In the ever-evolving landscape of electrical engineering, understanding the intricacies of Mv Cables Specifications is paramount for professionals seeking to optimize their systems and ensure safety in operations. Medium voltage cables are critical components that facilitate power distribution and transmission, yet many electrical professionals struggle to navigate the vast array of specifications and standards associated with these essential elements. This comprehensive guide aims to demystify Mv Cables Specifications, offering insights into key characteristics such as insulation types, conductor materials, voltage ratings, and environmental considerations. By delving into these specifications, electrical professionals can enhance their expertise, make informed decisions for installations, and ultimately contribute to the reliability and efficiency of electrical systems in various applications. This introduction sets the stage for a thorough exploration of the subject, equipping readers with the knowledge needed to excel in their electrical endeavors.

When selecting medium voltage (MV) cables, understanding the various types available and their specific application scenarios is crucial for electrical professionals. MV cables are generally categorized into types such as XLPE (cross-linked polyethylene), PVC (polyvinyl chloride), and EPR (ethylene propylene rubber), each offering distinct advantages. According to a recent report by Research and Markets, the global medium voltage cable market is projected to grow at a CAGR of 7.74% from 2021 to 2026, reflecting the increasing demand for efficient energy distribution systems across industries.

The selection criteria for MV cables hinge upon several factors including the operating environment, installation conditions, and electrical performance requirements. For instance, XLPE cables are praised for their excellent insulation properties and thermal resistance, making them ideal for outdoor applications and in areas exposed to harsh weather conditions. Conversely, PVC cables may be preferred in controlled environments due to their cost-effectiveness and ease of handling. The 2021 Electrical Industry Report indicates that around 60% of MV cable failures arise from improper installation or selection, highlighting the importance of selecting the right cable type for specific scenarios to enhance longevity and reliability.

When selecting medium voltage (Mv) cables, it is crucial to understand their key specifications, particularly voltage ratings, conductors, and insulation materials.

Voltage ratings indicate the maximum voltage that a cable can safely handle without risk of failure. It is essential for electrical professionals to choose cables that can accommodate the specific voltage requirements of their projects to ensure both safety and efficiency.

