer enhanced protection against mechanical damage. |

| Reduced Flicker | Minimizes light flicker in lighting applications, improving comfort and productivity. |

| Versatility | Suitable for various applications, including industrial, commercial, and residential. |

| Longer Lifespan | Typically lasts longer due to superior materials and construction methods. |

| Easier Installation | Streamlined installation processes for contractors and electricians. |

| Cost-Effective | Although initial costs may be higher, operational savings make them cost-effective in the long run. |

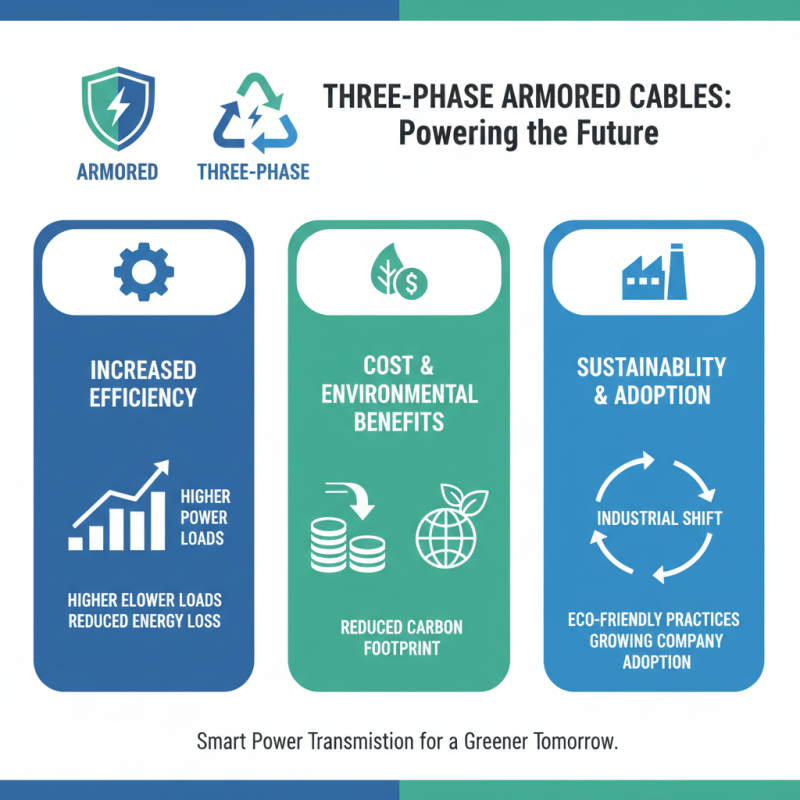

Three-phase armoured cables offer several benefits, especially in terms of electrical efficiency. These cables are designed to handle higher power loads. They reduce energy loss during transmission. This efficiency means lower electricity bills and reduced environmental impact. More companies turn to three-phase options for sustainable practices.

A significant advantage is the lower voltage drop. This drop is often an issue in single-phase systems. With three-phase cables, the power delivered is consistent and reliable. This reliability leads to more stable operations in industrial applications. Businesses can rely on their machinery, reducing downtime.

Tips: When selecting three-phase cables, ensure they meet your specific power requirements. Consider installation environment factors. Always consult with an expert for optimal performance.

However, some users may overlook installation quality. Poor installation can negate the efficiency benefits. Always prioritize skilled technicians for installation. Small details can lead to significant differences in performance over time.

Three-phase armoured cables are designed to withstand harsh environments. They have a robust construction that protects them from physical damage. Their durability is critical in industrial settings where exposure to chemicals and moisture is common. A study by the International Electrotechnical Commission notes that armoured cables can endure adverse conditions better than standard cables.

The armouring of these cables enhances their resistance to mechanical stress. For example, they can resist impacts and abrasions, making them suitable for outdoor and underground installations. This feature is particularly important in construction and mining sectors, where wear and tear can lead to costly failures. Reports indicate that 70% of cable failures occur due to external damage.

Moreover, armoured cables are more resistant to temperature fluctuations. They maintain performance in extreme conditions, whether hot or cold. This reliability is crucial for applications in regions with harsh weather. Yet, it's important to assess the installation environment carefully. While these cables offer many advantages, improper installation could undermine their benefits. Proper training and knowledge about handling are essential for maximizing their lifespan.

Three phase armoured cables are designed with robust safety features. They often have an extra layer of protection that safeguards against physical damage. This is essential in industrial settings where equipment is subject to harsh conditions. Whether it's extreme temperatures or moisture, the armoured layer provides reliable defense.

Moreover, the cable's design helps minimize the risk of electrical hazards. The protective sheathing prevents wear and tear from environmental elements. In areas with heavy machinery, this becomes crucial. A damaged cable can lead to serious incidents. However, it's important to regularly inspect these cables for any signs of damage. Over time, even the most resilient materials may wear down.

While three phase armoured cables offer enhanced safety, proper installation is vital. An improperly installed cable can negate all safety protections. It's essential to follow best practices during installation. Training personnel and conducting thorough checks can prevent potential failures. Relying solely on the cable's features without due diligence can be a critical oversight.

Three-phase armoured cables offer significant cost-effectiveness and long-term investment benefits. According to industry reports, they reduce energy losses by up to 30% compared to single-phase systems. This efficiency translates into lower electricity bills. Over time, the savings accumulate and offset the initial installation costs.

Using these cables can also decrease maintenance expenses. Their durable armoured design protects them from physical damage. A study shows that businesses spend 15% less on repairs with three-phase systems. This can enhance the overall budgeting for projects, making it more predictable.

Tip: Always consider the total cost of ownership. This includes installation, maintenance, and energy consumption.

Investing in three-phase armoured cables is strategic. They have a longer lifespan than traditional cables. Some estimates suggest they last up to 40% longer. While the upfront cost might be higher, the return on investment is notable. It encourages users to reflect on their choices for future installations.

Tip: Look for quality certifications to ensure reliability. Safety and durability should be top priorities.