German Standard: SY Steel Wire Braid Control Cable

product detail

Application and Description of SY Cable

SY Steel Wire Braid Cable is supplied to a diverse array of industries, including construction and building (frequently in airport settings), rail and transport infrastructure, transmission, distribution and power networks, as well as automation and process control. SY Cable is employed as an interconnecting cable for the measurement, control, and regulation of signals and control equipment. This braided control cable is frequently utilised on assembly and production lines, conveyors, in computer units and machine tool manufacture. The SY Cable's flexible and versatile design makes it an optimal choice for linking fixed and mobile equipment – as well as projects where fixed installations are required. With the appropriate protection (such as avoiding direct sunlight), SY Control Cable is suitable for outdoor installations. However, the SY Flex is most appropriate for use in dry or moist indoor environments.

Standard of SY Wire

BS6500, VDE0250

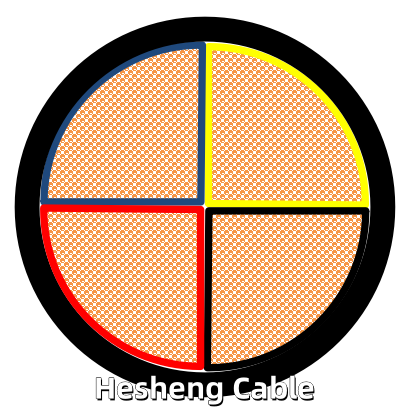

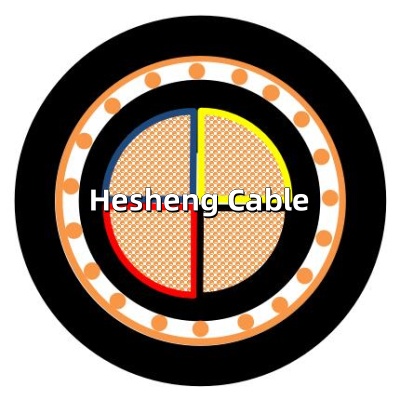

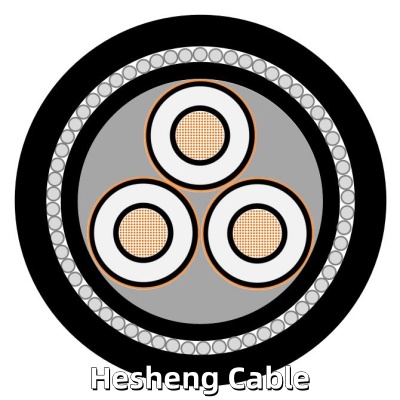

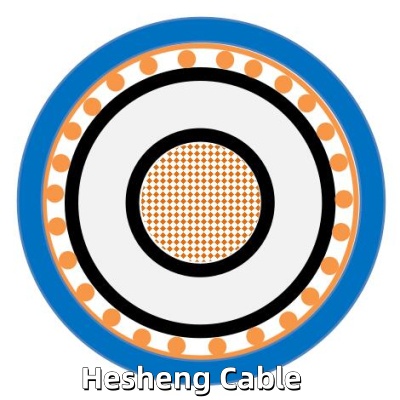

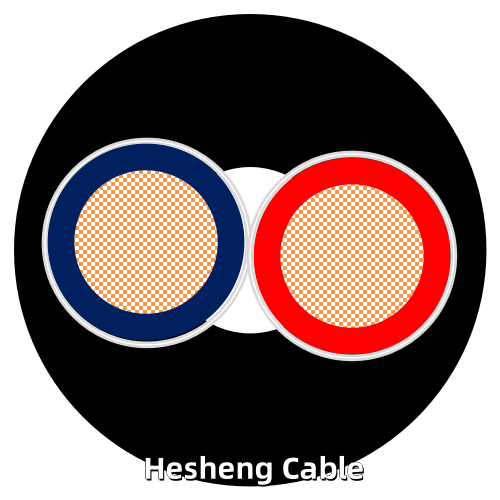

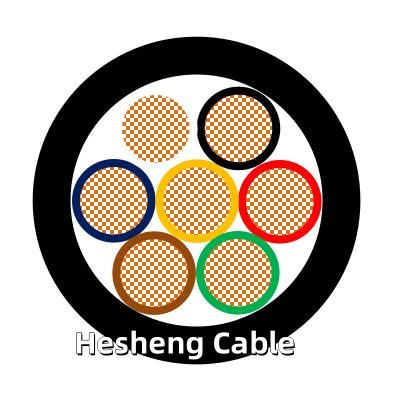

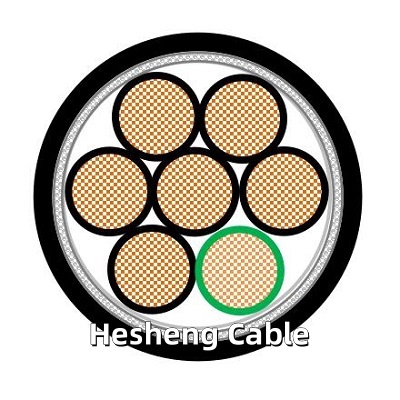

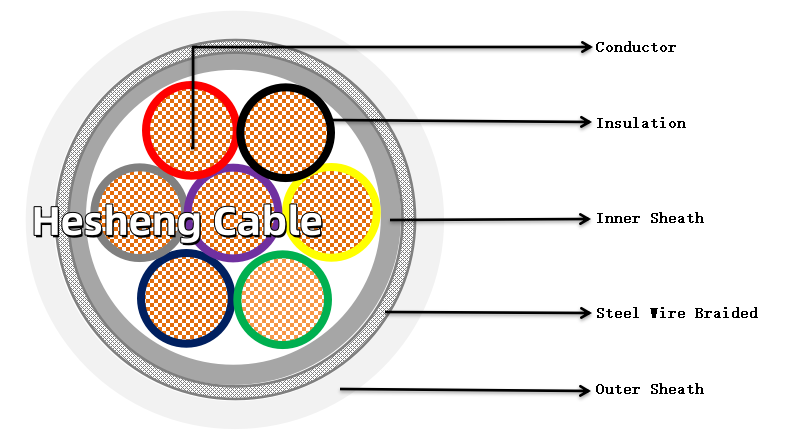

| Structure chart of SY Wire | SY Cable Construction |

|

- Plain copper conductor

|

Technical Characteristics

- Working voltage: 300/500 volts

- Test voltage: 3000 volts

- Minimum bending radius: 10 x Ø

- Flexing temperature: -15º C to +70º C

- Static temperature: -35º C to +70º C

- Short circuit temperature: +160º C

- Flame retardant: IEC 60332.3

- Insulation resistance: 20 MΩ x km

Datasheet of SY Cable

| AWG | No. of Cores x Nominal Cross Sectional Area # x mm2 | Diameter over Bedding mm | Diameter over Braid mm | Nominal Overall Diameter mm | Cable Weight kg / km |