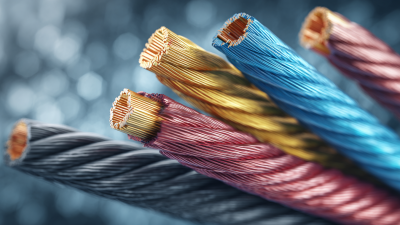

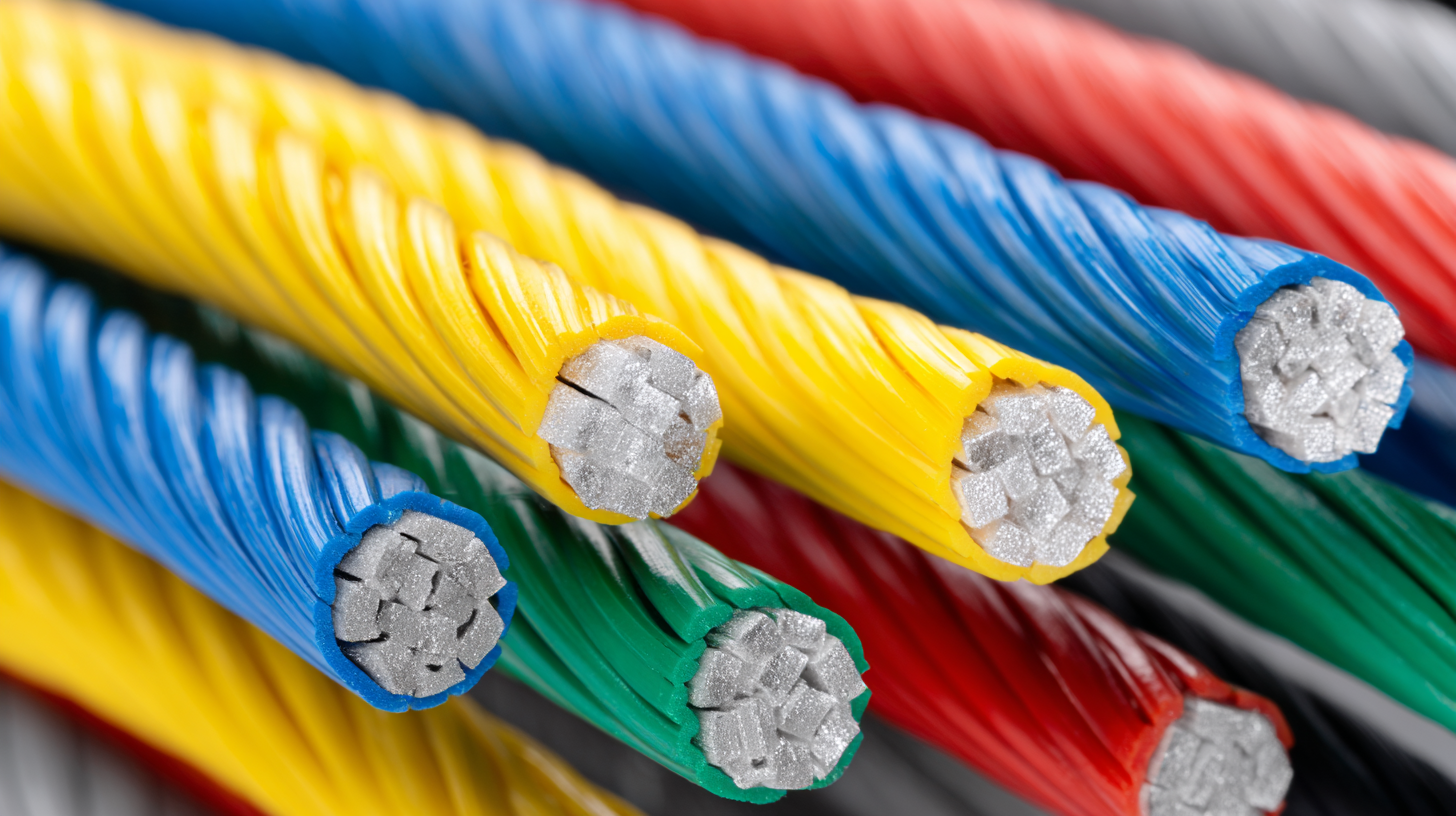

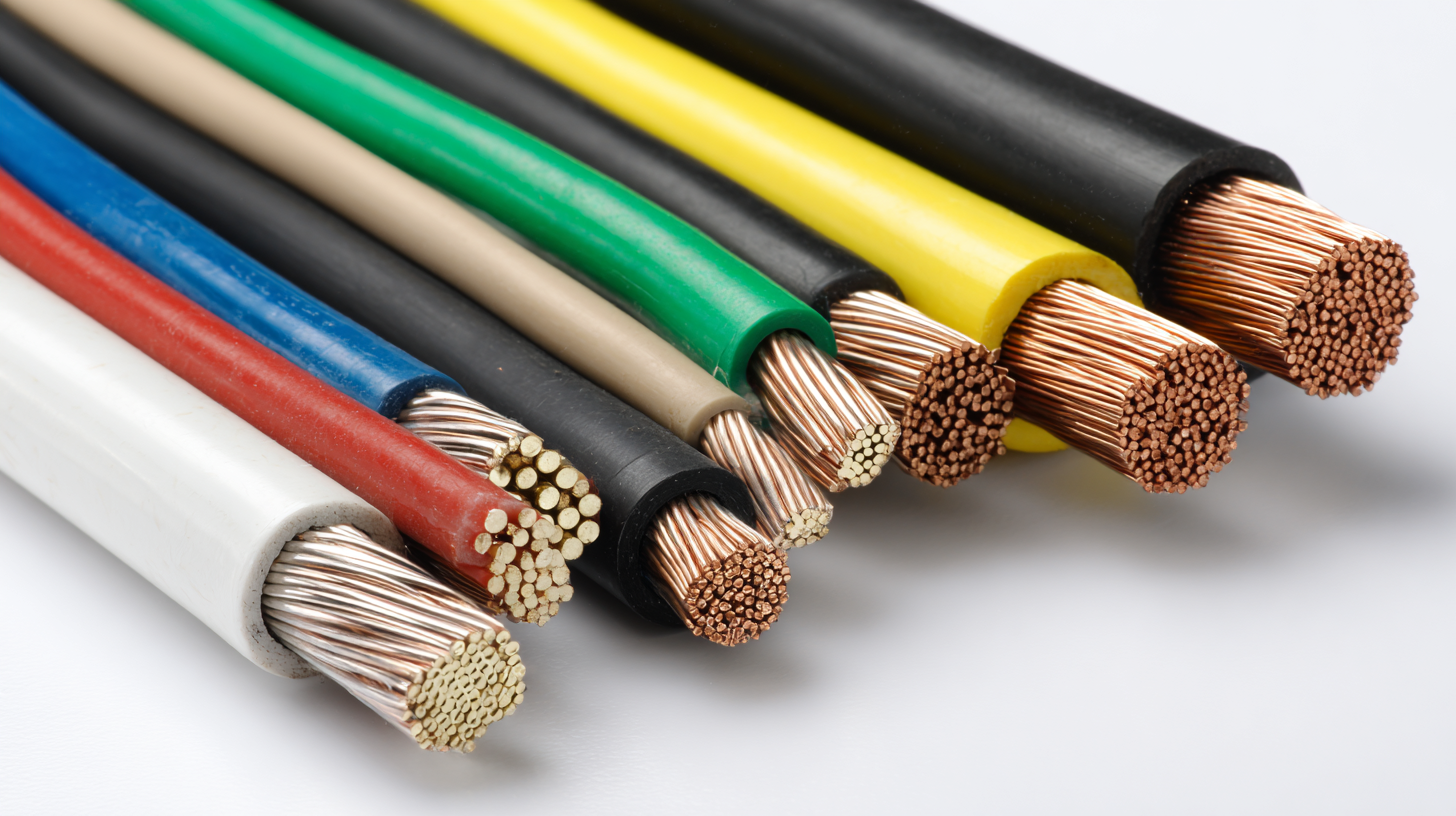

Conductors play a vital role in the performance of Mv cables. They can be made from copper or aluminum, with copper being the preferred choice for its superior conductivity and corrosion resistance. The size and type of conductor must be selected based on the load requirements and environmental factors.

