German Standard Industrial Cables: 0.6/1KV, NYY-J/NYY-O/NAYY-J CU/PVC/PVC Electrical Cable

Application if NYY Electrical Cable

The NYY power cable has been designed for use in a variety of contexts, including cable ducts, power stations, industrial settings, distribution boards, and subscriber networks. It may also be used in brickwork and concrete, with the exception of cabling in shaken, vibrated, or compressed concrete. The NYY cable can be installed in a number of environments, including open air, underground, underwater, and indoors, provided that there is no risk of mechanical damage. The UV resistance allows for outdoor use.

NAYY cables are utilised in a multitude of settings, including power plants, industrial and switching installations, secondary distribution networks, and other applications. These cables are particularly suited to outdoor applications, indoor installations in open air, in the open air, underground, and in water, where the risk of mechanical damage is minimal.

Technical Parameters of NYY Cables

Standard

VDE-0276 Part-603 & Part-627, HD 603.1 & 627 S1, IEC 60502, VDE 0482-332-1-2, DIN EN 60332-1-2 / IEC 60332-1, CE Low Voltage Directive 73/23/EEC and 93/68/EEC,

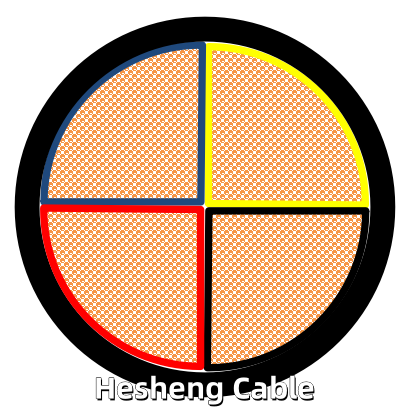

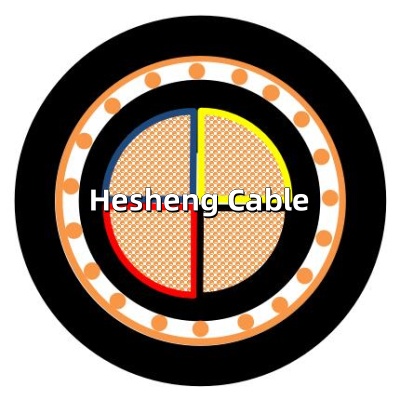

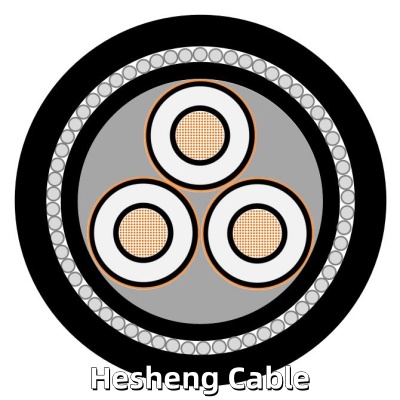

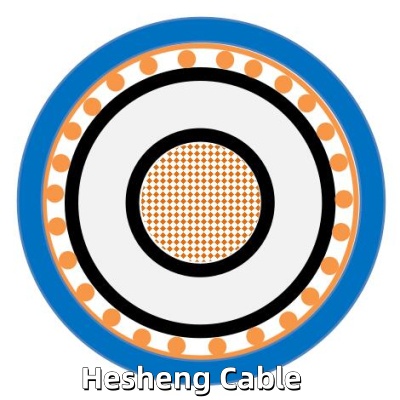

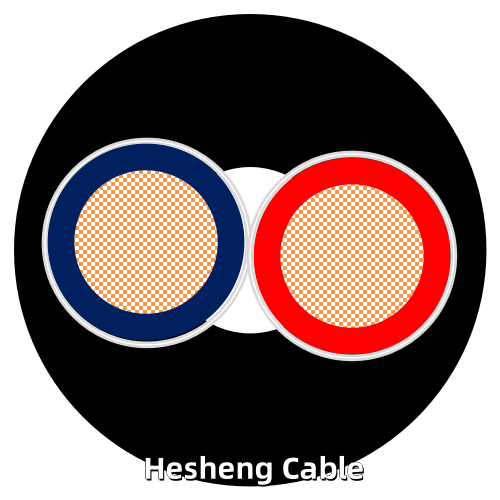

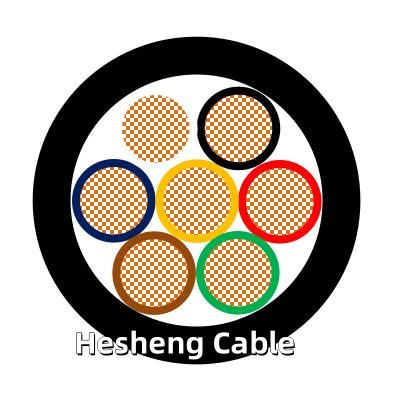

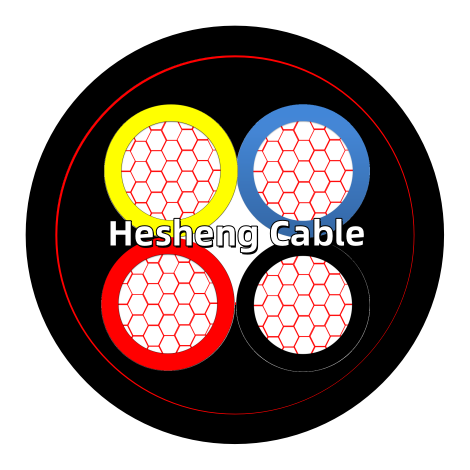

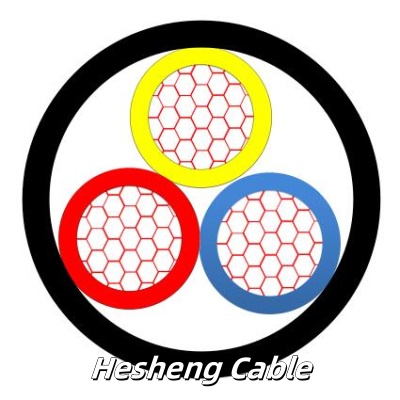

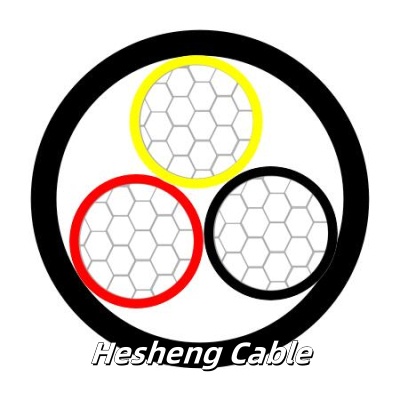

Cable Construction

|

- Solid or stranded, plain copper conductor - to DIN VDE 0295 cl. 1 or cl. 2, BS 6360 cl. 1 or cl. 2 and IEC 60228 cl. 1 or cl. 2 - PVC insulation DIV4 to HD 603.1 - Color coded to DIN VDE 0293-308, 0276 part 603 or HD 186 - Conductor color for 3+1/2 conductor J-type: green-yellow (1/2), brown, black, gray O-type: blue (1/2), brown, black, gray - PVC outer jacket DMV5 to HD 603.1 |

|

- Aluminium Conductor - VDE 0295 cl. 1 or cl. 2 (round and sector shaped), BS 6360/IEC 60228 cl. 1 or cl. 2 - PVC insulation type DIV4 acc. VDE0207 - Color coded to DIN VDE 0293 - PVC compound inner sheath - PVC outer sheath type DMV5 acc. VDE 0207 |

