600/1000V XLPE Insulated and Lead Sheathed Cables according to IEC 60502-1

Applicatio of Lead Sheathed Cables

These cables are utilised for the transmission of electricity within low-voltage installation systems. Their suitability for installation extends to both indoor and outdoor environments, including cable ducts, subterranean settings, power and switching stations, local energy distribution networks, and industrial facilities, provided there is an absence of risk of mechanical damage. The lead sheath has been shown to provide enhanced resistance to aromatic hydrocarbons.

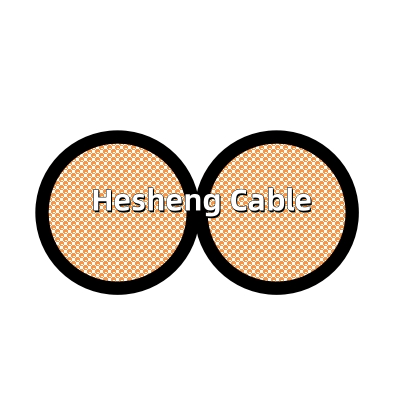

Construction of Lead Sheathed Cables

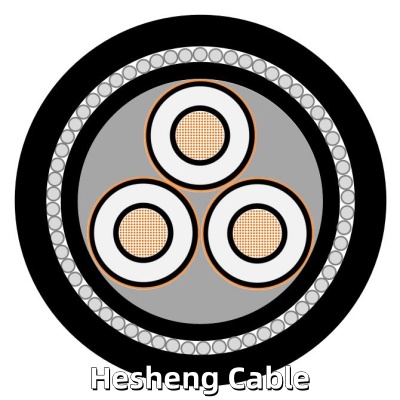

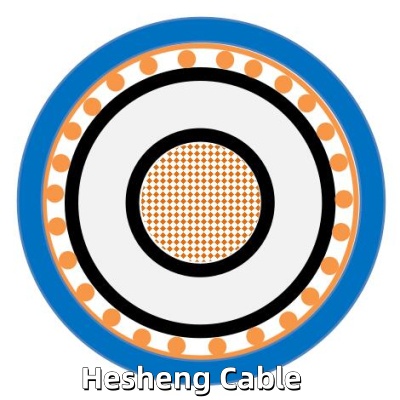

Conductors

The conductors shall be either of Class 1 or Class 2 of plain or metal-coated annealed copper or of plain aluminium or aluminium alloy, or of Class 5 of plain or metal-coated copper in accordance with IEC 60228.

Insulation

XLPE material and thickness shall be as per IEC 60502-1, rated for 90°C continuous operation.