| 20(16/32) | 12 x 0.5 | 9.8 | 10.8 | 12.5 | 216 |

| 20(16/32) | 18 x 0.5 | 11.3 | 12.5 | 14.4 | 300 |

| 20(16/32) | 25 x 0.5 | 13.8 | 15 | 16.9 | 402 |

| 20(16/32) | 30 x 0.5 | 14.3 | 15.5 | 17.8 | 456 |

| 20(16/32) | 35 x 0.5 | 16 | 17.2 | 20 | 587 |

| 20(16/32) | 41 x 0.5 | 17.6 | 18.8 | 21.6 | 673 |

| 20(16/32) | 50 x 0.5 | 18.5 | 19.7 | 22 | 696 |

| 20(16/32) | 60 x 0.5 | 20.1 | 21.3 | 24.3 | 897 |

| 18(24/32) | 12 x 0.75 | 10.9 | 11.9 | 13.8 | 268 |

| 18(24/32) | 18 x 0.75 | 13.2 | 14.4 | 16.3 | 390 |

| 18(24/32) | 25 x 0.75 | 15.7 | 16.9 | 19.2 | 523 |

| 18(24/32) | 30 x 0.75 | 16.2 | 17.4 | 19.7 | 574 |

| 18(24/32) | 35 x 0.75 | 18 | 19.2 | 21.5 | 686 |

| 18(24/32) | 50 x 0.75 | 21 | 22.2 | 24.9 | 911 |

| 18(24/32) | 60 x 0.75 | 22.4 | 23.9 | 26.5 | 1052 |

| 17(32/32) | 5 x 1.0 | 8 | 9 | 10.9 | 173 |

| 17(32/32) | 7 x 1.0 | 8.7 | 9.7 | 11.6 | 205 |

| 17(32/32) | 12 x 1.0 | 11.3 | 12.5 | 14.4 | 316 |

| 17(32/32) | 18 x 1.0 | 13.7 | 14.9 | 16.8 | 443 |

| 17(32/32) | 25 x 1.0 | 16.3 | 17.5 | 19.8 | 596 |

| 17(32/32) | 30 x 1.0 | 16.9 | 18.1 | 20.4 | 660 |

| 17(32/32) | 35 x 1.0 | 18.7 | 19.9 | 22.2 | 788 |

| 17(32/32) | 50 x 1.0 | 21.9 | 23.4 | 26 | 1072 |

| 17(32/32) | 60 x 1.0 | 23.7 | 25.2 | 27.8 | 1242 |

| 16(30/30) | 5 x 1.5 | 8.8 | 9.8 | 11.7 | 204 |

| 16(30/30) | 7 x 1.5 | 9.6 | 10.6 | 12.5 | 244 |

| 16(30/30) | 12 x 1.5 | 12.9 | 14.1 | 16 | 396 |

| 16(30/30) | 18 x 1.5 | 15.2 | 16.4 | 18.7 | 555 |

| 16(30/30) | 25 x 1.5 | 18.5 | 19.7 | 22 | 748 |

| 16(30/30) | 30 x 1.5 | 19.2 | 20.4 | 23.1 | 852 |

| 16(30/30) | 35 x 1.5 | 20.8 | 22 | 24.7 | 992 |

| 16(30/30) | 50 x 1.5 | 24.8 | 26.3 | 29.3 | 1382 |

| 16(30/30) | 60 x 1.5 | 26.4 | 27.9 | 30.9 | 1572 |

| 14(30/50) | 2 x 2.5 | 8.1 | 9.1 | 11.1 | 145 |

| 14(30/50) | 3 x 2.5 | 8.6 | 9.6 | 11.5 | 195 |

| 14(30/50) | 4 x 2.5 | 9.5 | 10.5 | 12.4 | 234 |

| 14(30/50) | 5 x 2.5 | 10.4 | 11.4 | 13.3 | 279 |

| 14(30/50) | 7 x 2.5 | 11.4 | 12.6 | 14.5 | 355 |

| 14(30/50) | 12 x 2.5 | 15.4 | 16.6 | 18.9 | 577 |

| 14(30/50) | 18 x 2.5 | 18.6 | 19.8 | 22.1 | 820 |

| 14(30/50) | 25 x 2.5 | 22.2 | 23.7 | 26.3 | 1132 |

| 14(30/50) | 30 x 2.5 | 23.5 | 25 | 27.6 | 1292 |

| 14(30/50) | 35 x 2.5 | 25.4 | 26.9 | 29.9 | 1542 |

| 14(30/50) | 50 x 2.5 | 29.9 | 31.4 | 34.8 | 2062 |

| 14(30/50) | 60 x 2.5 | 31.8 | 33.3 | 36.7 | 2352 |

| 12(56/28) | 2 x 4.0 | 10.9 | 11.9 | 13.9 | 242 |

| 12(56/28) | 3 x 4.0 | 11.6 | 12.9 | 14.9 | 314 |

| 12(56/28) | 4 x 4.0 | 12.8 | 14 | 15.9 | 386 |

| 12(56/28) | 5 x 4.0 | 14.1 | 15.3 | 17.6 | 480 |

| 12(56/28) | 7 x 4.0 | 15.4 | 16.6 | 18.9 | 589 |

| 10(84/28) | 2 x 6.0 | 12.3 | 13.5 | 15.5 | 318 |

| 10(84/28) | 3 x 6.0 | 13.1 | 14.3 | 16.3 | 409 |

| 10(84/28) | 4 x 6.0 | 14.5 | 15.7 | 18 | 510 |