Technical Characteristics

- Working voltage: 600/1000 volts

- Test voltage: 4000 volts

- Flexing bending radius: 15 x Ø

- Static bending radius: 12 x Ø

- Flexing temperature: -5º C to +50º C

- Fixed installation temperature: - 40º C to +70º C

- Flame retardant: IEC 60332.1

- Insulation resistance: >100 MΩ x km

| AWG | Cores X Cross Section | NOMINAL OVERALL DIA | NOMINAL COPPER WEIGHT | NOMINAL CABLE WEIGHT | |

| MM2 | MM | KG/KM | KG | ||

| NYY-J NYY-O | 12 | 1x4re | 9.2 | 39 | 132 |

| 10 | 1x6re | 10.2 | 59 | 138 | |

| 8 | 1x10re | 11.2 | 97 | 184 | |

| 6 | 1x16re | 12.2 | 155 | 254 | |

| 4 | 1x25rm | 13.2 | 241 | 367 | |

| 2 | 1x35rm | 14.2 | 337 | 482 | |

| 1 | 1x50rm | 16.2 | 481 | 622 | |

| 2/0 | 1x70rm | 17.2 | 673 | 842 | |

| 3/0 | 1x95rm | 19.2 | 913 | 1102 | |

| 4/0 | 1x120rm | 21.2 | 1153 | 1322 | |

| 300mcm | 1x150rm | 23.2 | 1441 | 1612 | |

| 350mcm | 1x185rm | 25.2 | 1777 | 1982 | |

| 500mcm | 1x240rm | 28.2 | 2305 | 2552 | |

| 750mcm | 1x300rm | 30.2 | 2881 | 3202 | |

| - | 1x400rm | 34.2 | 3841 | 4002 | |

| - | 1x500rm | 38.2 | 4801 | 5102 | |

| 16 | 3x1.5re | 12.2 | 44 | 227 | |

| 14 | 3x2.5re | 13.2 | 73 | 277 | |

| 12 | 3x4re | 14.2 | 116 | 377 | |

| 10 | 3x6re | 15.2 | 174 | 482 | |

| 8 | 3x10re | 18.2 | 289 | 677 | |

| 6 | 3x16re | 19.2 | 462 | 882 | |

| 4 | 3x25rm | 24.2 | 721 | 1392 | |

| 2 | 3x35sm | 25.2 | 1009 | 1602 | |

| 1 | 3x50sm | 28.2 | 1441 | 2002 | |

| 2/0 | 3x70sm | 31.2 | 2017 | 2702 | |

| 3/0 | 3x95sm | 35.2 | 2737 | 3602 | |

| 4/0 | 3x120sm | 39.2 | 3457 | 4402 | |

| 300mcm | 3x150sm | 44.2 | 4321 | 4912 | |

| 350mcm | 3x185sm | 49.2 | 5329 | 6522 | |

| 500mcm | 3x240sm | 53.2 | 6913 | 8292 | |

| 4 | 3x25rm/16re | 25.2 | 875 | 1577 | |

| 2 | 3x35sm/16re | 26.2 | 1163 | 1702 | |

| 1 | 3x50sm/25rm | 30.2 | 1681 | 2327 | |

| 2/0 | 3x70sm/35sm | 35.2 | 2353 | 2902 | |

| 3/0 | 3x95sm/50sm | 37.2 | 3217 | 3902 | |

| 4/0 | 3x120sm/70sm | 42.2 | 4129 | 4902 | |

| 300mcm | 3x150sm/70sm | 47.2 | 4993 | 5802 | |

| 350mcm | 3x185sm/95sm | 51.2 | 6241 | 7402 | |

| 500mcm | 3x240sm/120sm | 59.2 | 8065 | 9702 | |

| - | 3x300sm/150sm | 66.2 | 10081 | 12002 | |

| 16 | 4x1.5re | 13.2 | 59 | 222 | |

| 14 | 4x2.5re | 14.2 | 97 | 302 | |

| 12 | 4x4re | 16.2 | 155 | 412 | |

| 10 | 4x6re | 17.2 | 231 | 522 | |

| 8 | 4x10re | 19.2 | 385 | 722 | |

| 6 | 4x16re | 22.2 | 615 | 1052 | |

| 4 | 4x25rm | 26.2 | 961 | 1652 | |

| 2 | 4x35sm | 28.2 | 1345 | 1862 | |

| 1 | 4x50sm | 31.2 | 1921 | 2502 | |

| 2/0 | 4x70sm | 35.2 | 2689 | 3302 | |

| 3/0 | 4x95sm | 38.2 | 3649 | 4502 | |

| 4/0 | 4x120sm | 42.2 | 4609 | 5502 | |

| 300mcm | 4x150sm | 47.2 | 5761 | 6882 | |

| 350mcm | 4x185sm | 52.2 | 7105 | 8462 | |

| 500mcm | 4x240sm | 59.2 | 9217 | 11002 | |

| 16 | 5x1.5re | 13.2 | 73 | 282 | |