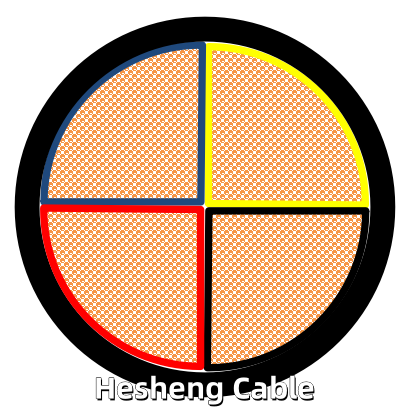

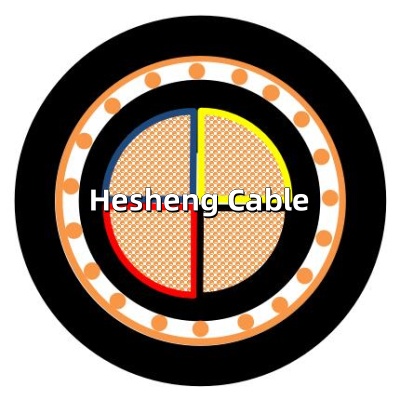

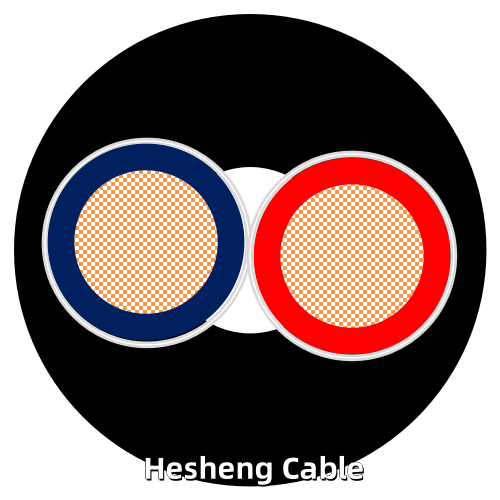

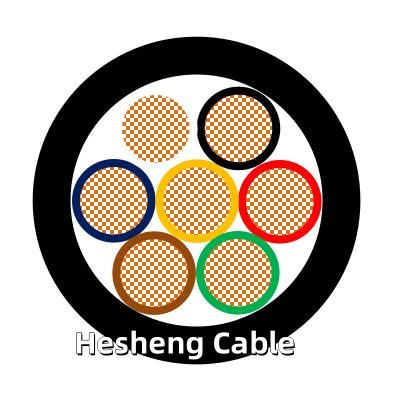

Colour Code

Colour Code (1)

1 Core Red or Black

2 Cores Red, Black

3 Cores Red, Yellow, Blue

4 Cores Red, Yellow, Blue, Black

5 Cores Red, Yellow, Blue, Black, Green

Above 5 Cores Black Cores with White numerals

Colour Code (2)

1 Core Brown or Blue

2 Cores Brown, Blue

3 Cores Brown, Black, Grey

4 Cores Blue, Brown, Black, Grey

5 Cores Green/Yellow, Blue, Brown, Black, Grey

Above 5 Cores Black Cores with White numerals

Other colours can be manufactured upon request.

Assembly / Inner Covering

The inner coverings can be extruded or lapped. For cables with circular cores, except cables with more than five cores, a lapped inner covering is allowed only if the spaces between the cores are mostly filled. You can use a suitable binder before you put on the extruded inner covering. The material works well with the insulating material.

The materials used for inner coverings and fillers must be able to handle the cable's operating temperature and must also work well with the insulating material.

For halogen-free cables, the inner coverings and fillers must be made of halogen-free compounds.

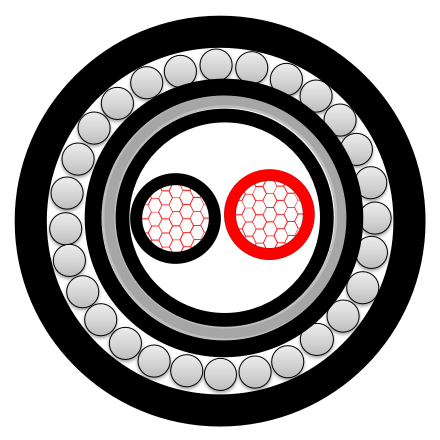

Lead Sheath

lead or lead alloy and shall be applied as a reasonably tight-fitting seamless tube.

Seperation Sheath

The seperation sheath shall be of extruded PVC Type ST2 as per IEC 60502-1, or other material refer to outer sheath material.

Armour

Aluminum/galvanized steel/steel wires applied helically over the Inner Covering as per IEC 60502-1, or double aluminum/steel tapes and copper/tinned copper wire can also be manufactured upon request.

Outer Sheath

Outer sheath shall be of extruded PVC Type ST1/ST2 as per IEC 60502-1, Polyethylene type ST3/ST7, Halogen free compound ST8, Polychloroprene, chlorosulfonated polyethylene or similar polymers, type SE1 are also available on request.

Technical Parameters

| Nominal Cross Section | Diameter of Conductor (Approx.) | Nominal Insulation Thickness | Nominal Lead Sheath Thickness | Nominal Sheath Thickness | Overall Diameter (Approx.) | Nominal Cross Section | Diameter of Conductor (Approx.) | Nominal Insulation Thickness | Nominal Lead Sheath Thickness | Nominal Sheath Thickness | Overall Diameter (Approx.) |