| 10(84/28) | 5 x 6.0 | 16 | 17.2 | 19.5 | 619 |

| 10(84/28) | 7 x 6.0 | 18 | 19.2 | 21.5 | 791 |

| 8(80/26) | 2 x 10.0 | 15.4 | 16.6 | 19 | 469 |

| 8(80/26) | 3 x 10.0 | 16.6 | 17.8 | 20.2 | 623 |

| 8(80/26) | 4 x 10.0 | 18.5 | 19.7 | 22 | 781 |

| 8(80/26) | 5 x 10.0 | 20.5 | 21.7 | 24.4 | 980 |

| 8(80/26) | 7 x 10.0 | 22.5 | 24 | 26.6 | 1252 |

| 6(128/26) | 3 x 16.0 | 19.8 | 20.9 | 23.9 | 859 |

| 6(128/26) | 4 x 16.0 | 21.5 | 22.8 | 25.6 | 1042 |

| 6(128/26) | 5 x 16.0 | 24.2 | 25.5 | 28.7 | 1302 |

| 4(200/26) | 3 x 25.0 | 21.5 | 22.8 | 25.6 | 1112 |

| 4(200/26) | 4 x 25.0 | 23.9 | 25.2 | 27.3 | 1352 |

| 4(200/26) | 5 x 25.0 | 26.5 | 27.8 | 31.4 | 1742 |

| 4(200/26) | 5 x 35.0 | / | / | 36.1 | 3187 |

YY vs CY vs SY: a comprehensive comparison of control cables

when it comes to selecting the right control cable for your electrical systems, understanding the distinctions between yy, cy, and sy cables is crucial. each type offers unique features tailored to specific applications.

yy control cable: the yy control cable is characterized by its thermoplastic insulation and outer sheath, making it highly flexible and suitable for various environments. it is primarily used in industrial applications where low electromagnetic interference is a concern. furthermore, the yy cable excels in situations requiring a lightweight solution, ensuring ease of installation and handling.

cy control cable: unlike its yy counterpart, the cy control cable is equipped with an additional shielding layer. this feature makes it ideal for environments with high levels of electrical interference. the copper wire shielding not only protects the cable from external noise but also enhances signal quality, making it a popular choice for sensitive electronic equipment. additionally, cy cables are often used in applications requiring a high level of durability and resistance to environmental factors.

sy control cable: the sy control cable combines the best of both worlds, offering both shielding and flexibility. it is designed with a strong outer jacket to withstand physical stresses while providing excellent electrical performance. the sy cable is commonly used in automation systems and machinery where reliable communication and power supply are paramount. moreover, its robust design ensures longevity in even the most challenging industrial conditions.

in summary, the choice between yy, cy, and sy control cables should be based on specific application requirements. yy cables are excellent for lightweight and flexible needs, cy cables are perfect for shielding against interference, and sy cables offer durability with superior performance. by understanding these differences, you can make an informed decision that enhances the efficiency and reliability of your electrical systems.