| 14 | 5x2.5re | 15.2 | 121 | 362 | |

| 12 | 5x4re | 16.2 | 193 | 492 | |

| 10 | 5x6re | 18.2 | 289 | 652 | |

| 8 | 5x10re | 20.2 | 481 | 872 | |

| 6 | 5x16re | 23.2 | 769 | 1257 | |

| 4 | 5x25rm | 30.2 | 1201 | 1982 | |

| 2 | 5x35rm | 34.2 | 1681 | 2652 | |

| 16 | 7x1.5re | 14.2 | 102 | 372 | |

| 16 | 10x1.5re | 17.2 | 145 | 532 | |

| 16 | 12x1.5re | 18.2 | 174 | 582 | |

| 16 | 14x1.5re | 19.2 | 203 | 622 | |

| 16 | 16x1.5re | 20.2 | 231 | 692 | |

| 16 | 19x1.5re | 21.2 | 275 | 772 | |

| 16 | 21x1.5re | 22.2 | 303 | 852 | |

| 16 | 24x1.5re | 23.2 | 347 | 902 | |

| 16 | 30x1.5re | 24.2 | 433 | 1032 | |

| 16 | 40x1.5re | 28.2 | 577 | 1262 | |

| 16 | 61x1.5re | 32.2 | 879 | 1762 | |

| 14 | 7x2.5re | 16.2 | 169 | 462 | |

| 14 | 10x2.5re | 19.2 | 241 | 652 | |

| 14 | 12x2.5re | 20.2 | 289 | 732 | |

| 14 | 14x2.5re | 21.2 | 337 | 822 | |

| 14 | 16x2.5re | 22.2 | 385 | 932 | |

| 14 | 19x2.5re | 23.2 | 457 | 1002 | |

| 14 | 21x2.5re | 24.2 | 505 | 1052 | |

| 14 | 24x2.5re | 26.2 | 577 | 1122 | |

| 14 | 30x2.5re | 28.2 | 721 | 1302 | |

| 14 | 40x2.5re | 30.2 | 961 | 1702 | |

| 14 | 52x2.5re | 36.2 | 1249 | 2302 | |

| 14 | 61x2.5re | 38.2 | 1465 | 2602 | |

| 14 | 7x4re | 19.2 | 270 | 622 | |

| 14 | 7x6re | 21.2 | 404 | 862 | |

NYY vs NYCY vs NYCWY

The NYY cable is known for its robustness and durability, featuring a PVC (polyvinyl chloride) outer sheath that offers excellent mechanical protection. This makes it suitable for both indoor and outdoor installations, including direct burial in the ground. Its versatile construction allows it to be used in a variety of environments, providing reliable performance in residential and industrial settings.

On the other hand, the NYCY cable stands out with its flexible structure, designed primarily for applications where mobility and adaptability are required. This cable is often used in situations where frequent movement or repositioning is necessary, making it ideal for temporary installations or dynamic equipment. Its construction facilitates easy handling without sacrificing safety standards.

Lastly, the NYCWY cable combines the advantages of the NYCY with added fire resistance. With an additional layer of fire-retardant material, it offers enhanced safety in environments where fire hazards are a concern. This makes it particularly suitable for commercial buildings and high-risk areas, ensuring that electrical systems remain safe and dependable.

In summary, while NYY cables provide strong protection for fixed installations, NYCY cables cater to dynamic applications, and NYCWY cables integrate fire safety into flexible usage scenarios. Choosing the right cable depends on the specific needs of the application, ensuring optimal performance and safety standards.