| mm^2 | mm | mm | mm | mm | mm | mm^2 | mm | mm | mm | mm | mm |

| 1x35 | 6.7 | 0.9 | 1.2 | 1.5 | 15.8 | 1x35 | 7.4 | 1.2 | 1.2 | 1.8 | 16.6 |

| 1x50 | 8 | 1 | 1.2 | 1.5 | 17.4 | 1x50 | 8.8 | 1.4 | 1.2 | 1.8 | 18.8 |

| 1x70 | 9.4 | 1.1 | 1.2 | 1.6 | 19.1 | 1x70 | 10.6 | 1.4 | 1.2 | 1.8 | 20.4 |

| 1x95 | 11 | 1.1 | 1.3 | 1.6 | 21 | 1x95 | 12.4 | 1.6 | 1.3 | 1.8 | 22 |

| 1x120 | 12.4 | 1.2 | 1.3 | 1.7 | 22.8 | 1x120 | 14 | 1.6 | 1.3 | 1.8 | 23.6 |

| 1x150 | 13.8 | 1.4 | 1.4 | 1.7 | 24.8 | 1x150 | 15.5 | 1.8 | 1.4 | 1.8 | 25.4 |

| 1x185 | 15.3 | 1.6 | 1.4 | 1.8 | 27 | 1x185 | 17.4 | 2 | 1.4 | 1.9 | 28.2 |

| 1x240 | 17.5 | 1.7 | 1.5 | 1.9 | 29.7 | 1x240 | 20.3 | 2.2 | 1.5 | 1.9 | 30.8 |

| 1x300 | 19.5 | 1.8 | 1.6 | 2 | 32.2 | 1x300 | 22.7 | 2.4 | 1.6 | 2 | 33.1 |

| 1x400 | 22.6 | 2 | 1.7 | 2.1 | 36.6 | 1x400 | 25.4 | 2.6 | 1.7 | 2.2 | 37.3 |

| 1x500 | 25.2 | 2.2 | 1.8 | 2.2 | 40 | 1x500 | 28.8 | 2.8 | 1.8 | 2.3 | 41.6 |

| 1x630 | 28.3 | 2.4 | 1.9 | 2.4 | 44 | 1x630 | 30.4 | 2.8 | 1.9 | 2.4 | 45.3 |

| 2x2.5 | 1.8 | 0.7 | 1.2 | 1.8 | 14.4 | 2x2.5 | 1.8 | 0.7 | 1.2 | 1.8 | 14.5 |

| 2x4 | 2.3 | 0.7 | 1.2 | 1.8 | 15.4 | 2x4 | 2.3 | 0.7 | 1.2 | 1.8 | 15.5 |

| 2x6 | 2.8 | 0.7 | 1.2 | 1.8 | 16.4 | 2x6 | 2.8 | 0.7 | 1.2 | 1.8 | 16.5 |

| 2x10 | 3.6 | 0.7 | 1.2 | 1.8 | 18 | 2x10 | 3.6 | 0.7 | 1.2 | 1.8 | 18.8 |

| 2x16 | 4.5 | 0.7 | 1.2 | 1.8 | 19.8 | 2x16 | 4.5 | 0.7 | 1.2 | 1.8 | 20.6 |

| 2x25 | 5.6 | 0.9 | 1.2 | 1.8 | 22.8 | 2x25 | 5.6 | 0.9 | 1.2 | 1.8 | 23.6 |

| 2x35 | 6.7 | 0.9 | 1.3 | 1.8 | 25.1 | 2x35 | 6.7 | 0.9 | 1.3 | 1.8 | 25.8 |

| 2x50 | 8 | 1 | 1.4 | 1.9 | 28.5 | 2x50 | 8 | 1 | 1.4 | 1.9 | 29.8 |

| 2x70 | 9.4 | 1.1 | 1.5 | 2 | 32.1 | 2x70 | 9.4 | 1.1 | 1.5 | 2 | 33.2 |

| 2x95 | 11 | 1.1 | 1.6 | 2.1 | 36.2 | 2x95 | 11 | 1.1 | 1.6 | 2.1 | 37.1 |

| 2x120 | 12.4 | 1.2 | 1.7 | 2.2 | 39.8 | 2x120 | 12.4 | 1.2 | 1.7 | 2.3 | 41.6 |

| 2x150 | 13.8 | 1.4 | 1.8 | 2.4 | 43.9 | 2x150 | 13.8 | 1.4 | 1.8 | 2.4 | 45.4 |