Additionally, consider the temperature rating of the conductor materials to prevent overheating and ensure reliable operation.

Tip: Always refer to local regulations and industry standards when selecting Mv cables to ensure compliance and safety.

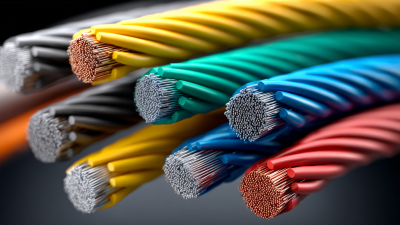

The insulation materials used in Mv cables also significantly impact their performance. Common insulation types include XLPE (cross-linked polyethylene) and PVC (polyvinyl chloride), each offering distinct benefits.

For example, XLPE provides excellent thermal resistance and mechanical strength, making it suitable for high-performance applications. When selecting insulation, consider factors such as environmental conditions, installation methods, and mechanical stresses that the cables may face.

Tip: Perform regular checks on cable insulation to identify wear and tear, as this can help prevent costly failures and enhance the longevity of the installation.

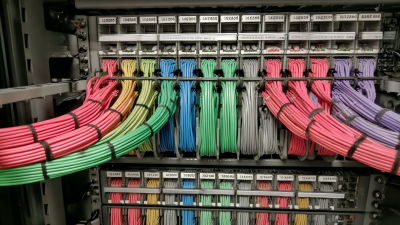

When it comes to the installation of medium voltage (MV) cables, understanding the best practices is crucial for ensuring safety and efficiency. According to the IEEE 400.1 standard, proper installation practices can reduce the likelihood of cable failures caused by environmental factors or mechanical stress. Electrical professionals should prioritize rigorous testing during the installation phase, specifically insulation resistance and continuity tests. Research indicates that approximately 30% of MV cable failures occur within the first five years due to improper installation techniques or inadequate environmental considerations.

In addition, adhering to manufacturer's specifications and local regulatory requirements plays a significant role in the successful deployment of MV cables. The National Electrical Code (NEC) outlines necessary guidelines for cable routing, spacing, and protective measures. Current reports from the International Electrotechnical Commission (IEC) highlight that inappropriate installation practices can lead to increased thermal stress, which is a major contributor to cable insulation degradation over time. By implementing best practices, such as using proper cable trays and ensuring adequate conductor clearance, electrical professionals not only extend the lifespan of the cable system but also enhance overall system reliability.

Testing and maintenance procedures for medium voltage (MV) cables are crucial to ensuring their reliability and safety in electrical systems. According to a report from the International Electrotechnical Commission (IEC), up to 30% of MV cable failures can be attributed to insulation degradation, which can occur over time due to environmental conditions and electrical stresses. Routine testing techniques, such as insulation resistance testing and partial discharge measurements, allow professionals to detect early signs of deterioration and prevent potential failures. Incorporating these tests into scheduled maintenance can substantially increase the lifespan of the cables and minimize unplanned outages.

In addition to testing, physical inspections should be conducted regularly to identify any signs of mechanical damage or external threats such as moisture intrusion and rodent activity. The IEEE Power and Energy Society suggests implementing a predictive maintenance strategy that combines testing results with historical performance data, providing a comprehensive understanding of each cable's condition. This proactive approach not only enhances safety by minimizing the risk of catastrophic failures but also optimizes maintenance schedules, ensuring that resources are effectively allocated. By adhering to these practices, electrical professionals can maintain the integrity of MV cables and uphold the operational reliability of power systems.

In the rapidly evolving landscape of electrical engineering, Medium Voltage (MV) cables play a crucial role, necessitating a thorough understanding of regulatory standards and compliance. Industry reports indicate that adherence to specific regulations, such as IEC 60502 and ANSI/ICEA S-94-649, is essential for ensuring the safety and reliability of electrical installations. These standards define the technical specifications for MV cables, including insulation types, temperature ratings, and installation methods, which significantly impact overall system performance.

Moreover, compliance with local and international regulatory frameworks is vital for electrical professionals. For instance, the National Electric Code (NEC) in the United States mandates specific requirements for MV cables used in various applications, ensuring they can withstand environmental stresses and operational demands. According to a 2022 market analysis by Research and Markets, the global MV cable market is expected to grow from $30 billion to over $45 billion by 2027, driven by increasing investments in renewable energy and infrastructure development. Understanding these compliance standards not only mitigates risks but also enhances the integrity of electrical systems, ultimately leading to safer and more efficient energy distribution.