| 2x185 | 15.3 | 1.6 | 1.9 | 2.5 | 48.6 | 2x185 | 15.3 | 1.6 | 1.9 | 2.6 | 49.9 |

| 2x240 | 17.5 | 1.7 | 2 | 2.7 | 54.1 | 2x240 | 17.5 | 1.7 | 2 | 2.7 | 55.1 |

| 2x300 | 19.5 | 1.8 | 2.2 | 2.9 | 59.5 | 2x300 | 19.5 | 1.8 | 2.2 | 2.9 | 60.2 |

| 3x1.5 | 1.4 | 0.7 | 1.2 | 1.8 | 14 | 3x1.5 | 1.4 | 0.7 | 1.2 | 1.8 | 14.1 |

| 3x2.5 | 1.8 | 0.7 | 1.2 | 1.8 | 14.9 | 3x2.5 | 1.8 | 0.7 | 1.2 | 1.8 | 15 |

| 3x4 | 2.3 | 0.7 | 1.2 | 1.8 | 16 | 3x4 | 2.3 | 0.7 | 1.2 | 1.8 | 16.1 |

| 3x6 | 2.8 | 0.7 | 1.2 | 1.8 | 17 | 3x6 | 2.8 | 0.7 | 1.2 | 1.8 | 17.8 |

| 3x10 | 3.6 | 0.7 | 1.2 | 1.8 | 18.8 | 3x10 | 3.6 | 0.7 | 1.2 | 1.8 | 19.6 |

| 3x16 | 4.5 | 0.7 | 1.2 | 1.8 | 20.7 | 3x16 | 4.5 | 0.7 | 1.2 | 1.8 | 21.5 |

| 3x25 | 5.6 | 0.9 | 1.2 | 1.8 | 24 | 3x25 | 5.6 | 0.9 | 1.2 | 1.8 | 24.7 |

| 3x35 | 6.7 | 0.9 | 1.3 | 1.8 | 26.5 | 3x35 | 6.7 | 0.9 | 1.3 | 1.8 | 27.2 |

| 3x50 | 8 | 1 | 1.4 | 1.9 | 30.2 | 3x50 | 8 | 1 | 1.4 | 2 | 31.5 |

| 3x70 | 9.4 | 1.1 | 1.5 | 2.1 | 34.1 | 3x70 | 9.4 | 1.1 | 1.5 | 2.1 | 35.2 |

| 3x95 | 11 | 1.1 | 1.6 | 2.2 | 38.5 | 3x95 | 11 | 1.1 | 1.6 | 2.3 | 40.3 |

| 3x120 | 12.4 | 1.2 | 1.7 | 2.3 | 42.4 | 3x120 | 12.4 | 1.2 | 1.7 | 2.4 | 44 |

| 3x150 | 13.8 | 1.4 | 1.9 | 2.5 | 47.2 | 3x150 | 13.8 | 1.4 | 1.9 | 2.5 | 48.6 |

| 3x185 | 15.3 | 1.6 | 2 | 2.6 | 51.9 | 3x185 | 15.3 | 1.6 | 2 | 2.7 | 53 |

| 3x240 | 17.5 | 1.7 | 2.1 | 2.8 | 57.7 | 3x240 | 17.5 | 1.7 | 2.1 | 2.8 | 58.5 |

| 3x300 | 19.5 | 1.8 | 2.3 | 3 | 63.6 | 3x300 | 19.5 | 1.8 | 2.3 | 3.1 | 65.4 |

| 4x1.5 | 1.4 | 0.7 | 1.2 | 1.8 | 15.2 | 4x1.5 | 1.4 | 0.7 | 1.2 | 1.8 | 14.9 |

| 4x2.5 | 1.8 | 0.7 | 1.2 | 1.8 | 16.2 | 4x2.5 | 1.8 | 0.7 | 1.2 | 1.8 | 15.8 |

| 4x4 | 2.3 | 0.7 | 1.2 | 1.8 | 18.4 | 4x4 | 2.3 | 0.7 | 1.2 | 1.8 | 17.7 |

| 4x6 | 2.8 | 0.7 | 1.2 | 1.8 | 19.6 | 4x6 | 2.8 | 0.7 | 1.2 | 1.8 | 18.9 |

| 4x10 | 3.6 | 0.7 | 1.2 | 1.8 | 21.5 | 4x10 | 3.6 | 0.7 | 1.2 | 1.8 | 20.9 |

| 4x16 | 4.5 | 0.7 | 1.2 | 1.8 | 23.8 | 4x16 | 4.5 | 0.7 | 1.2 | 1.8 | 23 |

| 4x25 | 5.6 | 0.9 | 1.3 | 1.8 | 27.7 | 4x25 | 5.6 | 0.9 | 1.3 | 1.8 | 26.7 |

| 4x35 | 6.7 | 0.9 | 1.4 | 1.9 | 30.7 | 4x35 | 6.7 | 0.9 | 1.4 | 1.9 | 30.4 |

| 4x50 | 8 | 1 | 1.5 | 2.1 | 35.8 | 4x50 | 8 | 1 | 1.5 | 2.1 | 34.2 |

| 4x70 | 9.4 | 1.1 | 1.6 | 2.2 | 39.6 | 4x70 | 9.4 | 1.1 | 1.6 | 2.2 | 39.9 |

| 4x95 | 11 | 1.1 | 1.7 | 2.4 | 45.1 | 4x95 | 11 | 1.1 | 1.7 | 2.4 | 44 |

| 4x120 | 12.4 | 1.2 | 1.9 | 2.6 | 49.4 | 4x120 | 12.4 | 1.2 | 1.9 | 2.5 | 48.6 |

| 4x150 | 13.8 | 1.4 | 2 | 2.7 | 54.3 | 4x150 | 13.8 | 1.4 | 2 | 2.7 | 53.2 |

| 4x185 | 15.3 | 1.6 | 2.1 | 2.9 | 60 | 4x185 | 15.3 | 1.6 | 2.1 | 2.8 | 58.1 |

| 4x240 | 17.5 | 1.7 | 2.3 | 3.1 | 67.1 | 4x240 | 17.5 | 1.7 | 2.3 | 3.1 | 66.1 |

What is Interlocked Armoured Cable? The Role of Lead Sheathed Cables in Modern Infrastructure

Interlocked armoured cable, commonly known as lead sheathed cable, is a high-performance electrical cable engineered for extreme durability and environmental resistance. Its core design features conductive copper or aluminum conductors insulated with materials like XLPE, surrounded by an interlocked metal armor—typically galvanized steel or lead—that provides unmatched mechanical protection against crushing, abrasion, and moisture. The lead sheath adds a critical layer of impermeability, making these cables ideal for underground, marine, or industrial installations where corrosion resistance and longevity are non-negotiable.

Lead sheathed armored cables excel in harsh environments, including power grids, oil refineries, and offshore wind farms, where exposure to chemicals, water, or temperature fluctuations would degrade standard cables. Their robust construction ensures compliance with IEC and IEEE safety standards, while the lead layer enhances grounding efficiency and fire resistance. Compared to PVC-sheathed alternatives, lead-clad cables offer decades of reliable service with minimal maintenance, reducing lifecycle costs for critical infrastructure.

For engineers prioritizing safety and ROI, lead sheathed cable systems deliver a future-proof solution, blending mechanical resilience with environmental adaptability.

FRQ

|

Who we are? |

|

Hesheng Cable is a excellent electrical cable manufacturer from China with rich production experience since 1998! |

|

|

How to get a exact offer efficiently? |

|

Pls supply the material of conductor, insulation, out sheath!The voltage class? Quantity of each size? |

|

|

Why choose us? |

|

We could produce and supply standard cable or customized as technical parameters supplied by you, Meanwhile, our engineer will try to supply technical supportting if you need... |

|

|

I do not know how to choose cable what I need |

|

Please do not worry. Contact us and send us your requirements, we will help you to choose correct cable you need. If you have below information is better: Cable voltage, conductor material, Insulation and Outer sheath material, armor type. Otherwise you can provide us the cable installation environment, application requirements, etc. |

|

|

What’s your trade term and payment term? |

|

Mostly used trade term is EXW, FOB , CFR/CNF, CIF. Payment term varies from different contract value and commercial clauses. Normally 30% TT advance payment is required, the balance payment by TT / LC . |

|